What Innovative Leaders Know About Successful Inner And Outer Bag Packaging

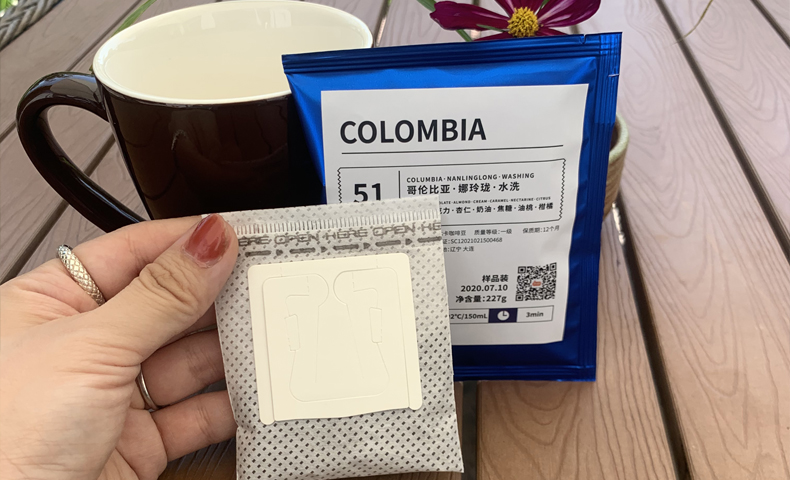

You have likely experienced the frustration of watching your production line grind to a halt because the inner bag missed its mark, leading to wasted coffee and ruined materials. It is a nightmare for ROI and brand reputation when thousands of pouches end up in the scrap bin due to poor alignment or failed seals. The solution lies in the millisecond-level synchronization of inner and outer bag packaging technology, which turns a complex multi-step process into a seamless, high-speed flow.

How does inner and outer bag packaging achieve synchronization?

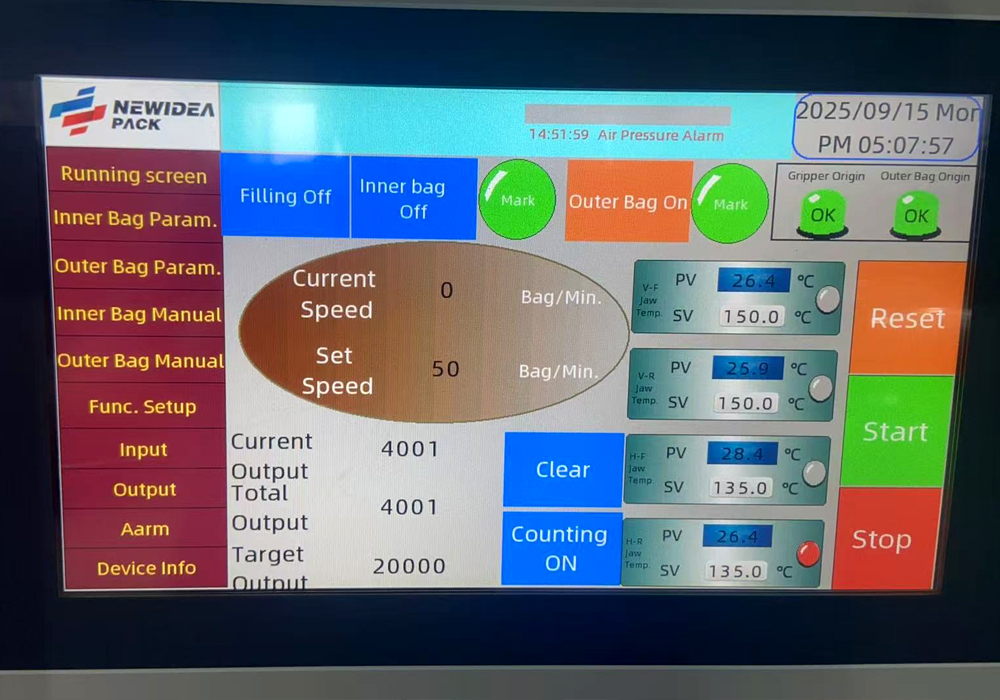

Inner and outer bag packaging achieves perfect synchronization by using electronic gears managed by a central PLC to match the speed of the inner bag creation with the outer envelope feeding. This digital handshake ensures that the non-woven filter bag is ready to be inserted the exact moment the outer film forms a pocket. By utilizing inner and outer bag packaging technology from Newidea Pack, roasters can finally achieve the high speeds necessary for global distribution.

