Ultimate Guide to Safely Importing Packaging Machinery from China

Importing a packaging machine from China safely involves a structured process of supplier vetting, technical specification alignment, and rigorous quality inspection. By partnering with established manufacturers like newideapack, you can navigate the complexities of international trade and secure high-performance equipment that meets global standards.

Buying machinery from China can be a game-changer for your production line. However, the fear of receiving sub-par equipment or losing a significant investment keeps many business owners awake at night. You might worry about communication barriers or hidden costs that eat into your margins. Fortunately, following a professional procurement framework turns these risks into manageable steps, allowing you to access advanced technology at a fraction of the cost found in domestic markets. This guide will show you exactly how to import packaging machine units without the typical headaches.

Why should you import packaging machine from China now?

You should choose to import packaging machine units from China today because the region offers an unmatched balance of rapid technological innovation and manufacturing cost-efficiency. By sourcing directly, you bypass heavy local markups and gain access to the latest automation features that are often developed first in China’s massive industrial hubs.

Is Chinese technology advanced enough for you?

The short answer is a resounding yes. Modern Chinese manufacturers like newideapack utilize international components from brands like Siemens or SMC to ensure reliability.

- Precision engineering in ultrasonic sealing.

- High-speed PLC control systems.

- Modular designs for easy maintenance.

Think about it:

If the world’s biggest brands manufacture there, the infrastructure is ready for your needs too.

How much can you actually save?

Significant savings often range from 30% to 60% compared to European or American counterparts. These savings allow you to reinvest in better raw materials or marketing.

- Lower labor costs in production.

- Economies of scale in parts sourcing.

- Competitive pricing due to a high density of suppliers.

Here is the deal:

You aren’t just saving money; you are buying the capacity to scale your business faster than your competitors.

Key Takeaway: Importing from China provides a strategic competitive advantage through high-tech machinery at a significantly lower capital expenditure.

| Factor | Chinese Import | Domestic Purchase |

|---|---|---|

| Initial Cost | 40-60% Lower | Premium Pricing |

| Customization | Highly Flexible | Often Standardized |

| Lead Time | 30-60 Days | 15-30 Days |

The data shows that the cost-to-performance ratio remains the strongest driver for overseas procurement.

How to find a reliable import packaging machine supplier?

To find a reliable supplier, you must conduct deep due diligence by verifying business licenses, checking third-party audit reports, and reviewing their specialized experience. When you prepare to import packaging machine solutions, working with a factory that has a documented history, such as newideapack, ensures your investment is protected by professional standards.

What are the signs of a trustworthy factory?

Look for companies that provide clear documentation and have a transparent manufacturing process. A real manufacturer will always be happy to show you their workshop via a live video call.

- Valid ISO and CE certifications.

- Verified Gold Supplier status on major B2B platforms.

- Specific expertise in your niche (e.g., coffee or powder).

But wait, there’s more.

A reliable supplier will ask you more questions about your product than you ask them, ensuring the machine fits your specific needs.

Should you use B2B platforms or trade shows?

Both have their merits, but trade shows allow for a “touch and feel” experience that digital platforms lack. However, digital platforms are excellent for initial broad research and comparing technical data sheets.

- Alibaba/Global Sources for initial vetting.

- Canton Fair for face-to-face negotiation.

- LinkedIn for checking company reputation and updates.

Look:

The best suppliers aren’t always the ones with the flashiest ads, but the ones with the most consistent technical feedback.

Key Takeaway: Thorough verification of a supplier’s manufacturing credentials and technical responsiveness is the only way to ensure a safe purchase.

| Verification Step | Purpose | Importance |

|---|---|---|

| License Check | Confirms legal existence | Essential |

| Factory Audit | Verifies production capacity | High |

| Client Reviews | Gauges long-term reliability | Moderate |

Establishing a foundation of trust through verification prevents 90% of common import mistakes.

What specs matter to import packaging machine safely?

The most critical specifications include voltage compatibility, material certifications for food safety, and the specific dimensions of your packaging film. To import packaging machine hardware successfully, you must ensure that every technical detail matches your local utility requirements and production environment before the machine leaves the factory floor.

