Premiym Tea Packaging machines Solutions

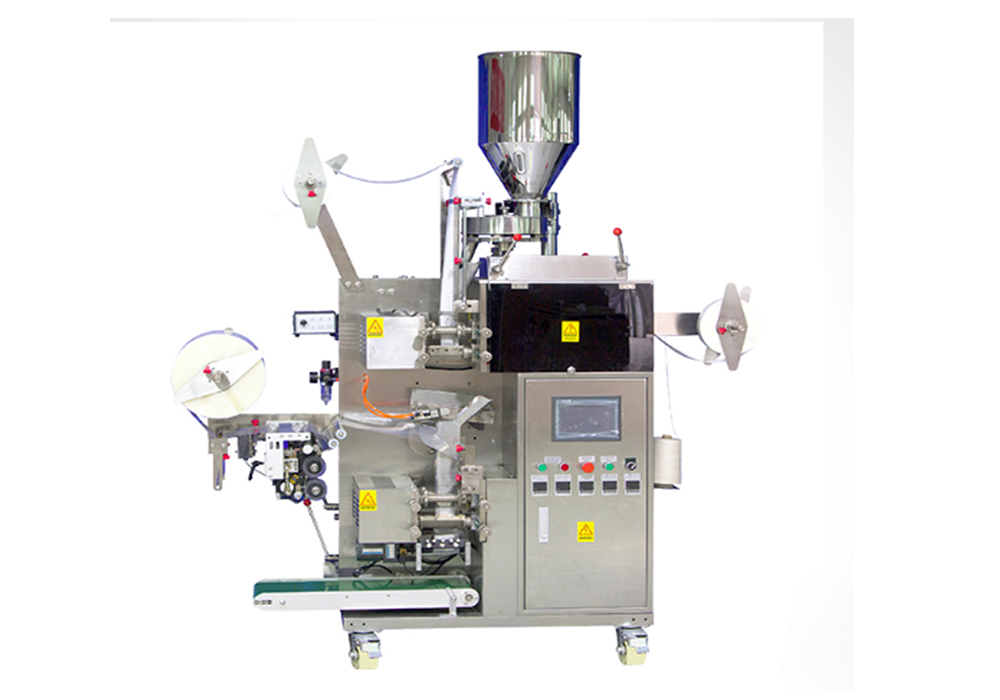

Our advanced tea packaging machines 🍵 technology provides the ultimate solution for manufacturers seeking high-speed production without sacrificing quality. By integrating ultrasonic sealing ⚡ and precision weighing ⚖️ systems, our machines ensure every package maintains maximum freshness and aroma.

Are These Tea tea packaging machines Challenges Holding You Back?

Identify the critical bottlenecks limiting your tea production efficiency and discover how our solutions eliminate each barrier

Poor sealing causes tea quality degradation and customer complaints

Manual processes create bottlenecks limiting production capacity

Inadequate preservation technology reduces product shelf life

Labor-intensive operations increase operational expenses significantly

Variable packaging results damage brand reputation and sales

Ready to eliminate these production barriers?

Discover Our SolutionsTea packaging machines Smart Solutions

Comprehensive automation technology designed specifically for tea packaging challenges, delivering measurable results from day one

Feature: Advanced gas replacement system removes oxygen to preserve freshness and extend shelf life significantly.

Advantage: Maintain optimal tea quality during storage and transportation while reducing spoilage rates.

Benefit: Increase product shelf life by 200% and reduce return rates by 85%.

Feature: Multi-head weighing technology with ±0.5g accuracy ensures consistent portion control.

Advantage: Eliminate product giveaway while maintaining customer satisfaction through consistent portions.

Benefit: Reduce material waste by 15% and increase profit margins by 8-12%.

Feature: Ultrasonic and heat sealing with real-time quality monitoring ensures perfect seal integrity.

Advantage: Prevent leakage and contamination while maintaining package aesthetics and functionality.

Benefit: Achieve 99.8% seal success rate and eliminate customer complaints about damaged packages.

Experience the power of integrated automation?

