Nitrogen Flushing Secrets: How to Achieve <1% Residual Oxygen Levels

Are your customers complaining about stale coffee just weeks after purchase? Even a 2% oxygen level can ruin a premium roast. From the moment your beans are roasted, oxidation begins to degrade delicate oils and volatile aromatics, leading to a stale product within weeks. For B2B manufacturers, high residual oxygen isn’t just a quality issue—it’s a brand-killing logistical nightmare that leads to lost revenue and flat flavor. Achieving the “holy grail” of <1% residual oxygen is possible with the right equipment and nitrogen flushing coffee protocols from newideapack.

Why is <1% residual oxygen the gold standard for coffee?

Achieving <1% residual oxygen is the benchmark for specialty roasters because it effectively halts the oxidation of lipids and oils. By mastering nitrogen flushing coffee, you ensure that the complex flavor profile you worked hard to roast stays intact for the consumer. This level of precision is what separates premium brands from mass-market products.

The Science of Staling

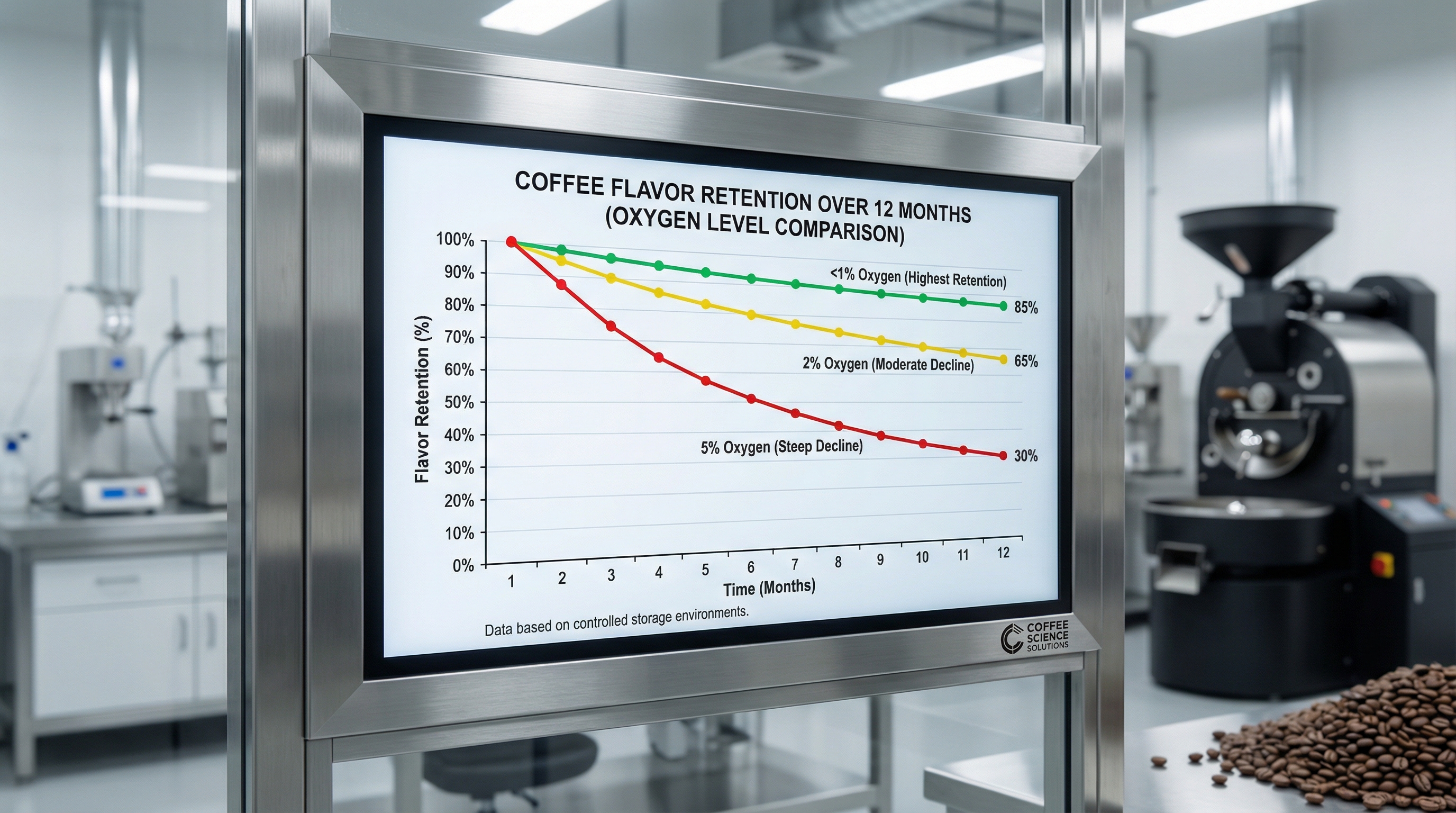

The chemical breakdown of coffee oils is accelerated by even small amounts of oxygen. At 5% oxygen, flavor declines rapidly within three months.

Look:

Here is the bottom line: under 1% oxygen, those same beans can maintain peak freshness for over a year.

Sensory Differences

When you reduce oxygen levels, you preserve the volatile aromatics that define a “specialty” roast. This results in a better cup profile for your end-user.

- Higher acidity retention.

- Intense floral and fruity notes.

