Professional Drip coffee bag Packaging machine Solutions

High-Performance ±0.1g Precise Drip Coffee Bag packaging machine Systems

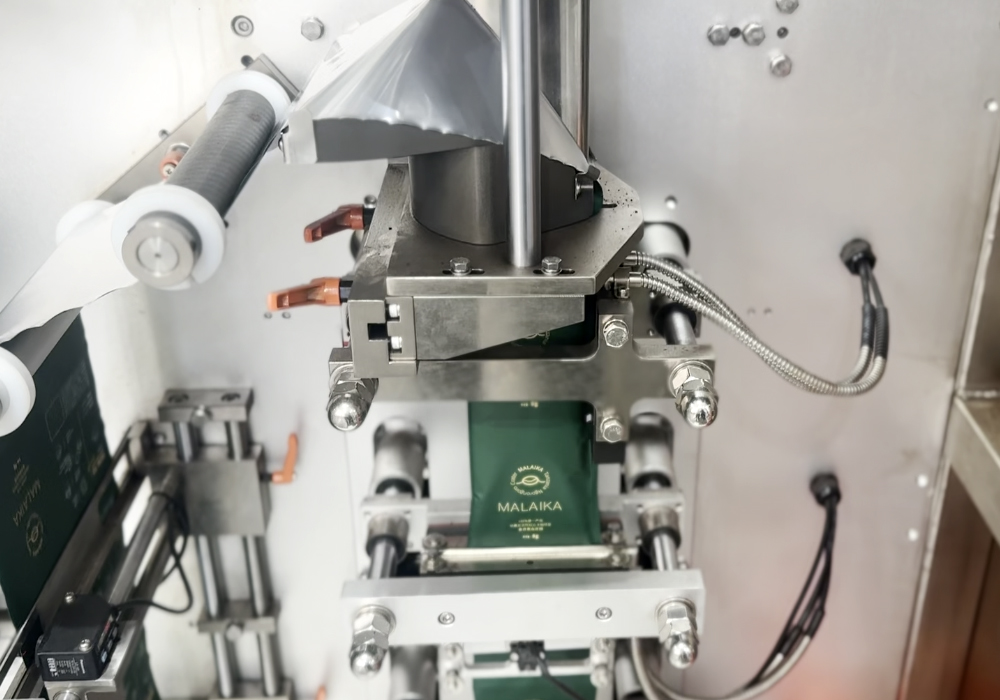

Upgrade your coffee business with the NewIdeaPack ultrasonic Drip coffee bag packaging machine. Designed for high-speed drip bag production, this packaging machine delivers ±0.1g filling accuracy and superior ultrasonic sealing to keep your coffee fresh and professional

Precision Engineering That Delivers Results

Industry-leading specifications that ensure consistent quality, maximum efficiency, and superior freshness preservation for your drip coffee packaging operations.

**Feature:** High-precision weighing system ensures consistent coffee portions in every bag.

**Advantage:** Eliminates waste and guarantees uniform taste experience.

**Benefit:** Reduce material costs by 15% while maintaining premium quality standards.

**Feature:** High-speed production capability with C80E (65 bpm) and C80PRO (90 bpm) models.

**Advantage:** Meet large-scale demand while maintaining quality consistency.

**Benefit:** Increase daily output by 300% compared to manual packaging methods.

**Feature:** Advanced nitrogen flushing technology creates oxygen-free environment.

**Advantage:** Preserves coffee aroma and flavor for extended shelf life.

**Benefit:** Extend product freshness by 6+ months, reducing returns and waste.

**Feature:** Proprietary innovations including ultrasonic sealing and smart controls.

**Advantage:** Access to cutting-edge technology unavailable elsewhere.

**Benefit:** Stay ahead of competition with exclusive technological advantages.

Ready to experience precision packaging?

Get Technical SpecificationsSee Drip Coffee Bag packaging Machine in Action

Watch real production footage and customer testimonials showcasing the precision, speed, and reliability of our drip coffee packaging machines.

Want to see more production videos?