What is the dual servo advantage?

You might be wondering why mechanical chains are no longer enough for modern production.

- Precision Control: Servos adjust speeds in increments of 0.01mm.

- Dynamic Correction: If the film slips, the system corrects it instantly.

- Reduced Wear: Fewer moving parts mean less mechanical fatigue.

But here is the kicker: this technology allows for speeds exceeding 60 bags per minute.

Why does film alignment matter?

Proper alignment is the difference between a premium product and a pile of scrap.

- It prevents the inner bag from being caught in the outer seal.

- It ensures the “tear here” notch is perfectly placed every time.

- It maintains the visual integrity of your brand’s printed artwork.

| Component | Function | Benefit |

|---|---|---|

| PLC Controller | Logic processing | Millisecond response |

| Servo Motor | Motion control | Zero-slip positioning |

| Photoelectric Sensor | Mark detection | Precise cutting |

The integration of these components ensures that your production line remains consistent even during high-velocity shifts.

Key Takeaway: Electronic synchronization via dual servos eliminates the mechanical lag that causes waste in traditional drip coffee setups.

Why is timing critical for inner and outer bag packaging?

Timing is the defining factor in inner and outer bag packaging because the insertion of the filter into the envelope occurs within a window of less than 100 milliseconds. If the outer bag closes too early, the inner bag is crushed; if it closes too late, the nitrogen flush is lost and the seal becomes compromised. Our ND-C80PRO Automatic Drip Coffee Bag Packaging Machine utilizes high-speed encoders to monitor these positions thousands of times per second.

Can timing prevent empty bags?

Empty bags are a silent profit killer in high-volume coffee operations.

- The machine detects if coffee dosing was successful before forming the outer.

- If no inner bag is detected, the outer film feed is paused.

- This prevents the waste of expensive composite outer films.

This is exactly what you need to keep your reject bin empty.

How do encoders assist timing?

Have you ever considered how a machine “knows” exactly where a bag is located?

- Encoders track the rotational position of the drive shaft.

- This data is fed back to the servos to adjust the film tension.

- It allows for real-time micro-adjustments without stopping the line.

| Event | Required Accuracy | System Response |

|---|---|---|

| Inner Insertion | <15ms | Servo acceleration |

| Outer Sealing | <10ms | Heat dwell control |

| Cutting | <5ms | Knife stroke sync |

Reliable timing ensures that every bag coming off the conveyor is a perfect representation of your brand.

Key Takeaway: High-speed timing accuracy prevents the common issue of “half-seals” where the filter is accidentally caught in the envelope’s thermal seal.

Does ultrasonic sealing improve inner and outer bag packaging?

Ultrasonic sealing improves inner and outer bag packaging by providing a “cold” seal that prevents the non-woven filter from melting or adhering to the outer envelope. Unlike traditional heat bars, ultrasonic waves create friction only at the contact points of the fabric, which preserves the structural integrity of the filter ears. This is essential for ensuring that when your customer opens the bag, the hanging ears don’t tear or stick to the packaging.

Why is heat-free sealing better?

Think about how high temperatures can affect delicate coffee oils and aromas.

- Aroma Preservation: No residual heat means no scorched coffee smell.

- Seal Strength: Ultrasonic welds are often stronger than the material itself.

- Safety: The sealing horns remain cool to the touch.

As it turns out, this is the gold standard for specialty coffee.

Does it speed up production?

You probably want to know if this tech slows you down, but the opposite is true.

- Ultrasonic sealing requires no “warm-up” time for the machine.

- The cooling phase is instantaneous, allowing for faster bag discharge.