- Longer-lasting crema for espresso.

Key Takeaway: Reducing oxygen to <1% is the only way to guarantee a 12-month shelf life for specialty coffee.

| Metric | 5% Oxygen | <1% Oxygen |

|---|---|---|

| Shelf Life | 3 Months | 12+ Months |

| Flavor Integrity | Low | High |

| Market Value | Standard | Premium |

How does nitrogen flushing actually preserve coffee flavor?

The process works by using an inert gas to physically push oxygen out of the packaging before it is sealed. When you implement nitrogen flushing coffee, you are replacing reactive air with nitrogen, which does not interact with the coffee oils. This creates a stable internal environment that locks in the aroma.

The Displacement Mechanism

The machine purges the bag with a high-purity nitrogen stream just before the final seal. This displacement happens in milliseconds but is vital for long-term stability.

- Purge and seal cycle.

- Inert gas barrier.

- Displacement of ambient air.

Preventing Volatile Loss

Nitrogen creates a slight internal pressure that helps keep the aromatic gases inside the coffee bean cells. This prevents the “flat” taste often associated with older beans.

The best part?

Nitrogen is completely tasteless and odorless, so it never alters your roast’s unique profile.

Key Takeaway: Nitrogen acts as a protective shield that prevents chemical reactions and aromatic loss.

| Feature | Function | Benefit |

|---|---|---|

| Inert Gas | Replaces O2 | Stops oxidation |

| Internal Pressure | Holds aromatics | Better scent |

| Rapid Purge | High speed | High production |

What equipment is necessary for high-efficiency flushing?