Request Live DemoDrip Coffee Bag packaging machine Detailed Model Comparison

Compare specifications, capabilities, and features to choose the optimal machine for your production requirements and business goals.

| Specification | ND-C60Y | ND-C60E | ND-C80E | ND-C80PRO | Advantage |

|---|---|---|---|---|---|

| Production Speed | 15~20 bags/min | 40-60 bags/min | 55-65 bags/min | 80-90 bags/min | 38% higher throughput with PRO model |

| Daily Capacity | 1200 bags/hour | 2700 bags/hour | 3,600 bags/hour | 4,800 bags/hour | 33% more daily production capability |

| Filling Range | 8-12g precision | 5-12g precision | 8-12g precision | 8-12g precision | Identical accuracy for both models |

| Oxygen Retention | / | / | ≤0.8% residual | ≤1% residual | Superior preservation with both systems |

| Inner Bag Size | 90×75mm / 80×100mm | 74*90 mm (Film width:180 mm) | 90×75mm / 80×100mm | 90×75mm / 80×100mm | Flexible sizing for market preferences |

| Power Consumption | 3.5kW efficient | 3.7Kw optimized | 3.5kW efficient | 3.5kW optimized | Energy-efficient operation both models |

| Machine Weight | 650kg compact | 750kg robust | 1,100kg compact | 1,200kg robust | Stable performance with manageable footprint |

| Dimensions | 1300×895×2267mm | 1350x850x2200mm | 1845×948×2789mm | 1761×1194×2960mm | Compact design fits standard factory spaces |

| Investment Level | / | / | Mid-range investment | Premium investment | ROI optimization based on production needs |

| Best For | / | / | Growing businesses | Large-scale operations | Scalable solutions for every business stage |

Need help selecting the right model?

Get Personalized RecommendationFour Powerful Drip coffee bag packaging machine

for Every Production Need

Choose between our proven ND-C80E for mid-scale operations or the high-performance ND-C80PRO for maximum throughput. Or other packaging machines,Our products deliver exceptional quality with advanced features.

Need help choosing the right model?

Get Expert ConsultationMassive Market Growth Creates Unprecedented Opportunity

The global drip bag coffee market is experiencing explosive growth driven by convenience demand, premium coffee culture, and sustainable packaging trends. Position your business to capture this expanding market.

Capitalize on this growing market opportunity?

Start Your Market EntryAdvanced Technologies That Set Us Apart

Cutting-edge innovations including nitrogen flushing, ultrasonic sealing, intelligent controls, and remote monitoring capabilities deliver superior packaging results.