- It reduces the energy consumption of the overall drip-bag ultrasonic packaging machine system.

| Feature | Ultrasonic Sealing | Traditional Heat Seal |

|---|---|---|

| Thermal Impact | Zero | High |

| Material Compatibility | Non-woven / PLA | Limited to plastics |

| Seal Reliability | 99.9% | Variable with temp |

Choosing ultrasonic sealing is an investment in the sensory experience your customers have with your coffee.

Key Takeaway: Ultrasonic technology ensures the inner filter remains pristine while allowing for the fastest possible cycle times in the industry.

How can dual servo systems optimize inner and outer bag packaging?

Dual servo systems optimize inner and outer bag packaging by decoupling the material feed from the sealing cycle, allowing each to be adjusted independently for different film types. If you switch from a standard plastic outer to a sustainable paper-based composite, the servo system can automatically compensate for the different tension requirements. This flexibility allows Newidea Pack customers to pivot between different product lines without hours of mechanical re-tooling.

What does decoupling mean?

In older machines, everything was connected to one big motor and a chain.

- If you slowed the sealer, the film feed slowed too.

- Now, you can run the film fast but seal for longer.

- This provides better control over complex laminate structures.

This is a total game-changer for thick barrier films.

Can you adjust bag length?

The short answer is: yes, and it is easier than you think.

- You enter the desired length on the HMI touchscreen.

- The servo automatically calculates the necessary feed rate.

- This eliminates the need for manual gear changes.

| Optimization | Method | Result |

|---|---|---|

| Tension Control | Load-cell feedback | Zero film breakage |

| Speed Ramp | S-curve acceleration | Smooth bag handling |

| Size Change | Recipe storage | 2-minute changeovers |

Advanced motion control turns a rigid mechanical process into a programmable, highly efficient asset.

Key Takeaway: Dual servo systems provide the digital agility needed to handle various materials and sizes without manual hardware changes.

Can inner and outer bag packaging reduce material waste?

Inner and outer bag packaging reduces material waste through the use of high-resolution registration sensors that detect inner and outer bag packaging misalignments before the cutting phase. By identifying a drift in the film position early, the machine can make micro-adjustments to the servo speed, preventing a single bad seal from turning into a hundred wasted bags. For expensive specialty coffee, this reduction in waste directly translates to higher profit margins.

How do sensors prevent errors?

Imagine having a supervisor watching every single millimetre of your production line.

- Eye Mark Tracking: Sensors find the printed mark on the film.

- Auto-Stop: If the film runs out or breaks, the machine stops instantly.

- Auto-Reject: Defective bags are removed without stopping the entire line.

It’s like having an insurance policy for your raw materials.

Is coffee waste also reduced?

You might be worried about spilling grounds during the high-speed transfer.

- Precision dosing heads only fire when the inner bag is open.

- Anti-static bars prevent grounds from clinging to the seal area.

- Vacuum suction ensures the bag mouth is perfectly aligned for the funnel.

| Waste Type | Cause | Prevention Method |

|---|---|---|

| Film Scrap | Misalignment | Photoelectric tracking |

| Coffee Spillage | Timing errors | No-bag-no-fill logic |

| Rejects | Weak seals | Ultrasonic monitoring |

Minimizing waste is not just about sustainability; it is about maximizing your bottom line every single day.

Key Takeaway: Real-time sensor feedback and anti-static measures ensure that every gram of coffee and every centimeter of film is utilized effectively.

What film types work best for inner and outer bag packaging?

Inner and outer bag packaging works best with a combination of non-woven fabrics for the filter and high-barrier aluminum or PET/PE laminates for the outer envelope. The inner bag must provide high permeability for water flow while the outer bag must act as a complete barrier against oxygen and moisture. Selecting the right materials ensures that the synchronization system can grip and pull the film consistently without stretching or slipping.

Why use non-woven for filters?

You need a material that is food-grade and won’t impart flavor.

- It withstands boiling water without breaking.

- It allows for the precise ultrasonic welding of the “ears.”

- It is compatible with sustainable PLA fibers for eco-conscious brands.

But most importantly, it offers the perfect flow rate for drip coffee.

What makes a good outer film?

Does your coffee need to stay fresh for a year on a supermarket shelf?

- AL/PE Laminates: The gold standard for oxygen barriers.

