How Does A Multi-Head Weigher Work

What is a Multihead Weigher ?

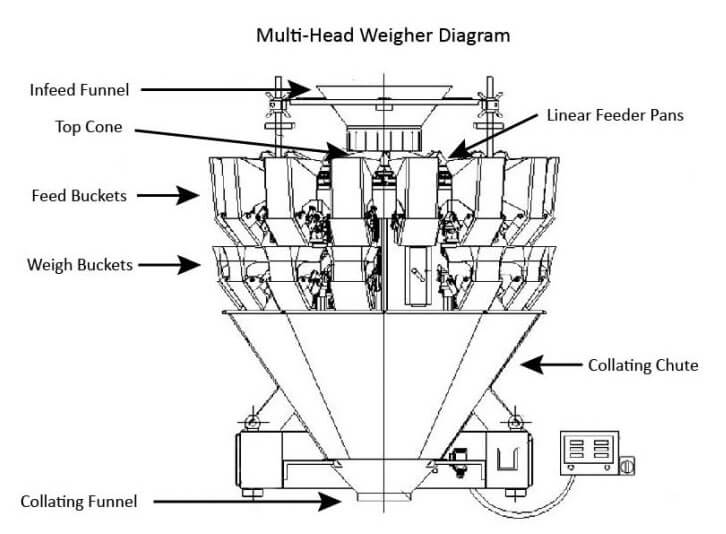

A mult-ihead weigher is a weighing machine that can quickly and accurately measure the weight of items to be packaged. As an important component of the packaging machine, it is usually used in items packaging projects that require high weighing accuracy

The multihead weigher was invented by Ishida in 1970, and it was first used in the field of food packaging. With the increasing demand for packaging accuracy in various fields, the multihead weigher is playing its function in more fields. Usually, it will form a complete packaging system together with a packaging machine (especially a vertical seal packaging machine).

How a Multihead Weigher Works ?

The multihead weigher work by matching the weights of multiple hoppers to ensure that the preset package weight is reached. The multihead weigher has multiple small hoppers, and continuously obtains a part of the material to be packaged from the main hopper. Due to the characteristics of the material itself (difference in monomer volume, shape, weight) and the uneven feeding of the hopper, the weight of the material to be packaged distributed to each small hopper will be different.

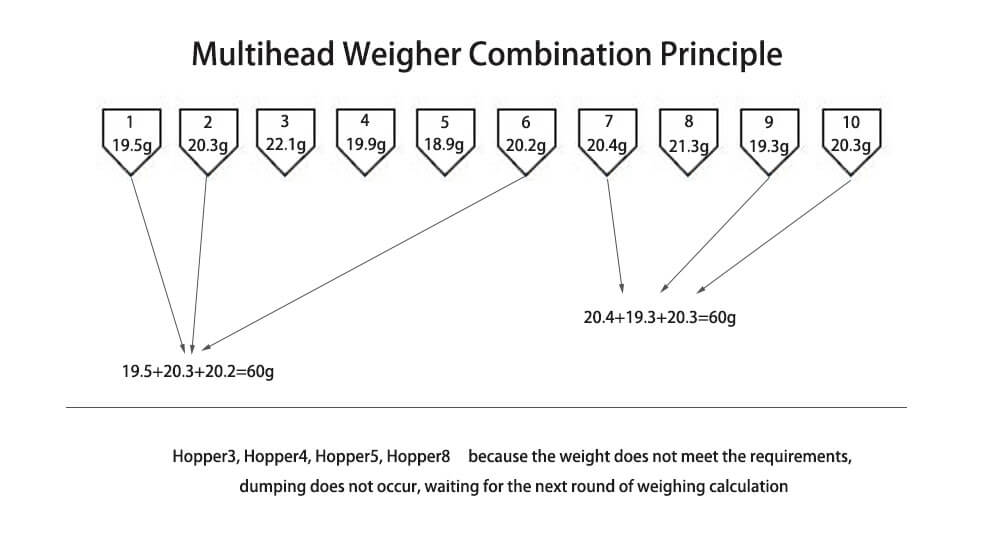

Suppose we preset a package with a net weight of 60 grams, and our multihead weigher has 10 small hoppers for weighing. After weighing, the weights of the items to be packaged in each small hopper are 19.5, 20.3, 22.1, 19.9, 18.9, 20.2, 20.4, 21.3, 19.3, 20.3

At this time, the microcomputer processor of the multihead weigher will calculate the weighing value of the above 10 small hoppers to obtain the result closest to 60 grams. Then the correct weighing selection should be hopper 1 + hopper 2 + hopper 6; Hopper 7 + Hopper 9 + Hopper 10. As shown below.

Working steps of the multihead weigher

According to the working principle of the above figure, hopper 1, hopper 2 and hopper 6 together form a standard weight to be packaged. Hopper 7, hopper 9, hopper 10 together constitute a standard weight to be packaged. At this time, their hoppers will tilt to dump the contents of the hoppers into the bags. The remaining hopper 3, hopper 4, hopper 5, and hopper 8 cannot accurately match the weight, so the hopper does not tilt during this round of weighing.

The main hopper is fed for the next round. The 6 small hoppers that were empty after dumping are filled again. At this time, the microcomputer processor of the multihead weigher performs the weighing calculation again and selects 3 suitable small hoppers for Dump, and then the material is packaged.

If you want to have an in-depth understanding of the packaging machine industry or are interested in learning more about packaging machines, please contact our professional engineers and we will give you the answer you want. And all this for free!