Surprise 25~50 KG Salt Packaging Line Choosen Like This

The classification of salt has a guiding effect on the Salt Packaging Line

Salt is an essential additive in current industrial and agricultural production and people’s lives. The packaging demand for salt in various industries is increasing day by day. Today, we will talk about how to make more accurate judgments about the packaging needs of our salt products.

Salt is a widely used mineral that is widely used in industrial production, agriculture, and food processing. According to different classification standards, salt can be divided into the following categories and has their own characteristics:

- Industrial salt: Industrial salt is mainly used in fields such as chemical production, leather processing, glass manufacturing, and metallurgical industry. This type of salt is usually processed to remove substances harmful to the human body. Industrial salt particles are generally larger and have relatively low purity requirements, allowing for a certain degree of impurities.

- Agricultural salt: Agricultural salt is mainly used in farmland irrigation, soil improvement, and animal husbandry. He can help regulate the acidity and alkalinity of the soil, improve the yield and quality of crops, and contain a certain amount of trace elements, which help promote plant growth. The particles of agricultural salt are generally large, with relatively low purity, and may contain certain impurities.

- Edible salt: Edible salt is widely used in cooking and Food processing. According to different processing methods and sources of raw materials, edible salt can be divided into rock salt, sea salt, lake salt and industrial refined salt. Common edible salt is refined and has high

Purity and clear crystal structure, with fine particles and no harmful substances or heavy metals.

In the field of Salt packaging Line, regardless of the type of salt, the following issues need to be noted:

- Selection of packaging materials: Packaging materials suitable for salts should have characteristics such as moisture resistance, heat resistance, and leakage resistance.

- Sealing: Ensure that the packaging material has good sealing to avoid moisture and contamination of salt products. Packaging can be done using methods such as heat sealing.

- Measurement accuracy: During the packaging process, it is necessary to ensure the high accuracy of the measuring equipment used to avoid inaccurate weighing.

- Complete label information: The packaging should include necessary labels, including product name, specifications, origin, production date, shelf life, and other information, so that consumers can understand the basic information of the product.

- Prevention of moisture: Try to avoid salt products coming into contact with water or moisture to avoid problems such as clumping and reduced quality. Moisture-proof agents, desiccants, and other methods can be used to prevent moisture. Especially in salt storage silos and finished product storage warehouses, attention should be paid to improving moisture-proof measures.

- Shelf life management: Based on the characteristics of salt products, the shelf life of the product is reasonably set, and management and monitoring are carried out to ensure the stable quality of the product during the shelf life.

- Packaging Environmental Protection: Choose recyclable and interpretable packaging materials, and promote environmental awareness to reduce the generation of packaging waste.

By paying attention to the above points, it can be ensured that salt products can maintain their quality and effectiveness during the packaging process, meeting the needs of different application fields.

The setting of the salt packaging line for weighing 25-50 kilograms should follow the following process.

- Confirm if there is sufficient space for the salt packaging line setting up site: there should be no less than 300 square meters of site space, and the height of the factory should not be less than 5 meters.

- Confirm the physical properties of salt products, mainly particle size and density, which directly determine the selection of weighing system.

- Packaging bag determination:

I. Material and sealing method of packaging bags: The materials of packaging bags include:

A. Single side laminated woven

B. Double sided laminated woven

C. Non laminated woven fabric

D. Kraft paper Kraft paper

E. PE

F. Does the bag have a PE lining

II.Sealing method: heat sealing, sewing, taping

III. Type of packaging bag: 1 flat bag 2 gusseted bag 3 flat bottom bag

IV. Size and weight of packaging bag. - Output requirements

- Semi automatic or fully automatic selection

After confirming all the details above, you can arrange the corresponding combination of the entire production line according to your own needs.