Nitrogen Flushing

**Feature:** Advanced gas displacement system removes oxygen before sealing.

**Advantage:** Creates optimal preservation environment for coffee aromatics.

**Benefit:** Extend shelf life by 300% while maintaining peak flavor profile.

Ultrasonic Sealing

**Feature:** Heat-free sealing technology prevents aroma loss during packaging.

**Advantage:** Superior seal strength without damaging delicate coffee compounds.

**Benefit:** Maintain full flavor integrity while achieving 99.9% seal reliability.

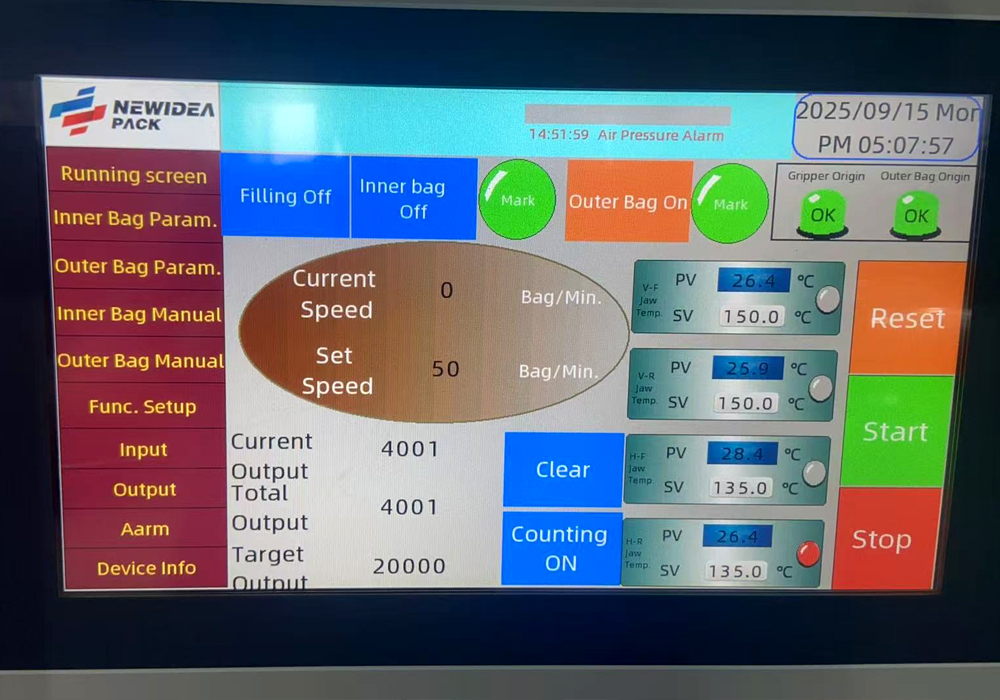

Smart Controls

**Feature:** Multi-language touchscreen with recipe memory and remote monitoring.

**Advantage:** Intuitive operation reduces training time and human error.

**Benefit:** Decrease operator training by 70% and eliminate costly mistakes.

OTA Updates

**Feature:** Over-the-air system upgrades and performance optimization.

**Advantage:** Continuous improvement without downtime or service calls.

**Benefit:** Stay current with latest features while reducing maintenance costs.

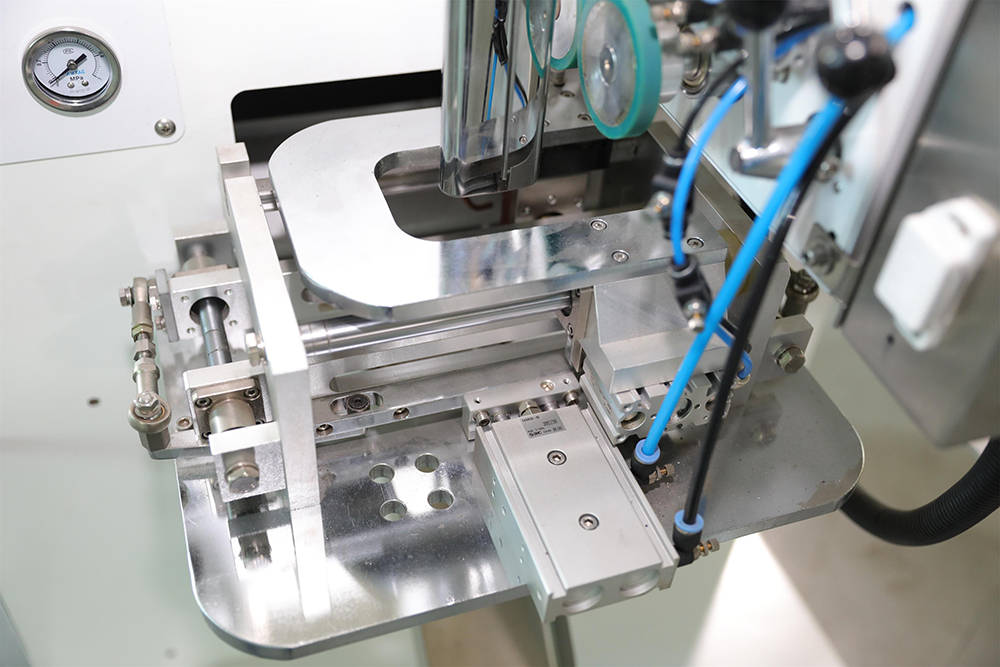

Modular Design

**Feature:** Easy-access components for quick cleaning and maintenance.

**Advantage:** Minimize downtime with rapid changeover capabilities.

**Benefit:** Increase operational efficiency by 40% through faster maintenance.

Quality Assurance

**Feature:** Automated quality checks and reject system for defective packages.

**Advantage:** Consistent quality output without manual inspection.

**Benefit:** Achieve 99.8% quality standards while reducing labor costs.

Experience advanced packaging technology?