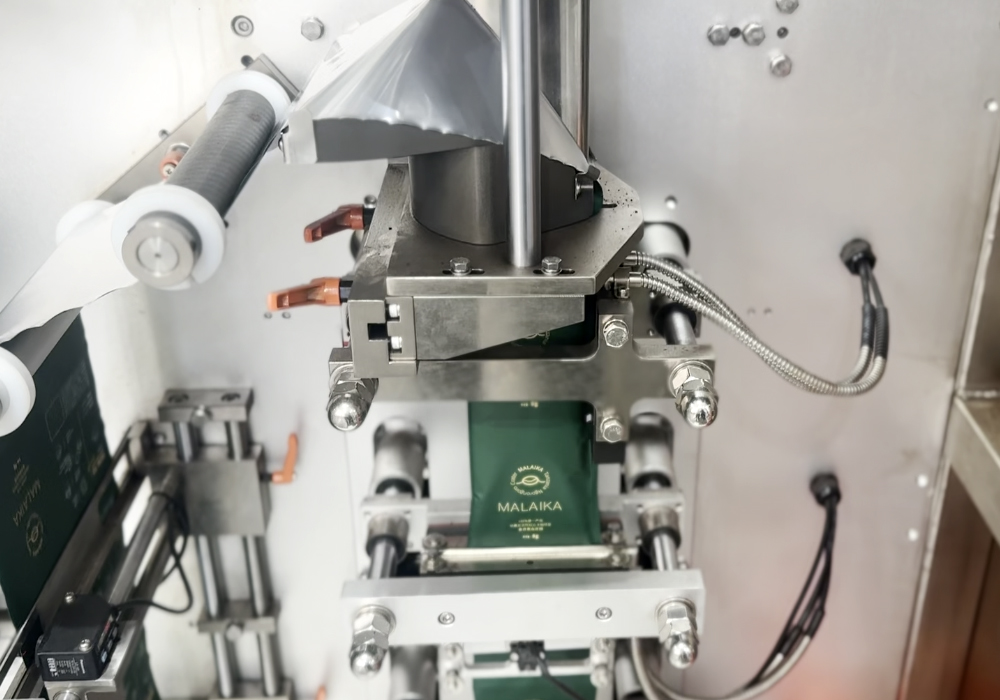

You need specialized industrial machinery equipped with precision gas injection manifolds and integrated oxygen sensors. To achieve professional results, nitrogen flushing coffee requires a system that can synchronize gas flow with the mechanical speed of the bagger. Newideapack provides the nitrogen flushing coffee hardware needed to hit these tight technical specs.

High-Precision Gas Injection

The design of the manifold determines how evenly the nitrogen is distributed within the bag. A well-designed nozzle prevents oxygen pockets from being trapped in the corners.

- Multi-port manifold design.

- Directional nozzles.

- Adjustable flow regulators.

Integrated Oxygen Analyzers

Real-time monitoring is the only way to ensure every bag meets your quality standards. These sensors detect deviations immediately, allowing for instant machine adjustments.

Think about it:

Without constant monitoring, a tiny mechanical slip could ruin an entire batch of premium coffee.

Key Takeaway: Quality MAP results depend on the synergy between gas injection precision and real-time sensor feedback.

| Equipment | Purpose | Importance |

|---|---|---|

| Manifold | Even gas distribution | Critical |

| Gas Sensor | Monitors O2 levels | Mandatory |

| PLC Controller | Syncs cycles | Essential |

How do you optimize gas flow rate for maximum displacement?

Optimization requires finding the perfect balance between gas pressure and the duration of the flush. During the process of nitrogen flushing coffee, excessive pressure can cause turbulence, which actually sucks ambient air back into the bag. You must calibrate your flow rate to create a smooth, laminar flow that clears the headspace efficiently.

Balancing Pressure and Velocity

High velocity is good for speed, but low turbulence is better for oxygen removal. Finding the “sweet spot” ensures the oxygen is pushed out without mixing.

But there’s a catch:

If the flow is too weak, the heavy oxygen molecules won’t be fully displaced before the seal closes.

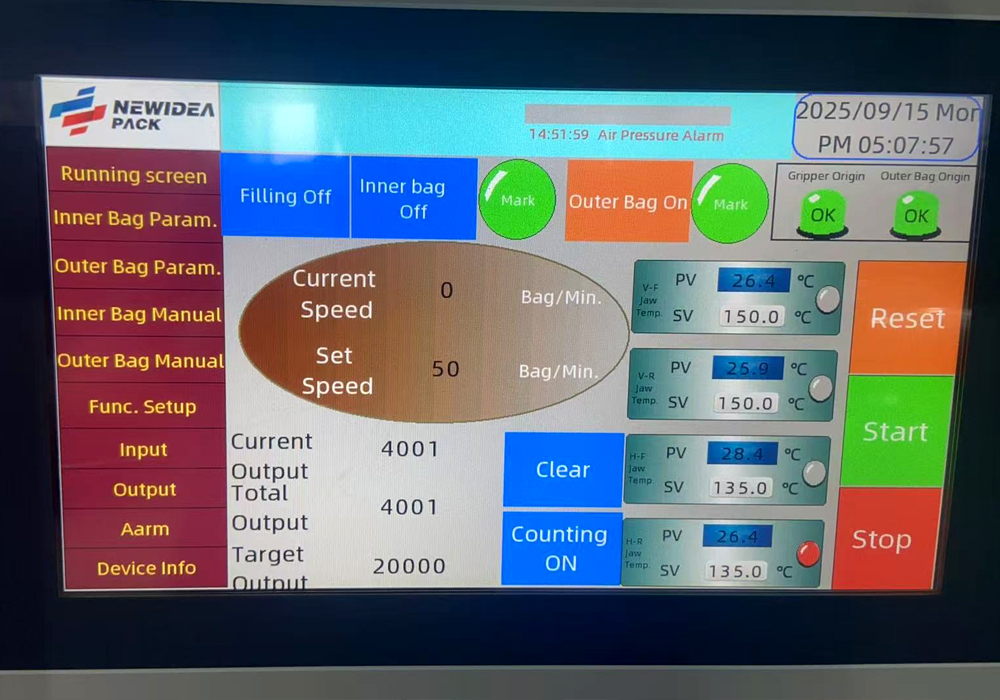

The Timing Secret

The nitrogen must be injected at the exact microsecond the bag is formed but before the seal is crimped. This coordination is handled by the high-speed PLC in newideapack machines.