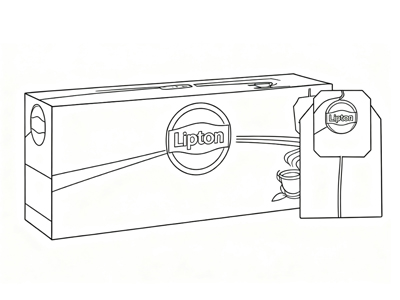

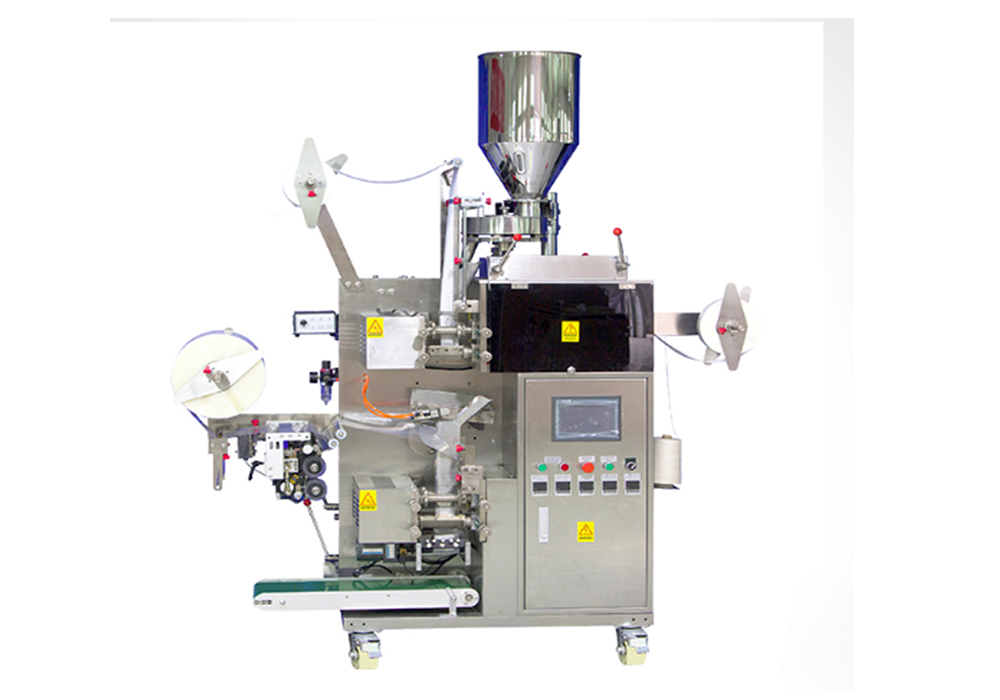

View Complete SolutionsComplete Tea Packaging Machines Range

From loose tea to premium tea bags, our comprehensive machine portfolio covers every tea packaging requirement with industry-leading performance

Loose Tea Packaging Machines

- Herbs packing with string and tag at speed

- Packing Speed:60 bags/min

- Automatic weighting & feeding

- Compacting structure, small floor space

Tea Bag Making Machines

- Pyramid and flat bag production

- 50-60 bags per minute speed

- String and tag attachment

- Ultrasonic sealing technology

Vacuum Packaging Solution

- Advanced vacuum chamber technology

- Extended shelf life preservation

- Premium tea brick formation

- Multiple package size options

Drip Tea Bag Packaging Machines

- Which has filter and alarm

- The vacuum performance is stable and reliable

- Quality inspection integration

- High-speed production capability

Need a custom machine configuration?

Configure Your SolutionMultiple Package Formats We Support

Versatile machinery designed to handle diverse packaging requirements, from traditional tea bags to premium gift packages

Need support for a unique package format?

Request Custom DevelopmentAdvanced Freshness Preservation Technology

Revolutionary preservation systems that extend shelf life by 300% while maintaining optimal tea flavor, aroma, and nutritional value

Nitrogen Flushing Process

Advanced gas replacement technology removes oxygen and replaces it with nitrogen to prevent oxidation

Technology Benefits

- Nitrogen Flushing: Removes 99.5% oxygen to prevent oxidation and preserve natural flavors

- Advanced Sealing: Multi-layer heat sealing ensures airtight package integrity

- Moisture Barrier: High-performance films protect against humidity damage

- Oxygen Removal: Vacuum technology eliminates air pockets for maximum preservation

Shelf Life Extension Comparison:

Want to see freshness technology in action?

Request Live DemonstrationTrusted by Tea Manufacturers Worldwide

Real results from global tea brands who transformed their operations with our packaging solutions

Premium Ceylon tea exporter upgraded to automated tea bag production line for international markets

"Production efficiency increased by 180% while maintaining premium quality standards for European markets"

Large-scale tea plantation implemented complete packaging automation for loose tea and gift packaging

"Reduced labor costs by 60% and eliminated quality inconsistencies across our product range"

Boutique organic tea company scaled operations with eco-friendly packaging solutions and smart automation

"Sustainable packaging technology helped us expand to new markets while maintaining organic certification"

Ready to join our success stories?

View Detailed Case StudiesTailored Solutions for Your Unique Needs

Our engineering team designs custom solutions that perfectly match your production requirements, space constraints, and business goals

Comprehensive assessment of your current processes, production goals, and technical requirements

Custom engineering design optimized for your specific tea types, packaging formats, and production volumes

Precision manufacturing with quality control at every stage, using premium components and materials

Professional installation, comprehensive testing, operator training, and performance optimization

Tea Packaging Applications & Samples

Need a completely custom solution?