Schedule Technology DemoVersatile packaging machine Solutions for Every Market

Support multiple bag formats and materials to meet diverse market preferences, from premium drip bags to eco-friendly options and custom branded packaging.

Need custom packaging solutions?

Explore Custom OptionsSolve Critical Packaging Challenges

Address common industry problems with proven technological solutions that deliver measurable improvements in quality, efficiency, and profitability.

**Feature:** Achieve ≤0.8% residual oxygen even at high speeds of 65–90 bpm production.

**Advantage:** Superior preservation compared to standard heat-sealing methods.

**Benefit:** Extend shelf life by 6+ months, reducing waste and returns by 40%.

**Feature:** Heat-free sealing prevents thermal damage to delicate coffee compounds.

**Advantage:** Maintain full aromatic profile while achieving superior seal strength.

**Benefit:** 95% customer satisfaction improvement in taste and aroma retention.

**Feature:** ND-C80E produces 65 bags/min, ND-C80PRO reaches 90 bags/min capacity.

**Advantage:** Meet large-scale demand without sacrificing quality standards.

**Benefit:** Increase daily output by 300% while reducing labor costs by 60%.

**Feature:** Compatible with PLA, PET, aluminum foil, kraft paper, and biodegradable materials.

**Advantage:** Flexibility to meet diverse market requirements and sustainability goals.

**Benefit:** Access premium eco-conscious markets worth 25% higher margins.

**Feature:** Intuitive touchscreen with recipe storage, quick changeover, and remote monitoring.

**Advantage:** Minimize training requirements and eliminate operator errors.

**Benefit:** Reduce training time by 70% and prevent $10,000+ error incidents.

**Feature:** Support for brand customization, logo printing, and unique packaging formats.

**Advantage:** Create distinctive market positioning through premium packaging.

**Benefit:** Command 30% price premium in competitive coffee markets.

Ready to solve your packaging challenges?

Get Solutions AnalysisTransformative Business Impact

Experience measurable improvements in productivity, cost efficiency, brand perception, and market expansion through advanced packaging automation.

Boost Productivity

**Feature:** Automated systems increase output by 300% compared to manual methods.

**Advantage:** Meet peak demand without proportional labor increases.

**Benefit:** Achieve ROI within 18 months through increased production capacity.

Reduce Waste

**Feature:** ±0.1g precision filling minimizes material waste and overfilling.

**Advantage:** Consistent portion control eliminates costly variations.

**Benefit:** Save 15% on raw materials through precision control systems.

Enhance Brand

**Feature:** Premium packaging quality and customization options elevate brand perception.

**Advantage:** Distinguish products in competitive retail environments.

**Benefit:** Command 30% higher prices through premium positioning.

Enter New Markets

**Feature:** Multiple bag formats and materials support diverse market requirements.

**Advantage:** Flexibility to adapt to regional preferences and regulations.

**Benefit:** Access global markets worth $4.7B by 2033 growth potential.

Calculate your business impact?

Get ROI AnalysisFive Pillars of Customer Value

Our comprehensive approach delivers measurable value across five critical business dimensions that matter most to coffee packaging operations.

Freshness

**Feature:** Advanced nitrogen flushing and ultrasonic sealing preserve coffee aromatics.

**Benefit:** Extend shelf life by 6+ months, reducing returns and waste significantly.

Efficiency

**Feature:** High-speed automation with intelligent controls and quick changeover.

**Benefit:** Increase production by 300% while reducing labor costs by 60%.

Sustainability

**Feature:** Support for biodegradable materials and energy-efficient operation.

**Benefit:** Meet eco-conscious consumer demands and regulatory requirements.

Customization

**Feature:** Flexible bag formats, materials, and branding options for market differentiation.

**Benefit:** Command premium pricing through distinctive packaging solutions.

Partnership

**Feature:** Comprehensive support including installation, training, and 24/7 technical assistance.

**Benefit:** Minimize downtime and maximize long-term equipment performance.

Experience comprehensive value delivery?