- Millisecond synchronization.

- Dwell time adjustment.

- Cycle speed matching.

Key Takeaway: Effective gas displacement is a product of timing and controlled velocity, not just brute pressure.

| Variable | Ideal Setting | Impact |

|---|---|---|

| Pressure | 2.0 – 3.0 Bar | Prevents turbulence |

| Flow Rate | 120 L/min | Ensures volume |

| Timing | <50ms | Maximizes purity |

Why does the sealing mechanism affect oxygen levels?

Even a perfect nitrogen flush is useless if your seal allows oxygen to leak back into the bag over time. If you want to master nitrogen flushing coffee, you must invest in high-integrity sealing technology. Standard heat seals are prone to micro-leaks, especially if coffee dust gets caught in the seal area.

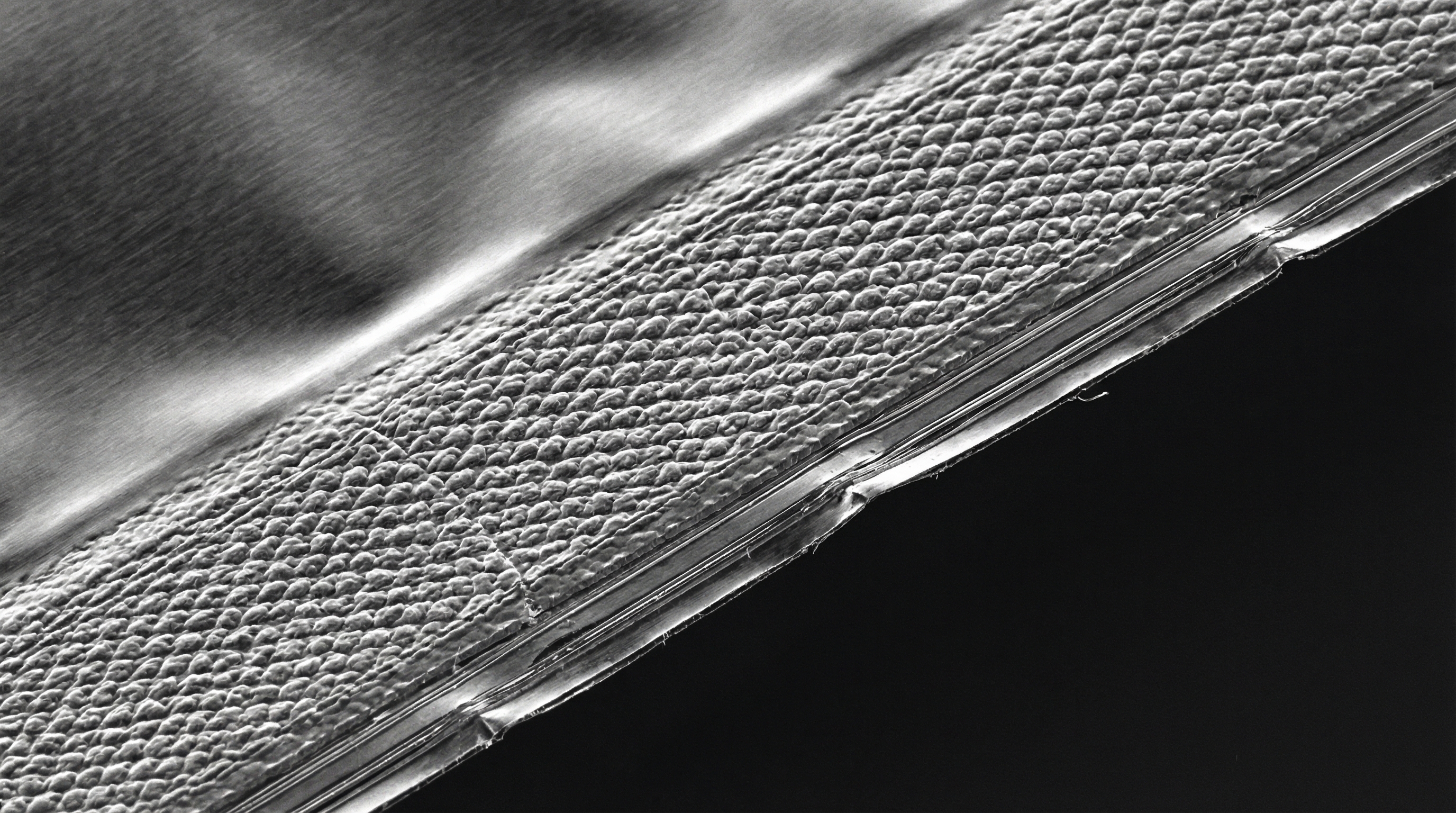

Micro-leakage Risks

Microscopic gaps in a seal are often invisible to the naked eye. However, they are large enough for oxygen molecules to slowly penetrate and ruin the coffee within weeks.

- Poor heat distribution.

- Product contamination in seal.

- Film thickness variations.

The Ultrasonic Advantage

Ultrasonic sealing uses high-frequency vibrations to create a molecular bond between the film layers. This process effectively vibrates away coffee dust and oils from the seal interface.

In fact:

This technology provides the most reliable hermetic barrier available for the drip coffee bag market today.

Key Takeaway: A hermetic seal is the final gatekeeper that maintains the <1% oxygen level achieved during flushing.

| Seal Type | Contamination Handling | Barrier Quality |

|---|---|---|

| Standard Heat | Poor | Variable |

| Ultrasonic | Excellent | Superior |

| Cold Seal | Good | Moderate |

What role does coffee degassing play in oxygen management?

Freshly roasted coffee naturally releases carbon dioxide (CO2), which can interfere with your nitrogen levels. When you perform nitrogen flushing coffee, you have to account for this outgassing. If the bag is sealed too early without a valve, the buildup of CO2 can cause the bag to bloat or even burst.

Managing CO2 Outgassing

Roasters often allow beans to “rest” for a few hours to release the most aggressive gases. However, too much resting exposes the beans to the very oxygen you are trying to avoid.

Look:

