Open-mouth bagging machine

We provide stable, efficient, intelligent, automated and integrated

5/10/20/25/50kg open-mouth bagging machine solutions which .

Are These open-mouth bagging machine Challenges Holding You Back?

Identify the critical bottlenecks limiting your open-mouth bagging production efficiency and discover how our solutions eliminate each barrier

Affects the production environment and personnel health

High personnel training costs and high risk of errors

Delayed maintenance affects production progress

Difficulty in achieving centralized control and efficient management

Poor equipment compatibility and difficulty in meeting customized production needs

Ready to eliminate these production barriers?

Discover Our Solutionsopen-mouth bagging machine Smart Solutions

Comprehensive automation technology designed specifically for big-bag packaging challenges, delivering measurable results from day one.

Feature: Equipped with a multi-language HMI interface, remote diagnosis module , and capable of connecting to the central computer.

Advantage: It has a low operation threshold , high operation and maintenance efficiency (reducing fault diagnosis time by over 60%), and precise management.

Benefit: It enables customers to optimize labor costs, increase equipment utilization rate to over 90%, and upgrade management decision-making.

Feature: Adopting high-precision weighing sensors and intelligent algorithms, it supports dynamic real-time weighing of 25-50kg large bags (with an error within ±0.2%)

Advantage: Featuring automatic calibration and closed-loop control with the filling system. It is compatible with various materials.

Benefit: It helps customers control material costs (saving over 3.6 tons of materials annually), ensure quality compliance.

Feature: with auxiliary equipment, and equipped with an intelligent error-proof mechanism, it features smooth workflow, wide adaptability, and high stability (failure rate < 5%)

Advantage:It helps customers significantly increase production capacity (2-3 times higher than manual operation), maximize labor cost savings.

Benefit: Ensure the product qualification rate reaches over 99.5%.

Experience the power of integrated automation?

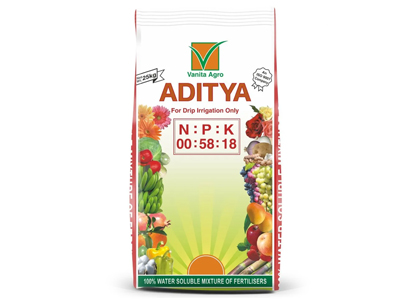

View Complete SolutionsYour Product

Whether your product is granular or powdered type, we have the tailor-made solution for you.

Granular materials

Powder materials

Open-mouth bagging machine

We provide stable, efficient, intelligent, automated and integrated 5/10/20/25/50kg open mouth bagging solutions which can realize automatic bagging, weighing, sealing, robotic palletizing and automatic pallet wrapping processes. This helps you to save labor cost, increase productivity and get standardize products.