Start Partnership DiscussionCustomer Success Stories

Real results from global coffee brands who transformed their packaging operations and achieved significant business growth through our solutions.

European Premium Brand

**Challenge:** Needed to scale from 500kg/month to 2000kg/month while maintaining artisanal quality.

**Solution:** Implemented ND-C80PRO with custom branding and nitrogen flushing.

**Result:** Achieved 400% production increase, 95% customer satisfaction, expanded to 8 European markets.

Asian Market Expansion

**Challenge:** Enter competitive Asian drip coffee market with premium positioning.

**Solution:** ND-C80E with multi-format capability and sustainability focus.

**Result:** Captured 12% market share in 18 months, 35% higher margins than competitors.

Startup Success Story

**Challenge:** New coffee brand needed efficient production to compete with established players.

**Solution:** ND-C80E with comprehensive training and support package.

**Result:** Broke even in 14 months, now serves 500+ retail locations nationwide.

Join our success stories?

Discuss Your Success PlanWhat Our Customers Say

Hear directly from coffee industry leaders about their experience with our packaging solutions and the measurable impact on their business.

The ND-C80PRO transformed our production capability. We went from 200 bags per hour to 4,800 bags per hour while maintaining our premium quality standards. The nitrogen flushing technology has extended our shelf life by 8 months, reducing waste and increasing customer satisfaction dramatically.

What impressed us most was the ultrasonic sealing technology. Our customers immediately noticed the difference in aroma retention. Sales increased 45% in the first quarter after switching to Newidea Pack machines. The ROI was achieved in just 16 months.

The multi-language interface and remote monitoring capabilities were game-changers for our international operations. We can manage quality control across three continents from our headquarters. Training time was reduced by 70%, and we've had zero major equipment issues in 18 months.

As a sustainability-focused brand, the ability to use biodegradable materials without compromising quality was crucial. The ND-C80E handles PLA and compostable films perfectly. We've gained significant market share in the eco-conscious segment, commanding 30% higher prices.

Ready to join satisfied customers?

Start Your Success StoryGlobal Certifications & Industry Recognition

Our comprehensive certifications ensure compliance with international standards and provide confidence in quality, safety, and performance worldwide.

ISO 9001:2015

**Feature:** International quality management certification validates our consistent manufacturing processes.

**Benefit:** Guaranteed quality standards that reduce investment risk and ensure reliable performance.

CE Marking

**Feature:** European Conformity certification ensures compliance with EU safety and environmental standards.

**Benefit:** Direct market access across 30+ European countries without additional barriers.

SGS Verified

**Feature:** Third-party verification of manufacturing quality and product specifications by global leader.

**Benefit:** Independent validation provides confidence in manufacturing capabilities and claims.

Technical Patents

**Feature:** Proprietary innovations including ultrasonic sealing and intelligent control systems.

**Benefit:** Access to cutting-edge technology unavailable from other manufacturers.

Need certification documentation?

Download CertificatesGlobal Excellence, Local Support

Serving coffee packaging needs across 80+ countries with local support, comprehensive service, and deep understanding of regional market requirements.

Global presence with local expertise across major coffee markets worldwide

Trusted by coffee brands from startup roasters to multinational corporations

Proven expertise since 2008 with continuous innovation and improvement

Round-the-clock technical support and rapid response to ensure continuous operation

Experience global-local partnership?