The trick is to package quickly and use technology to manage the internal gas environment.

One-Way Valve Integration

One-way valves are essential for allowing CO2 to escape while preventing any outside oxygen from entering. This maintains the high-purity nitrogen environment you created during packaging.

- Pressure relief function.

- Oxygen exclusion.

- Aroma retention.

Key Takeaway: Degassing valves are a necessary partner to nitrogen flushing for maintaining package structural integrity.

| Component | Role | Outcome |

|---|---|---|

| Nitrogen | Displaces Oxygen | Stops aging |

| CO2 | Escapes Valve | Prevents bursting |

| One-Way Valve | Blocks O2 entry | Maintains MAP |

How can ultrasonic sealing improve your MAP results?

Ultrasonic sealing is a game-changer for nitrogen flushing coffee because it ensures a perfect seal even in “dirty” environments. In a typical nitrogen flushing coffee setup, fine coffee particles often land on the seal rim. Traditional heat sealers can’t melt through this dust, but ultrasonic waves blast it out of the way.

Sealing Through Contamination

The ultrasonic horn focuses energy only on the seal interface, vibrating at 20kHz or higher. This localized energy liquifies the film and pushes out any dust, oils, or grounds.

- Clears seal area.

- High-strength bonds.

- Zero “leaker” bags.

Cold Sealing Benefits

Because the horn doesn’t stay hot, it doesn’t warp or weaken the surrounding packaging material. This preserves the oxygen barrier properties (OTR) of your expensive high-barrier films.

Specifically:

This prevents the “thinning” of the plastic that often occurs with traditional high-temperature heat sealers.

Key Takeaway: Ultrasonic technology eliminates the #1 cause of MAP failure: product contamination in the seal.

| Feature | Heat Sealing | Ultrasonic Sealing |

|---|---|---|

| Dust Tolerance | Low | High |

| Energy Usage | High | Low |

| Seal Reliability | 95% | 99.9% |

What are the most common mistakes when implementing nitrogen flushing?

Many roasters fail because they use low-purity nitrogen or cheap packaging films. To get the best out of nitrogen flushing coffee, you must use gas that is at least 99.9% pure. If your nitrogen contains even a small amount of oxygen, you will never hit that <1% residual target.