- Matte Finishes: Provides a premium feel for high-end brands.

- Composites: Ensure the synchronization system can track the eye-marks accurately.

| Bag Layer | Material Recommendation | Primary Benefit |

|---|---|---|

| Inner | Non-woven / PLA | Neutral taste & strength |

| Outer | PET/AL/PE | Maximum aroma barrier |

| Sealant | Low-temp PE | Fast sealing speeds |

Matching your machinery to the right film specifications is the secret to a professional, shelf-ready product.

Key Takeaway: Using compatible, high-quality films reduces friction and static, which keeps the synchronization system running smoothly at top speeds.

How does nitrogen flushing affect inner and outer bag packaging?

Nitrogen flushing affects inner and outer bag packaging by requiring a sealed environment where oxygen is displaced just before the final outer bag closure. To maintain a residual oxygen level of less than 1%, the synchronization between the nitrogen injection nozzle and the outer bag sealing bars must be perfect. If the timing is off even slightly, oxygen will seep back into the envelope, causing the coffee oils to oxidize and turn rancid.

How is nitrogen injected?

The process happens in a split second, but it is highly controlled.

- A nozzle descends into the outer bag as the inner is inserted.

- A high-pressure burst of N2 displaces the ambient air.

- Oxygen sensors monitor the levels in real-time.

This ensures your coffee tastes as fresh in six months as it does today.

Does flushing affect the seal?

You might worry that the gas pressure will blow the bag open.

- Vacuum-suction holds the bag steady during the flush.

- The seal is applied immediately after the nozzle retracts.

- This creates the distinctive “pillowed” look of a fresh bag.

| Parameter | Targeted Level | Machine Requirement |

|---|---|---|

| Oxygen Residual | < 1.0% | Multi-point injection |

| Nitrogen Purity | > 99.9% | Reliable N2 generator |

| Gas Pressure | 0.2 – 0.4 Mpa | Constant flow valve |

Maintaining low oxygen levels is the most effective way to extend your product’s geographical reach.

Key Takeaway: Precise nitrogen flushing integrated with synchronized packaging preserves the delicate volatiles that define specialty coffee.

Is maintenance easier with modern inner and outer bag packaging?

Maintenance is significantly easier with modern inner and outer bag packaging because the shift from mechanical cams to digital servos allows for software-based troubleshooting. Instead of spending hours adjusting tension springs, operators can use the HMI (Human Machine Interface) to run diagnostics on each motor. Newidea Pack systems even include remote support capabilities, allowing engineers to calibrate your synchronization settings from across the globe.

Are there fewer moving parts?

Think about how much time you lose to mechanical breakdowns.

- Servos eliminate 60% of traditional drive belts and chains.

- Lubrication requirements are reduced by nearly half.

- Fewer parts mean a smaller spare parts inventory is required.

This means more “up-time” for your production facility.

How does the PLC help?

Have you ever spent a whole day trying to find a tiny timing error?

- The PLC logs every error code with a timestamp.

- It points you directly to the sensor or motor that is failing.

- It provides a drip coffee bag production guide on-screen for common tasks.

| Maintenance Task | Traditional Machine | Modern Servo Machine |

|---|---|---|

| Timing Adjustment | Manual gear shifting | Digital HMI input |

| Part Replacement | High (chains/cams) | Low (modular units) |

| Troubleshooting | Trial and error | Real-time error codes |

Simplified maintenance routines mean your staff can focus on coffee quality rather than mechanical repairs.

Key Takeaway: Digital diagnostics and modular components reduce the specialized knowledge required to keep your drip coffee line running at peak performance.

Can inner and outer bag packaging handle different bag sizes?

Inner and outer bag packaging can easily handle different bag sizes by utilizing “recipe” storage in the PLC, which automatically adjusts the stroke lengths for each format. Whether you are producing a standard 10g single-serve or a larger 12g “strong brew” version, the machine compensates by changing the film pull distance and the sealing dwell time. This versatility is vital for contract packers who serve multiple clients with varying brand standards and portion sizes.

Is the changeover process fast?

No one wants to lose four hours of production just to change a bag size.