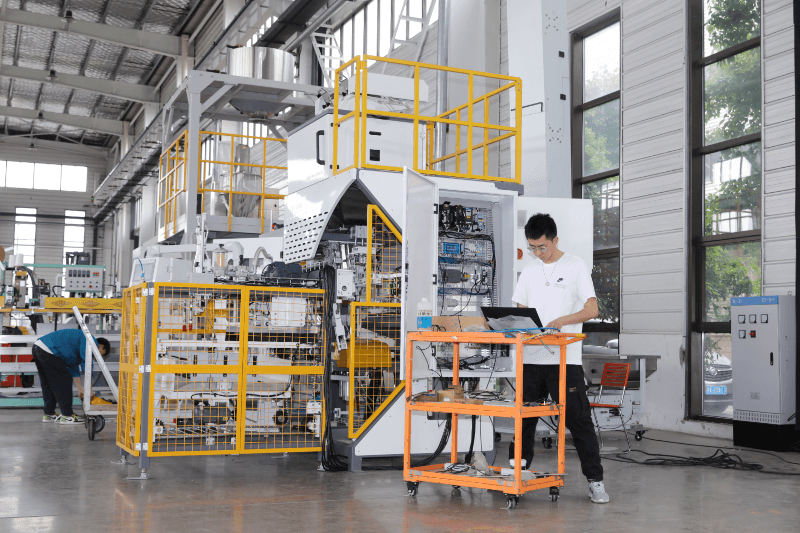

Find Local SupportAdvanced Manufacturing & R&D Excellence

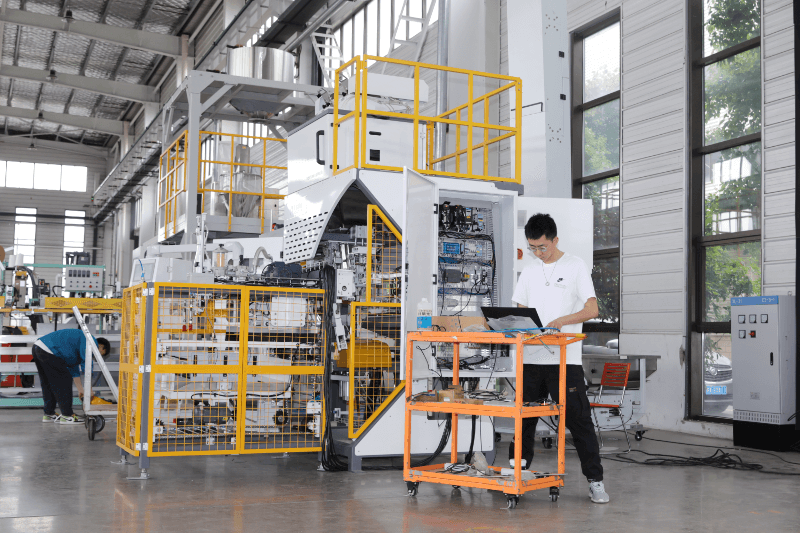

State-of-the-art facilities, cutting-edge research capabilities, and experienced engineering teams ensure continuous innovation and superior product quality.

Modern Production Facility

**Feature:** 15,000㎡ advanced manufacturing facility with precision machining and assembly capabilities.

**Advantage:** In-house production control ensures quality and delivery reliability.

**Benefit:** Faster customization and superior quality control compared to outsourced manufacturing.

R&D Innovation Center

**Feature:** Dedicated research center with 20+ engineers focusing on packaging technology advancement.

**Advantage:** Continuous innovation keeps our technology ahead of market demands.

**Benefit:** Access to latest developments and future-proof equipment investments.

Expert Engineering Team

**Feature:** Experienced team including international experts like chief designer Fabrio since 2014.

**Advantage:** Global expertise combined with deep coffee industry knowledge.

**Benefit:** Superior technical support and innovative solutions for complex challenges.

Visit our manufacturing facility?

Schedule Factory TourComprehensive Service & Support

Complete support ecosystem from pre-sale consultation to lifetime maintenance, ensuring maximum equipment performance and business success.