Is your local voltage compatible?

You must confirm if your facility uses 110V, 220V, or 380V and if it is 50Hz or 60Hz. Failure to match these will lead to expensive electrical failures or the need for bulky transformers.

- Specify voltage during the quotation phase.

- Check the plug type for your region.

- Verify the motor and inverter ratings.

Think about it:

Small oversight in electrical specs can turn a high-tech machine into an expensive paperweight.

Which materials should you specify?

Always insist on high-grade stainless steel (SUS304 or SUS316) for all parts that come into contact with your product. This ensures compliance with health regulations and longevity of the equipment.

- Food-grade contact surfaces.

- High-quality pneumatic components.

- Durable heating elements for sealing.

The best part?

Specifying these high-quality materials upfront prevents rust and contamination issues down the line.

Key Takeaway: Detailed technical alignment on electrical and material specifications is the bridge between a machine that works and one that fails.

| Specification | User Requirement | Manufacturer Action |

|---|---|---|

| Power Supply | Must match local grid | Install correct motors |

| Contact Parts | Must be food-safe | Use SUS304/316 Steel |

| Seal Method | Must suit film type | Configure heaters/ultrasonic |

Precise specification acting as a blueprint ensures the final product meets your exact operational reality.

Can you import packaging machine without a middleman?

Yes, you can import directly from the manufacturer to save on commission costs and establish a direct line for technical support. When you import packaging machine units directly from newideapack, you eliminate the “telephone game” where technical requirements get lost in translation through various agents.

Why buy directly from the factory?

Buying direct gives you the lowest possible price and ensures that the engineers who built the machine are the ones helping you troubleshoot it. It also allows for much higher levels of customization for your specific packaging needs.

- Direct communication with technical teams.

- Zero hidden agent fees or markups.

- Faster response for spare parts.

Here is the deal:

Direct relationships build long-term value and ensure you get the most updated software and hardware versions.

How do you handle the language barrier?

Most reputable Chinese exporters employ professional English-speaking sales engineers who understand both the language and the technical nuances. You should use clear, bulleted emails and annotated photos to communicate complex ideas.

- Use WeChat for instant, translated communication.

- Share video demonstrations for clarity.

- Request all agreements in written English.

Look:

Visual communication transcends language, so always use photos and videos to explain your requirements.

Key Takeaway: Direct procurement fosters better technical understanding and significantly reduces the total cost of ownership.

| Channel | Cost | Technical Support | Communication |

|---|---|---|---|

| Factory Direct | Lowest | Direct/Expert | Fast/Technical |

| Trading Agent | Higher | Indirect | Simplified |

Eliminating intermediaries simplifies the supply chain and places you in control of the technical specs.