- Tool-less changeovers allow for quick adjustments of forming tubes.

- Digital settings load in seconds at the touch of a button.

- It minimizes the downtime between different product batches.

It is as simple as selecting a new file on your computer.

Can it handle custom shapes?

You might want to stand out with a wider outer envelope.

- The outer bag width is determined by the forming shoulder.

- These shoulders are interchangeable for different widths.

- The synchronization system adapts to these physical changes automatically.

| Size Change | Component Adjusted | Time Required |

|---|---|---|

| Bag Length | Servo Parameters | < 1 minute |

| Bag Width | Forming Tube | 15 minutes |

| Dosing Volume | Auger/Volumetric | 5 minutes |

Versatility ensures that your equipment remains relevant even as your product lineup evolves.

Key Takeaway: Flexible machine architecture allows your business to scale and adapt to market trends without purchasing entirely new equipment.

Why choose Newidea Pack for inner and outer bag packaging?

Choosing Newidea Pack for inner and outer bag packaging guarantees you access to over 18 years of specialized engineering expertise in the drip coffee industry. Our machines are built with high-grade SUS304 stainless steel and utilize top-tier components from brands like Mitsubishi and SMC to ensure long-term reliability. We don’t just sell you a machine; we provide a fully integrated solution that includes installation, training, and 24/7 technical support to ensure your success.

What about technical support?

You need to know that someone has your back when things get complicated.

- We offer 2-hour response times for technical inquiries.

- Our global network ensures parts are available when you need them.

- We provide customized video tutorials for your specific machine setup.

This commitment to service is why international coffee leaders trust us.

Are the machines built to last?

Quality is not just a buzzword; it is a manufacturing standard.

- Every machine undergoes a 72-hour continuous run test before shipping.

- We hold numerous patents for our unique ultrasonic sealing designs.

- Our frames are designed for maximum vibration damping at high speeds.

| Benefit | Newidea Pack Standard | Industry Average |

|---|---|---|

| Production Speed | 80-90 bags/min | 40-50 bags/min |

| O2 Residual | < 1.0% | 2.0% – 3.0% |

| Machine Lifespan | 10+ Years | 5-7 Years |

Partnering with a specialist ensures your packaging line is a competitive advantage, not a bottleneck.

Key Takeaway: Newidea Pack delivers a combination of cutting-edge synchronization technology and robust construction that maximizes your production ROI.

Modernizing your drip coffee production is no longer an option—it is a necessity for survival in a competitive global market. By synchronizing your inner and outer bag packaging with dual-servo precision and ultrasonic sealing, you eliminate the waste and inconsistency that plague traditional setups. This analysis has detailed how these technologies work together to preserve aroma, extend shelf life, and maximize your output.

FAQ

Can I use the same machine for different coffee weights?

Yes, absolutely. Most Newidea Pack machines allow you to adjust the dosing range from 5g to 12g via the HMI touchscreen, provided you have the correct forming tube and auger size for your specific coffee density.

What is the best way to prevent the inner bag from sticking?

The best way is to utilize ultrasonic sealing. Since ultrasonic waves only generate heat at the weld point, the surrounding filter material remains cool, preventing it from adhering to the outer envelope film during the high-speed synchronization process.

How do I know if my synchronization timing is starting to fail?

You will usually notice “leakers” or crushed inner filters in your reject bin. Modern PLC systems will also trigger a timing alarm if the photoelectric sensors detect that the film’s eye marks are not lining up with the mechanical cycle within the allowed tolerance.

Can I pack tea in these drip bags as well?

Yes, you certainly can. These machines are highly versatile and can handle various types of tea leaves or herbal blends, though you may need to adjust the dosing system depending on the leaf size.

What’s the best material for the outer bag to ensure freshness?

The best material is usually a three-layer laminate, such as PET/AL/PE. This combination provides an absolute barrier against oxygen and moisture, which is essential when you are utilizing nitrogen flushing to achieve a long shelf life.

If you are ready to take your packaging speed to the next level and protect the integrity of your beans?

contact us today to discuss a custom solution. At Newidea Pack, we don’t just build machines; we engineer the future of fresh coffee.