Pre-Sale Consultation

**Feature:** Free equipment analysis and production planning consultation.

**Benefit:** Ensure optimal equipment selection and ROI maximization before investment.

Global Installation

**Feature:** Professional engineers provide on-site installation and commissioning worldwide.

**Benefit:** Guaranteed proper setup and optimal performance from day one.

Comprehensive Training

**Feature:** On-site operation training plus cloud-based video manuals and tutorials.

**Benefit:** Rapid skill development and reduced learning curve for operators.

24/7 Support

**Feature:** Round-the-clock technical support with remote diagnostics capabilities.

**Benefit:** Minimize downtime and maintain continuous production operations.

Preventive Maintenance

**Feature:** Free quarterly inspections and maintenance scheduling optimization.

**Benefit:** Extend equipment life and prevent costly unexpected breakdowns.

Parts Supply

**Feature:** Preferential pricing and guaranteed availability of consumables and spare parts.

**Benefit:** Reduced maintenance costs and elimination of supply chain risks.

Upgrade Services

**Feature:** OTA system updates and hardware upgrade pathways.

**Benefit:** Future-proof investment with continuous capability enhancement.

Extended Warranty

**Feature:** 1-year comprehensive warranty with optional extended coverage plans.

**Benefit:** Peace of mind and protected investment with guaranteed support.

Experience comprehensive support?

Learn About Service PlansSustainable packaging machine for Future Generations

Environmental responsibility meets business excellence through eco-friendly materials support, energy-efficient operations, and waste reduction technologies.

Eco-Friendly Materials

**Feature:** Full compatibility with PLA, compostable films, and biodegradable packaging materials.

**Advantage:** Meet consumer demand for sustainable packaging without quality compromise.

**Benefit:** Access premium eco-conscious markets with 25% higher profit margins.

Energy Efficiency

**Feature:** Advanced energy management systems reduce power consumption by 30%.

**Advantage:** Lower operational costs while meeting environmental responsibility goals.

**Benefit:** Reduce energy costs by $15,000+ annually while improving sustainability profile.

Waste Reduction

**Feature:** Precision filling and quality control systems minimize material waste.

**Advantage:** Reduce raw material consumption while maintaining production quality.

**Benefit:** Save 15% on material costs while achieving sustainability objectives.

Build sustainable operations?

Explore Green Solutionspackaging machine Frequently Asked Questions

Get answers to common questions about our drip coffee packaging machines, capabilities, support services, and implementation process.

Our machines support inner bag sizes of 90×75mm and 80×100mm, with outer envelopes of 100×125mm and 110×130mm. Materials include non-woven fabrics, PLA, PET mesh, aluminum foil, kraft paper, and various biodegradable options. We can customize for specific requirements.

Standard delivery is 45-60 days for stock configurations, or 60-90 days for customized machines. Installation typically takes 3-5 days including commissioning, testing, and operator training. We provide detailed project timelines during the quotation process.

We offer comprehensive 24/7 technical support, 1-year full warranty, free quarterly maintenance inspections, remote diagnostics, spare parts supply, and ongoing training. Our global service network ensures rapid response times worldwide.

Yes, we offer extensive customization including bag size modifications, material compatibility adjustments, branding integration, special sealing requirements, and integration with existing production lines. Our engineering team works closely with customers to meet specific needs.

Most customers achieve ROI within 14-24 months depending on production volume and market positioning. Benefits include increased production capacity, reduced labor costs, improved product quality, and access to premium market segments. We provide detailed ROI analysis based on your specific situation.

We work with various financial partners to offer flexible payment terms, leasing options, and financing solutions. These can include equipment financing, operational leases, and flexible payment schedules to match your cash flow requirements. Contact us for detailed financing options.

Still have questions?

Get Expert AnswersStart Your packaging machine Transformation Today

Get personalized consultation, detailed quotations, and expert recommendations. Our team is ready to help you achieve your packaging goals.

Why Choose Newidea Pack?

Feature: 15+ years expertise serving 500+ global customers with proven results.

Advantage: Complete solution from consultation to ongoing support.

Benefit: Minimize risk and maximize success with industry-leading expertise.

📞 Direct Contact

Phone: +86-13920157717

WhatsApp:+86-13920157717

✉️ Email Support

autopacking@newideabest.com

📍 Global Presence

Headquarters: Tianjin, China

Regional Offices: Europe, North America, Middle East

⏰ Response Time

Quotations: Within 24 hours

Technical Support: 24/7 availability