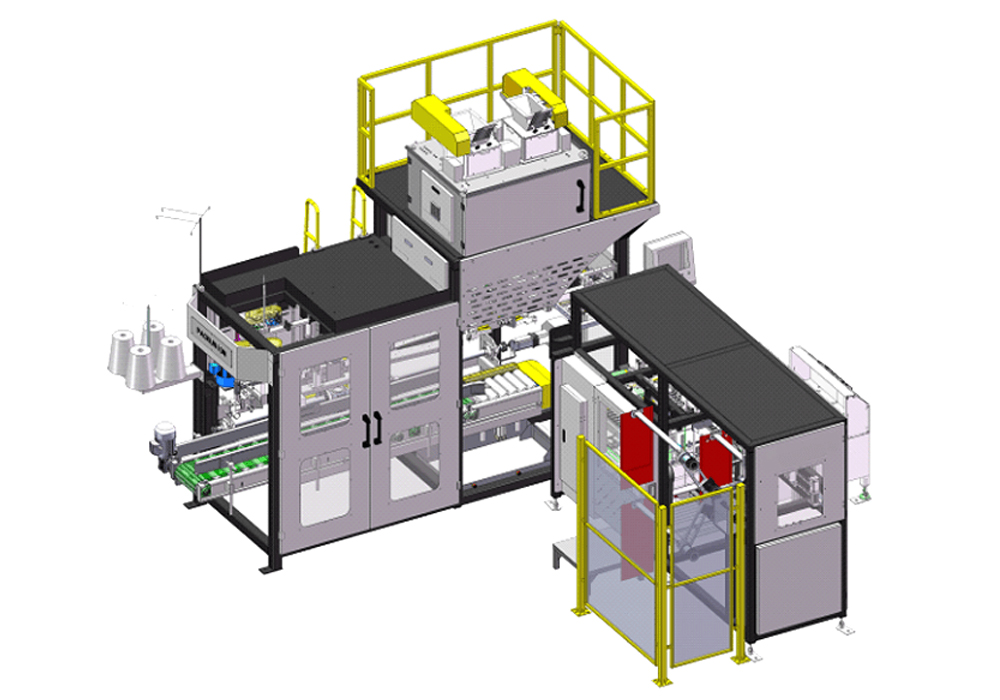

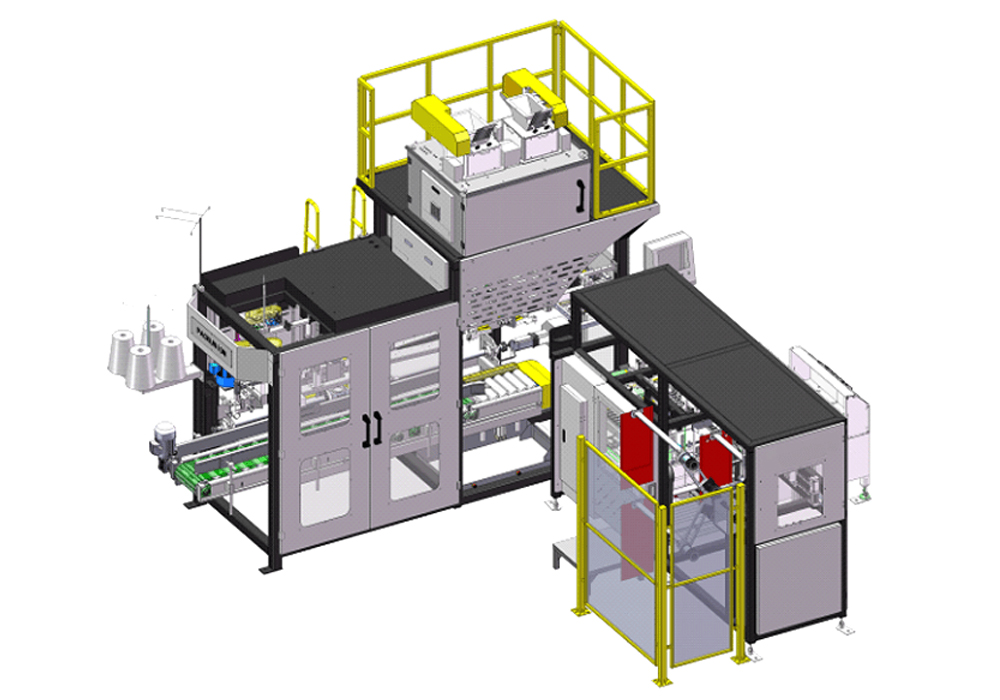

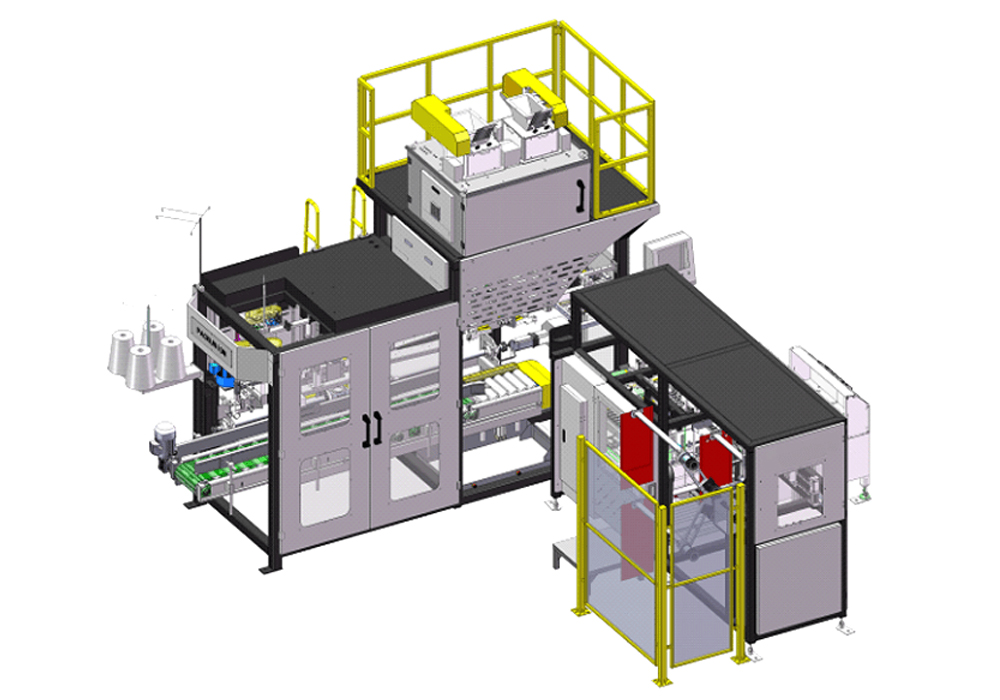

NGA-750 25-50kg Granule Automatic Bagging Machine

- Bagging machine is for 25-50kg granular products packed in flat open mouth bags

- Max Speed: 750 bph

- Multi language friendly HMI

- It can be connected with automatic palletizing and wrapping system

NGA-900 5-25kg Automatic Bagging Machine

- Completely automatic process of weighing, loading bag, opening bag, filling and sewing bag.

- Max Speed:900 bph

- Optional remote diagnosis function

- Using touch screen +PLC control

NGA-850 25-50kg Granule Automatic Bagging Machine

- High level automatic weighing, bag loading, bag opening, filling, sewing or heat sealing.

- Max Speed:850 bph

- Can place 500-600 bags, improve the efficiency.

- Multi language friendly HMI, easy to operate.

