Automatic Robot Palletizing Application In Big Bag Packaging

We are in an era of fierce competition, especially the rapid development of high-tech industries. Whoever uses high technology to solve problems will be able to get ahead faster. The application of robot palletizing is an example.Automatic robot palletizing system is widely used in 20-50kg bag palletizing, box palletizing, box palletizing, pallet palletizing and so on. Helped many large enterprises to achieve rapid development. Today, I will mainly talk about the application of the fully automatic robot palletizing system in 20-50kg big bag packaging.20-50kg bags are generally used to pack rice, beans, sugar, salt, feed, fertilizers and other products.

So what are the advantages of using automatic robot palletizing for 20-50kg big bags?

- Simple structure and few parts. Therefore, the failure rate of the parts is low, the performance is reliable, the maintenance is simple, and the required stock parts are few.

- Simple operation and strong adaptability. When the size, volume, shape of the customer’s product and the outer dimension of the pallet change, only a slight modification on the touch screen is required, which will not affect the customer’s normal production.

- The small area is conducive to the layout of the production line in the customer’s factory, and a larger warehouse area can be reserved to save the cost of the factory.

- Save a lot of labor, reduce labor mobility and the difficulty of recruiting workers to cause production instability to the enterprise.

- Improve product quality and consistency, realize product standardization, reduce material waste and increase output.

- Improve production efficiency and quickly complete order tasks without backlogging inventory.

- Improve the work quality of employees and make the working environment safer.

How to connect the automatic robot palletizing with the 20-50kg big bag packaging machine and subsequent processes? It requires some auxiliary equipment to complete.

1.Knock Bag down device and climbing conveyor for automatic robot palletizing

After 20-50kg semi-automatic or fully automatic packaging machine packaging and sealing (plus 2 product links), the bag needs to be adjusted from an upright state to a flat state. This requires a bag inverting mechanism, which can be implemented in multiple ways and customized according to different schemes. After the bag becomes flat, it will fall on the climbing conveyor belt and be transported to the back platform.

2.Weight checker, metal checker and rejection conveyor

After the bag is laid flat, if weight detection and metal detection are required, these two devices can be used, and then the unqualified products are rejected by the device and pushed out. The acceptable range of product weight can be set through reinspection, too much or too little weight will be rejected. For food and feed products, the presence of heavy metals can be detected through metal detection to ensure product safety.

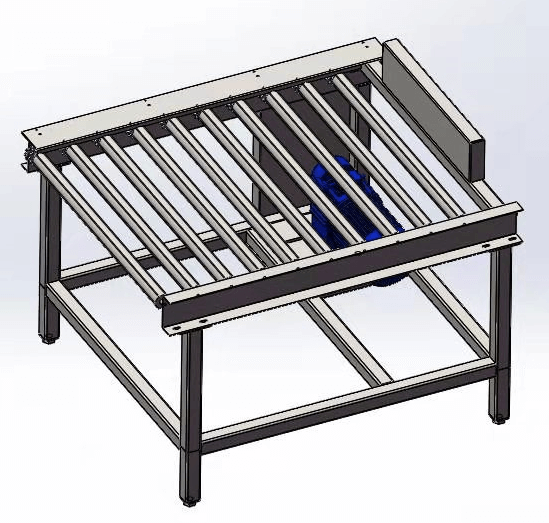

3.Flatting conveyor

In order to make the robot stacking more smoothly and neatly, the bags need to be flattened. This requires a conveyor belt. Usually the conveyor belt adopts a square roller conveyor belt. When the bag passes through, there will be a large roller or double-layer conveyor belt above, so that the material is evenly distributed and the bag is flat.

If you do not have the need for weight and metal detection in the automatic robot palletizing line, the climbing conveyor can be directly connected to the shaping conveyor belt.

4.The robot gripping position conveyor

After the shaping machine, the finished bags will be transported to another conveyor , located below the robot gripper, usually a steel pipe conveyor. After the robot gripper receives the signal, it will grab the bag to the pallet.

5.Empty pallet conveyor

This conveyor is used for empty pallet.The robot gripper puts the finished bags on the pallet. This requires the palletizing method to be set in the robot program in advance. Different palletizing methods can be changed, which is very simple and convenient.

6.Pallet library for automatic robot palletizing

It is used to store empty pallets, generally 10 can be stored. After the previous empty pallets are full, the pallet library will automatically release a pallet to the empty pallet conveyor belt for the next palletizing.

7.Automatic film wrapping machine

After the palletizing is completed, the tray is automatically transported to the film wrapping machine, and the film wrapping machine automatically wraps the film after receiving the signal.

8.Output conveyor after wrapping

The wrapped pallets will be transported to the next conveyor. At this time, workers can use forklifts to transport the finished pallets to the warehouse.

You can find that in the entire process of automatic robot palletizing , it is completely automated machine control, without human involvement. Now I think you understand why the robot palletizing system has so many advantages. This is just one of the connection methods, and there are different methods specific to the customer’s situation. For related customer cases, please refer to animal feed packaging line.

Tianjin Newidea Machinery Co., Ltd, has abundantf experience in automatic robot palletizing solutions, and uses the ABB robotic system. It is a leading supplier of industrial robots in handling, assembly, picking, packaging and palletizing tasks. If you are looking for a supplier of 20-50kg bag packaging machine and fully automatic robotic palletizing system, please contact us. Our professional team can discuss your ideas and formulate perfect automatic robot palletizing solutions with you.