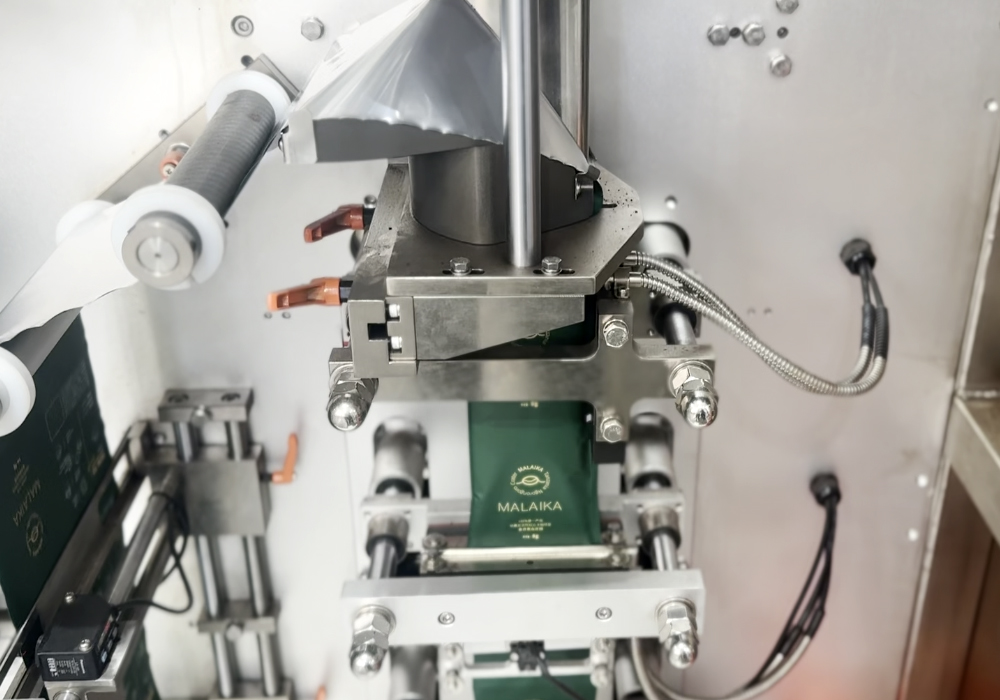

How to verify an import packaging machine via video?

You verify the machine by requesting a comprehensive Fat (Factory Acceptance Test) video that shows the machine running your specific product and film. Before you import packaging machine equipment, seeing it perform a continuous 30-minute run on video provides the visual proof needed to authorize the final payment.

What should the FAT video include?

The video must show the machine’s serial number, the date, and a clear view of the product being filled and sealed. You should also ask for a close-up of the control panel and the quality of the seals.

- Continuous operation for at least 20 minutes.

- Close-up of the sealing and cutting precision.

- Demonstration of the emergency stop and safety features.

Think about it:

A video is your best insurance policy before the machine is crated and shipped across the ocean.

Can you request a live demonstration?

Absolutely, and you should. A live video call allows you to ask the engineer to open specific panels or change settings in real-time to prove the machine’s flexibility.

- Use Zoom or WhatsApp for live tours.

- Ask to see the internal wiring and components.

- Verify the speed of the machine against the contract.

The best part?

Seeing the machine live builds the confidence you need to release the final 70% of the contract value.

Key Takeaway: Detailed video verification is a non-negotiable step that serves as your final quality checkpoint before shipping.

| Video Checkpoint | What to Look For | Result |

|---|---|---|

| Operation Speed | Bags per minute match | Verified Capacity |

| Seal Integrity | No leaks or wrinkles | Quality Assurance |

| Safety Sensors | Machine stops on door open | Operator Safety |

Visual evidence acts as a virtual inspection, bridging the gap between overseas manufacturing and local expectations.

What are the costs to import packaging machine units?

Beyond the machine price, you must budget for ocean freight, import duties, local port handling fees, and inland transportation. When planning to import packaging machine models like the newideapack ND-C80Pro, understanding the Total Landed Cost is essential for an accurate ROI calculation.

Hidden fees often include document fees, terminal handling charges (THC), and customs brokerage fees at your destination port. You should also account for marine insurance, which is a small but vital cost to protect your investment.

- Ocean freight (FOB vs. CIF).

- Customs bond and entry fees.

- Warehouse storage if clearance is delayed.

Look:

A $20,000 machine can easily cost $25,000 by the time it reaches your warehouse floor.

How do import duties affect your budget?

Import duties vary significantly by country and the specific HS code used for the machinery. You should consult a local customs broker to determine the exact percentage of tax you will owe upon arrival.

- Research the HS Code (usually 8422.40).

- Check for any anti-dumping duties.

- Factor in local VAT or sales tax.

But wait, there’s more.

Using the correct HS code is not just about compliance; it can sometimes save you thousands in unnecessary taxes.

Key Takeaway: Accurate budgeting for the “landed cost” prevents financial surprises and ensures your business plan remains viable.

| Cost Category | Estimated % of Machine Price | Note |

|---|---|---|

| Ocean Freight | 5% – 15% | Depends on container size |

| Import Duties | 0% – 10% | Varies by country/HS code |

| Local Delivery | 2% – 5% | Factory to your door |

Comprehensive cost mapping ensures that your “bargain” import remains a profitable investment after all expenses.