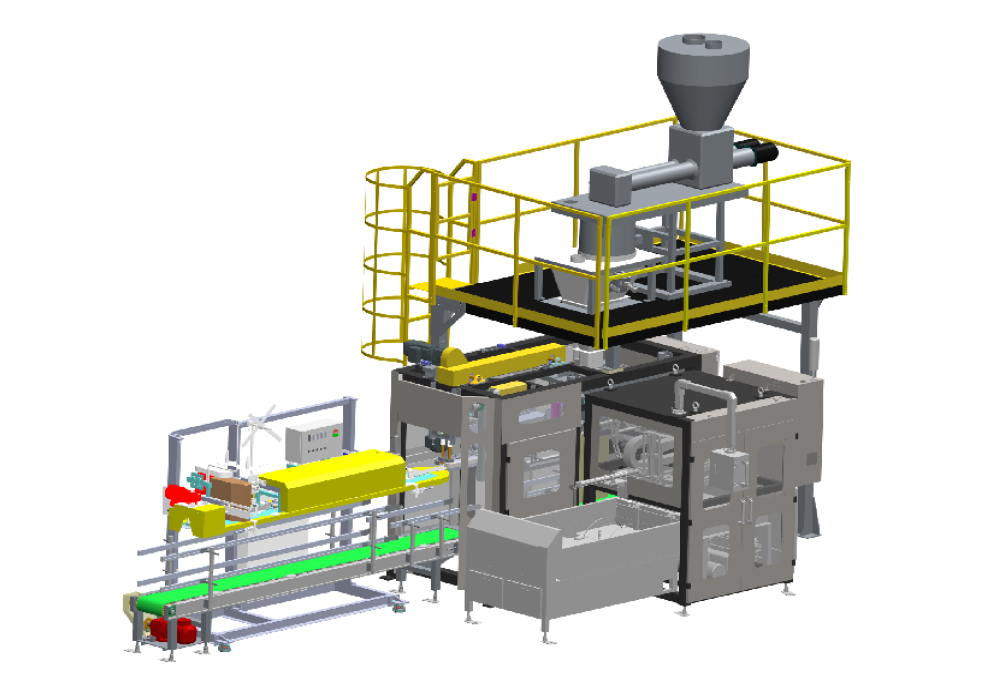

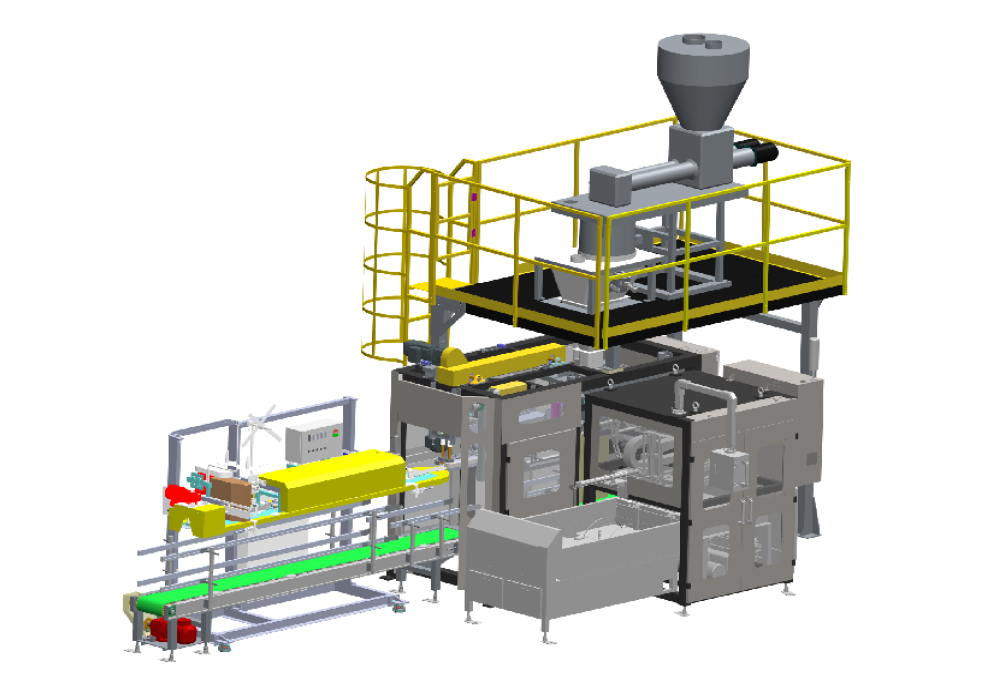

NPA-360 25-50kg Powder Automatic Bagging Machine

- Adopting horizontal double screw feeding, with bucket metering, fast weighing speed and high precision.

- Max Speed: 360 bph

- With automatic fault alarm function

- Customize the packaging line according your factory scene and individual requirements.

Need a custom machine configuration?

Configure Your SolutionOpen-mouth bagging machine

NPA-180 25-50kg Powder Automatic Bagging Machine

- Max Speed: 180 bph

- Packing weight: 25kg-50kg

Multiple Package Formats We Support

Pre-made open-mouth bags is one of the most popular flexible packaging type in the world, especially in 5-50kg big package industries. There are verious bag types and seal types for those bags, NEWIDEA PACK have completely series of open bag mouth bagging machine can meet your individual packaging demand.

Need support for a unique package format?

Request Custom DevelopmentCompact Bag-Clamping Design

The automatic packaging machine adopts a compact bag-clamping design to seal the gap between the bag and the discharge port, reducing dust emission from the source and achieving environmental protection and high efficiency in production.

Dust Collection System

1.Precise Dust Capture.2.Efficient Dust Treatment.3.Clean Air Discharge / Dust Recycling.

Technology Benefits

- Dust Control at Source, Reducing Initial Pollution: Compact bag-clamping seals bag and port, blocks 25-50kg dusty material escape, preventing initial workshop pollution.

- Real-Time Capture, Preventing Diffusion Pollution: Multiple dust ports capture/treat dust during filling/bag replacement, stopping spread and reducing secondary pollution.

- Compliance with Standards, Lowering Regulatory Risks: Dual dust control meets national/industry standards, avoiding environment damage, penalties and reducing air impact.