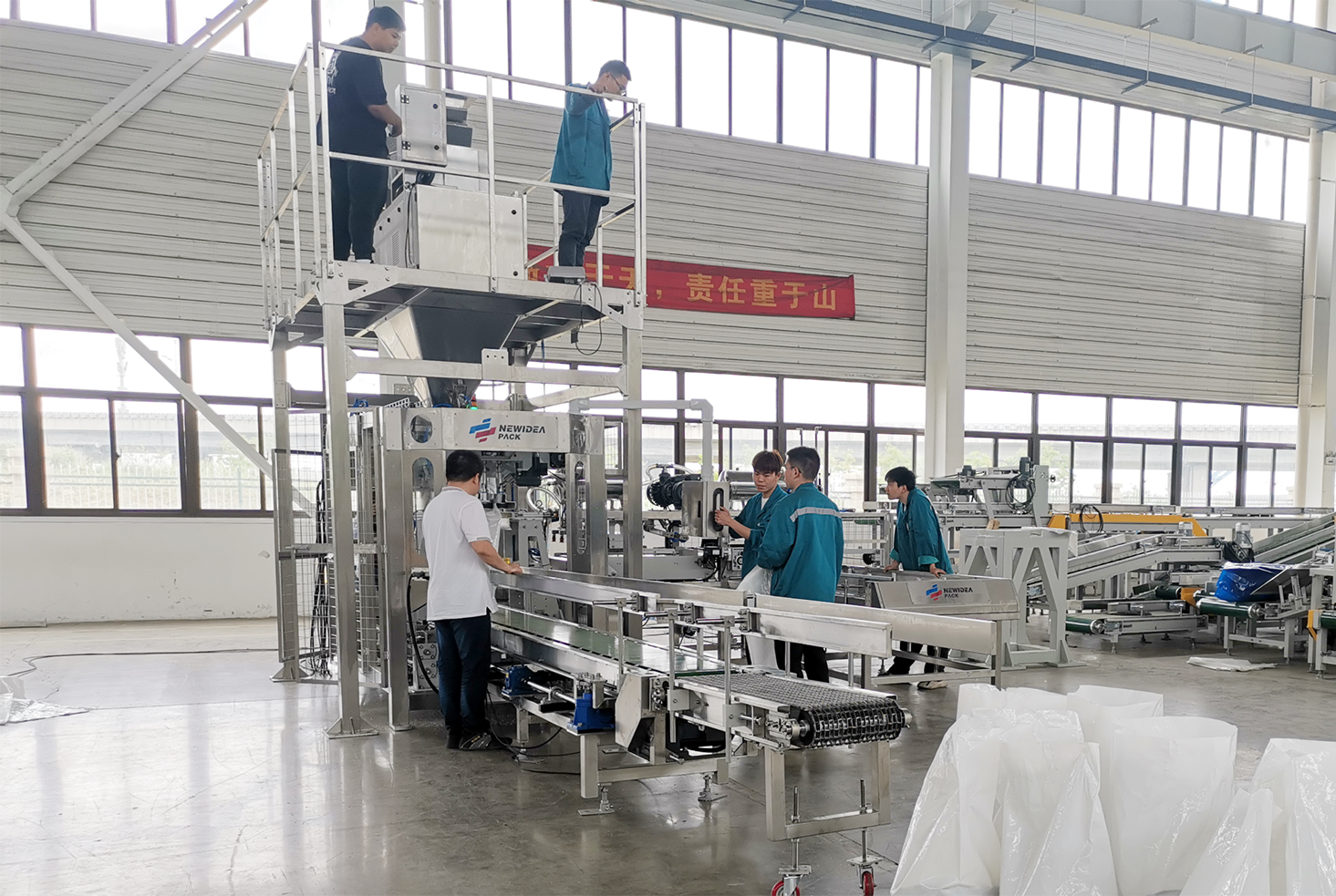

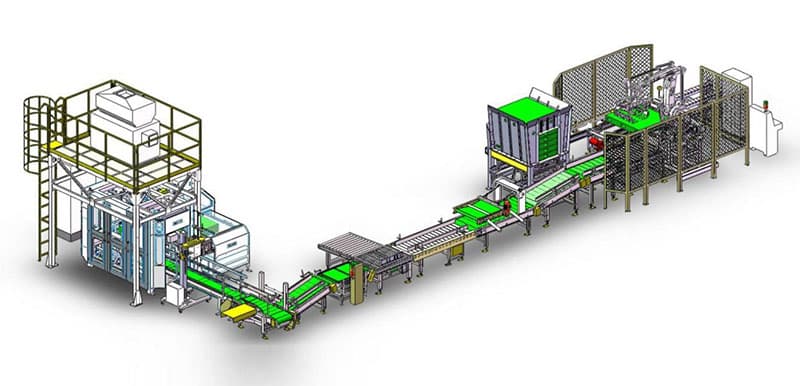

Composition of Salt Packaging Line

A complete automatic salt packaging line for large bag packaging includes storage silos, weighing systems, packaging machines, sealing machines, rewinding machines, weight detection machines, removal machines, metal detection machines, removal machines, packaging shaping machines, inkjet printers, palletizing robots, pallet libraries, and film wrapping machines.

The salt packaging line can effectively improve production efficiency, significantly reduce labor costs, and at the same time, it has high accuracy and environmental protection. I hope this article can provide you with assistance in selecting models and setting up production lines. If you need further one-on-one service, please contact us.