How to handle shipping for an import packaging machine?

The best way to handle shipping is to use a professional freight forwarder who specializes in heavy machinery and understands the requirements for wooden crate packaging. When you import packaging machine systems, ensuring the manufacturer uses IPPC-certified heat-treated pallets is mandatory for international customs compliance.

Should you choose FOB or CIF terms?

FOB (Free On Board) is generally recommended because it gives you control over the shipping costs and the choice of the forwarder at your end. CIF (Cost, Insurance, and Freight) is easier but often involves hidden “arrival fees” that the manufacturer might not disclose.

- FOB: You control the sea freight.

- CIF: The seller handles the logistics.

- DDP: The seller delivers to your door.

Think about it:

Controlling the logistics means you control the timeline and the final cost.

How is the machine protected during transit?

The machine should be sprayed with anti-rust oil, wrapped in vacuum-sealed plastic, and secured inside a robust plywood crate. This prevents salt-air corrosion and physical damage during the turbulent journey across the ocean.

- Vacuum packaging for moisture control.

- Internal bracing to prevent movement.

- Clear “Fragile” and “This Side Up” labeling.

The best part?

A well-packed machine can survive a rough sea voyage and arrive in “plug-and-play” condition.

Key Takeaway: Professional crating and a clear understanding of shipping terms are the final safeguards for your equipment’s physical integrity.

| Shipping Term | Buyer Responsibility | Seller Responsibility |

|---|---|---|

| FOB | Freight & Insurance | Loading at Port |

| CIF | Local Port Fees | Freight & Insurance |

| DDP | Nothing | Everything |

Choosing the right Incoterm balances your involvement level with your desire for cost control.

Does your import packaging machine meet local standards?

Your machine must comply with local safety and electrical standards, such as CE for Europe or UL/CSA for North America. When you import packaging machine solutions, newideapack ensures that the components used meet these rigorous global benchmarks for operator safety and operational reliability.

Is CE certification enough?

While CE is a global standard for safety, some regions or insurance companies may require specific local certifications. You should always verify with your local electrical inspector if additional labels or safety guards are required for your specific facility.

- CE for European markets.

- UL/CSA for USA and Canada.

- Appropriate safety guarding and E-stops.

Here is the deal:

Compliance isn’t just about legality; it’s about the safety of your employees and the longevity of your business.

How do you verify component quality?

Ask for a “Bill of Materials” (BOM) that lists the brands of the PLC, touch screen, and sensors. High-quality brands like Omron, Schneider, or Airtac are globally recognized and signify a machine built for long-term use.

- Request brand-name electronic components.

- Check for high-grade pneumatic valves.

- Ensure the software is in your native language.

Look:

A machine is only as strong as its weakest sensor, so don’t settle for generic electronic parts.

Key Takeaway: Prioritizing certified components and safety standards ensures your machine is legal to operate and safe for your staff.

| Standard | Region | Focus Area |

|---|---|---|

| CE | Europe | Safety & Environment |

| UL | North America | Electrical Safety |

| ISO 9001 | Global | Management Quality |

Adhering to international standards simplifies insurance and workplace safety audits in your home country.

How to install a new import packaging machine correctly?

Correct installation starts with a flat, stable floor and a clean compressed air supply that meets the machine’s CFM requirements. When you import packaging machine units, the manufacturer should provide a detailed installation video and a manual that guides you through the leveling and calibration process.

Can you install it yourself?

Many modern machines are designed for “self-installation,” but you should have a qualified electrician and a pneumatic technician on hand. Most issues during startup are caused by simple errors like reversed phases in power or inadequate air pressure.

- Check levelness with a precision tool.

- Verify all air lines are leak-free.

- Follow the startup sequence exactly.

Think about it:

Investing a few hours in a perfect setup saves weeks of troubleshooting later.

What if you need technical help?

Reliable manufacturers offer remote support via video calls where they can see your screen and guide your hands through the setup. You can also hire a local technician who can work under the remote guidance of the factory’s engineering team.

- Remote PLC troubleshooting via internet.