Dust Control Comparison

Want to see freshness technology in action?

Request Live DemonstrationTailored Solutions for Your Unique Needs

Our engineering team designs custom solutions that perfectly match your production requirements, space constraints, and business goals

Comprehensive assessment of your current processes, production goals, and technical requirements

Custom engineering design optimized for your specific open-mouth bagging,Material, packaging formats, and production volumes

Precision manufacturing with quality control at every stage, using premium components and materials

Professional installation, comprehensive testing, operator training, and performance optimization

open-mouth bagging applications & samples

Need a completely custom solution?

Consult Our EngineersIntelligent Control System

Advanced automation technology with intuitive interfaces, real-time monitoring, and predictive maintenance capabilities

Smart Control Features

Feature: Multi-language touchscreen interface with one-touch recipe management and automated parameter adjustment.

Advantage: Minimize operator training time while maximizing production consistency and quality control.

Benefit: Reduce setup time by 75% and eliminate human errors that cost $5,000+ per incident.

Experience the future of packaging automation?

Explore Smart Technology🌱 Sustainable & Eco-Friendly Solutions

Leading the industry toward environmentally responsible packaging with energy-efficient machinery and biodegradable material support

Compatible with PLA, PET, and compostable films for eco-conscious packaging

Optimized for recyclable packaging materials reducing environmental impact

Advanced energy-saving technology reduces consumption by 30% versus industry standard

Optimized processes minimize emissions while maintaining production efficiency

Waterless cleaning systems and minimal water usage in all operations

ISO 14001 certified environmental management systems and processes

Comprehensive Service Support

End-to-end support from initial consultation to ongoing maintenance, ensuring maximum uptime and optimal performance

- Needs Analysis

- Solution Design

- ROI Calculation

- Quote Service

- Professional Installation

- Performance Testing

- Quality Verification

- Acceptance Confirmation

- Operation Training

- Maintenance Guidance

- Technical Documentation

- Safety Protocols

- Remote Diagnostics

- Parts Supply

- Upgrade Services

- Technical Hotline

Need immediate support or consultation?

CONTACT SERVICE TEAMIndustry Certifications & Quality Assurance

Comprehensive certifications ensuring global compliance and giving you confidence in your investment

European Conformity certification ensures equipment meets EU safety, health, and environmental protection standards for seamless market access.

International quality management certification validates consistent processes and continuous improvement culture for reliable performance.

Food-grade materials and manufacturing processes meet strict FDA requirements for food packaging equipment and US market access.

Third-party verification of manufacturing processes and quality control by global leader SGS provides independent validation.

🎬 open-mouth bagging videos

Watch our advanced open-mouth bagging machines in action, see the precision and efficiency of NEWIDEA PACK solutions

Semi-Auto Bagging Machine

NGS-700 Suitable for of 25-50kg salt, sugar ,animal feed , grains, chemical industries and other granular products’s quantitative packing.

Automatic Bagging Machine

It is automatic bag feeding, weighing, filling, sealing and conveying.It widely used for 5-25kg granular products packed in flat or gusseted bags.

Granule Automatic Bagging

It is an high speed automatic bagging machine for 25-50kg bags, with automatic weighting,filling , bagging, and sealing system.

Powder Automatic Bagging

The process of weighing, bag loading, bag opening, material discharging and bag sewing is fully automated.

📊 Our open-mouth bagging Solutions by the Numbers

Ready to see these machines in your facility?

Schedule a Live DemoFrequently asked questions

Get instant answers to common questions about our open-mouth bagging machines solutions, installation, and support services

It is deponds on your product materials, target weigth and bag type.You can contact with us, we will according your information answer you.

We have 5-25kg , 25-50kg bagging machines, actually we consider target weight ,also consider your bag size to offer you the correct model.

Most of our machines can pack various bag types.Please click to know more about the bag type and machines.

One machine can pack different products, but they must be have same materials characteristic.

For some dusty granular , or powdered materials ,our machine equip with many dust removal mouth , can be connected with the dust collectors.

Yes, we can send our engineers go to your factory for installation, commissioning, and trainning.