Consult Our EngineersIntelligent Control System

Advanced automation technology with intuitive interfaces, real-time monitoring, and predictive maintenance capabilities

Smart Control Features

Feature: Multi-language touchscreen interface with one-touch recipe management and automated parameter adjustment.

Advantage: Minimize operator training time while maximizing production consistency and quality control.

Benefit: Reduce setup time by 75% and eliminate human errors that cost $5,000+ per incident.

Experience the future of packaging automation?

Explore Smart Technology🌱 Sustainable & Eco-Friendly Solutions

Leading the industry toward environmentally responsible packaging with energy-efficient machinery and biodegradable material support

Compatible with PLA, PET, and compostable films for eco-conscious packaging

Optimized for recyclable packaging materials reducing environmental impact

Advanced energy-saving technology reduces consumption by 30% versus industry standard

Optimized processes minimize emissions while maintaining production efficiency

Waterless cleaning systems and minimal water usage in all operations

ISO 14001 certified environmental management systems and processes

Comprehensive Service Support

End-to-end support from initial consultation to ongoing maintenance, ensuring maximum uptime and optimal performance

- Needs Analysis

- Solution Design

- ROI Calculation

- Quote Service

- Professional Installation

- Performance Testing

- Quality Verification

- Acceptance Confirmation

- Operation Training

- Maintenance Guidance

- Technical Documentation

- Safety Protocols

- Remote Diagnostics

- Parts Supply

- Upgrade Services

- Technical Hotline

Need immediate support or consultation?

CONTACT SERVICE TEAMIndustry Certifications & Quality Assurance

Comprehensive certifications ensuring global compliance and giving you confidence in your investment

European Conformity certification ensures equipment meets EU safety, health, and environmental protection standards for seamless market access.

International quality management certification validates consistent processes and continuous improvement culture for reliable performance.

Food-grade materials and manufacturing processes meet strict FDA requirements for food packaging equipment and US market access.

Third-party verification of manufacturing processes and quality control by global leader SGS provides independent validation.

Calculate Your ROI with Our Solutions

Discover the financial impact of automation with our ROI calculator - most clients see positive returns within 12-18 months

💰 Savings Analysis

Want a personalized ROI analysis?

Schedule ROI ConsultationProfessional Tea Packaging Process

Optimized workflow designed for maximum efficiency, quality control, and product safety at every stage

🎬 Tea Packaging Videos

Watch our advanced tea packaging machines in action - from loose leaf to tea bags, see the precision and efficiency of NEWIDEA PACK solutions

Automatic Tea Bag Packaging Machine

High-speed production of pyramid and flat tea bags with ultrasonic sealing technology for premium tea brands.

Loose Leaf Tea Flow Pack System

Precision weighing and sealing system for loose leaf tea packaging with nitrogen flushing for freshness preservation.

Tea Tin Can Filling & Sealing

Automated tin can filling system for premium loose leaf tea with precise weight control and vacuum sealing.

Tea Pouch Packaging Line

Complete packaging line for stand-up pouches with zipper closure, perfect for premium tea blends and herbal teas.

📊 Our Tea Packaging Solutions by the Numbers

Ready to see these machines in your facility?

Schedule a Live DemoConfigure Your Perfect Tea Packaging Solution

Interactive tool to design your ideal packaging line based on your specific requirements and constraints

Step 1 of 5: Production Requirements

20% CompleteConfiguration Summary:

Real-time Preview:

Your configuration is complete! We'll contact you within 24 hours.

Frequently Asked Questions

Get instant answers to common questions about our tea packaging solutions, installation, and support services

Our machines are specifically designed for tea packaging with advanced nitrogen flushing, precision weighing (±0.5g), and smart sealing technology. We offer 15+ years of specialized experience, multilingual support, and comprehensive training programs that competitors don't match.

Typical installation takes 3-5 days including setup, testing, and operator training. Our engineers handle everything from unpacking to final production runs, ensuring your team is fully trained before we leave.

Comprehensive 3-day training program covering operation, maintenance, troubleshooting, and safety protocols. We provide multilingual manuals, video tutorials, and ongoing technical support via phone and remote diagnostics.

Yes, our equipment handles loose leaf, CTC, powder, and herbal teas. Package formats include pillow bags, stand-up pouches, pyramid bags, vacuum bricks, and custom formats. Quick changeover systems allow multiple products on the same line.

2-year comprehensive warranty covering parts and labor, plus lifetime technical support. Extended warranty options available. We maintain spare parts inventory globally and offer 24/7 remote diagnostics for immediate troubleshooting.

Yes, we offer flexible financing through our partner banks including lease-to-own, installment payments, and trade-in programs. Our finance team works with customers to structure payments that match cash flow and ROI projections.