- Step-by-step video tutorials.

- 24/7 technical support hotlines.

The best part?

With modern communication, the factory engineer is essentially standing right next to you, regardless of the distance.

Key Takeaway: Proper preparation of your facility and utilizing remote technical support ensures a smooth transition from unboxing to full production.

| Installation Phase | Task | Requirement |

|---|---|---|

| Mechanical | Leveling the frame | Spirit Level |

| Electrical | Connecting power | Certified Electrician |

| Pneumatic | Connecting air supply | Dry, Clean Air |

A methodical installation process is the final step in securing your ROI from an overseas purchase.

Why is service vital for your import packaging machine?

After-sales service is vital because even the best machinery requires maintenance, and having a supplier that provides fast spare parts and technical advice is the only way to minimize downtime. When you import packaging machine hardware, the value of the purchase is determined more by the support you receive in year three than the price you paid in year one.

How do you get spare parts quickly?

A good manufacturer will include a “wear-parts kit” with the initial shipment, containing enough spares for the first year of operation. For everything else, ensure the supplier uses international couriers like DHL or FedEx for 3-5 day delivery of critical components.

- Insist on a free one-year spare parts kit.

- Verify that parts are standard and easy to source.

- Keep a small stock of critical sensors and heaters.

Look:

Downtime is the hidden killer of profits, so always have a backup plan for your most common wear items.

Does the manufacturer offer a warranty?

Standard industry warranties are 12 months for parts. You should clarify what the warranty covers and ensure that the manufacturer is willing to ship replacement parts at their expense if a failure occurs due to a manufacturing defect.

- 12-month standard warranty.

- Lifetime technical support.

- Clear replacement policy for defects.

Here is the deal:

A warranty is only as good as the company behind it, so choose a partner known for standing by their products.

Key Takeaway: Long-term success with an imported machine depends entirely on the quality of after-sales support and the availability of spare parts.

| Service Element | Standard Expectation | Excellence Mark |

|---|---|---|

| Response Time | Within 24 hours | Within 2 hours |

| Parts Delivery | 7-10 Days | 3-5 Days via DHL |

| Support Medium | Email/Manual | Live Video/Remote PLC |

Focusing on the service ecosystem ensures your machine remains a productive asset for the next decade.

Conclusion

Successfully buying machinery from overseas is a strategic journey that rewards those who prioritize verification over assumptions. By following the steps outlined—from selecting a reliable manufacturer like newideapack to conducting a rigorous Factory Acceptance Test—you can modernize your production line with confidence. We have solved the challenges of supplier vetting, technical alignment, and logistics, giving you a clear path to industrial growth.

If you are ready to upgrade your facility with world-class automation, contact us today to discuss your specific packaging requirements. Our mission is to bridge the gap between advanced manufacturing and your business success, ensuring every machine we deliver is a cornerstone of your future prosperity. At newideapack, we don’t just sell machines; we build the future of packaging together.

Frequently Asked Questions

Can I trust the quality of a Chinese packaging machine?

Yes, if you choose a verified manufacturer. Most high-quality machines use international components (Siemens, Omron) and undergo strict Factory Acceptance Tests before shipping.

What’s the best way to pay a Chinese supplier safely?

The most secure methods are via Letter of Credit (L/C) for large orders or through Trade Assurance on B2B platforms. Most factories use a 30% deposit and 70% balance after you approve the test video.

How do I know if the machine will fit my bags?

You should send samples of your actual film and product to the factory. They will test your materials on the machine and send you a video of the results to ensure 100% compatibility.

Can I get a technician to visit my factory for setup?

Yes, most manufacturers can send an engineer for on-site installation and training. However, due to travel costs, many buyers now prefer remote video installation which is faster and more cost-effective.

What happens if a part breaks after two years?

You can order spare parts directly from the manufacturer via express courier. Reputable companies like newideapack keep a digital record of your machine’s build to ensure the replacement parts match perfectly.

Are you ready to import packaging machinery from China?

If you are ready to upgrade your facility with world-class automation, contact us today to discuss your specific packaging requirements.