Incorrect Gas Purity

Using 95% or 98% pure nitrogen is a common cost-cutting mistake. This results in “residual” oxygen that is already too high before the bag is even finished.

Why?

Even a 1% difference in gas purity can lead to a 50% reduction in shelf life.

Poor Bag Material Selection

If you use a film with a high Oxygen Transmission Rate (OTR), oxygen will simply seep through the plastic over time. You must use high-barrier laminates like foil or metalized PET.

- Thin film with no foil.

- Incorrect OTR ratings.

- Non-barrier plastics.

- Damaged film rolls.

Key Takeaway: Your results are only as good as your gas purity and your film’s barrier strength.

| Error | Consequence | Solution |

|---|---|---|

| Low Gas Purity | High residual O2 | Use 99.9% N2 |

| Poor Film | Oxygen seepage | Use high-barrier |

| Weak Seals | Immediate leaks | Use Newideapack tech |

How does <1% oxygen impact your business ROI and growth?

Extending your shelf life from 3 months to 12 months allows you to expand your distribution radius significantly. By investing in nitrogen flushing coffee technology, you can ship your products internationally without fear of them arriving stale. Newideapack helps roasters scale by providing the technology needed to compete on a global stage.

Extending Distribution Radius

With a 1-year shelf life, you can sell to large retail chains and overseas distributors. This increases your potential market size from local to global overnight.

- International shipping.

- Longer retail windows.

- Bulk distribution.

Reducing Product Waste

When coffee stays fresh longer, you see a massive drop in “expired stock” returns from your retailers. This directly improves your bottom-line profitability and brand reputation.

Fortunately:

The cost of nitrogen is a tiny fraction of the revenue lost to returned, stale coffee.

Key Takeaway: MAP is not a cost; it is an investment that unlocks high-volume, long-distance sales channels.

| Benefit | Impact | Result |

|---|---|---|

| Longer Shelf Life | 12+ Months | Global exports |

| Less Waste | -80% Returns | Higher profits |

| Brand Trust | Peak Freshness | Repeat customers |

What technical support ensures consistent nitrogen levels?

Consistency requires a combination of regular machine calibration and expert operator training. Even the best system for nitrogen flushing coffee needs to be checked every shift to ensure the sensors are accurate. Newideapack provides comprehensive support to help you maintain these high standards year-round.

Calibration and Maintenance

Oxygen sensors can drift over time due to humidity and temperature changes. Daily calibration against a known standard is the only way to trust your data.

The best part?

Newideapack systems feature easy-access ports for quick sensor verification during production runs.

Operator Training

Your team needs to know what to do when oxygen levels start to creep up. Proper training ensures they can troubleshoot gas flow or seal temperature issues before they become disasters.

- Sensor check protocols.

- Gas flow troubleshooting.

- Seal integrity testing.

Key Takeaway: High-performance packaging is a “check and verify” process that requires both great tech and trained people.

| Task | Frequency | Purpose |

|---|---|---|

| Sensor Calibration | Daily | Ensure accuracy |

| Seal Inspection | Hourly | Prevent leaks |

| Operator Audit | Monthly | Maintain standards |

Maintaining the freshness of your roast is the foundation of coffee brand loyalty. At newideapack, we don’t just sell machines; we provide the precision engineering and Modified Atmosphere Packaging (MAP) expertise required to protect your product’s integrity.

Frequently Asked Questions

Can I achieve <1% oxygen with ground coffee as easily as whole bean?

No, it is harder. Ground coffee has more surface area and trapped air, requiring a longer or more intense nitrogen flush.

How do I test the residual oxygen levels in my finished bags?

Use a needle-based analyzer. You pierce the bag through a foam septum to extract a sample for the sensor to read.

Does nitrogen flushing change the flavor profile of the coffee?

No. Nitrogen is an inert gas that is tasteless and odorless, so it only preserves the flavor you’ve already created.

Is nitrogen flushing cost-effective for small roasters?

Yes. While it adds a small cost per bag, the reduction in waste and the ability to sell to farther markets provide a high ROI.

How often should I calibrate my packaging machine’s nitrogen flow?

Every shift. Regular calibration ensures your sensors haven’t drifted and that your oxygen levels remain below the 1% target.

Ready to achieve the <1% oxygen benchmark and scale your roasting business?

To get a custom MAP audit for your production line, contact us today.