Newideapack ND-VFC500G Vertical Form Filling Sealing Granule Packaging Machine

1

Frame film shaft

2

shaper

3

Pull film wheel

4

prong knife

5

pallet

6

Operation panel

Mechanical Components

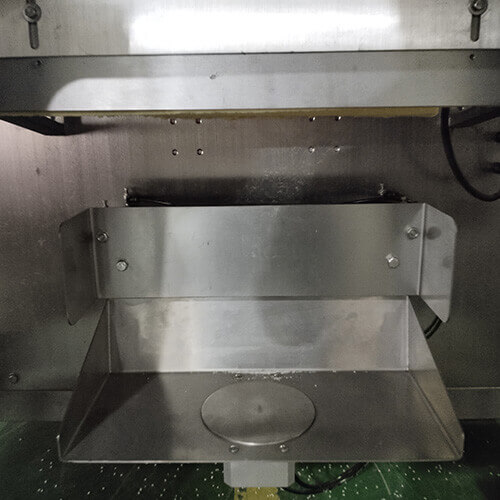

- 1: Frame film shaft

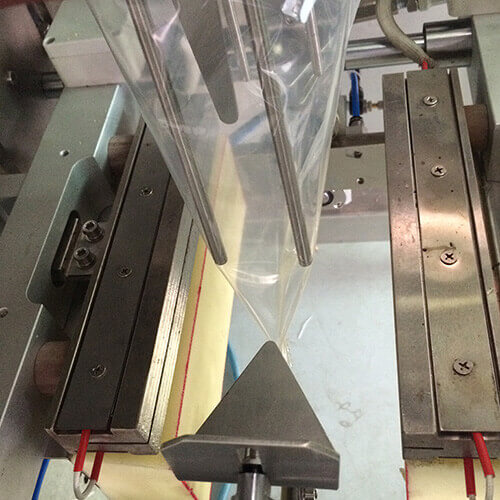

- 2: shaper

- 3: Pull film wheel

- 4:prong knife

- 5: pallet

- 6: Operation panel

Performance Parameter

Max Speed

40 bpm

Bag Size

Min Size:200mm*300mm

Max Size:500mm*9500mm

Description

Specification

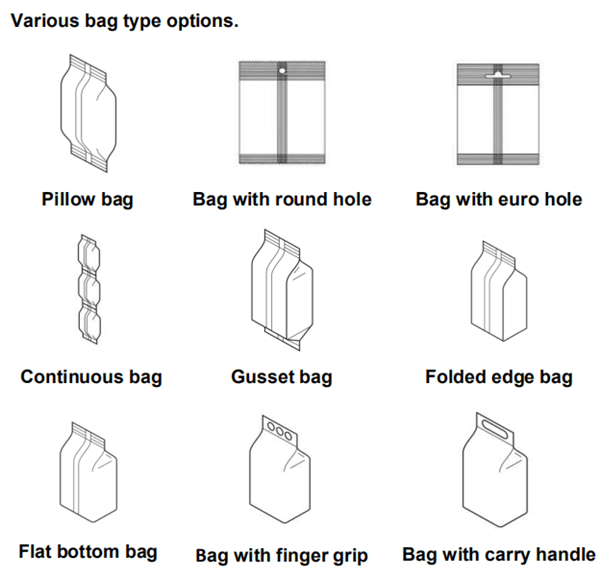

Bag Type Options

Solution

FAQ

Description

Granule Vertical Form Filling Sealing Packaging Machine

Suitable for 3kg-20kg of various granules products, that normally are large package are for daily supplies consumables, factory materials, restaurant materials, like frozen food, grains, ice cubes, sugar, salt, washing powder, etc. suitable for laminates packing material, transparent package, polyethylene material.

Feature

1. Multi-language color human-computer interaction interface, intuitive and simple operation.

2. Adopt Japanese Mitsubishi or France Schneider PLC control system, can store 10 kinds of product parameters, and adjust parameters without stopping the machine.

3. Intelligent detection, correction detection (correction motor, touch screen operation), length detection (cursor, encoder), the error range is±1mm .

4. The temperature control system adopts the Japanese Omron temperature control meter, and the horizontal and vertical sealing are independent temperature control; the sealing system adopts SMC cylinder, which is suitable for various composite films and PE films, and the packaging is beautiful and firm.

5. No film, no material, no ribbon, automatic alarm, open door and shutdown alarm, failure alarm. Make sure the safe and smart operation.

6. Low failure rate, high efficiency and stability, safe production for more than 10 years.

7. Machine welding structure is open, convenient for maintenance and cleaning.

Basic Associated equipment, makes the machine give full play to its advantages. Realize automatic lifting, weighing, filling, bag making, sealing, cutting, output.

Machine Drawing

Specification

| 1 | Model | ND-VFC500 |

| 2 | Output | 5-40 bags/minute |

| 3 | Filling Range | 5-100L |

| 4 | Bag length | 300-1000 mm |

| 5 | Bag width | 200-510 mm |

| 6 | Max Film Width | 1050 mm |

| 6 | Max Film Width | 1050 mm |

| 7 | Film Roll Diameter | Inner 75 mm, outer max 400 mm |

| 8 | Air Pressure | 0.8mpa |

| 9 | Air consumption | 0.8m3/m |

| 10 | Voltage power/ Frequency | 220V/380V, 7.5KW, 50Hz |

| 11 | Machine weight | 900kgs |

| 12 | Machine dimension | 2600*1740*2440(L*W*H, mm) |

Bag Type Options

Solution

Model VFC500, specially for packaging products into big bags. Max bag range is 100L. For granule products can pack from 3 kg-25 kg, like frozen vegetables, frozen fruits, frozen French fries, frozen seafood, frozen meats, cooked beans, rice, grains, salt, sugar, ice cubes, detergent, barbecue charcoal and so on. Most of them are for family package, convenient to store.

As most of the products in the large package are for daily supplies consumables, the manufacturer often choose sample and economical packing material to control the cost. Except laminates packing film, most of them will choose polyethylene material, some with printing, some without printing.

Please click here for case study.

FAQ

How to solve the film deviation?

1、The position of the roll film can be quickly corrected by the correction device on the touch screen

2、Check whether the position of the center line of the film roll on the air shaft is in a straight line with the center line of the former

3、More solution you can contact us for assistant

How to solve the problem that the machine does not pull the film?

1、Check whether the longitudinal sealing block is stuck with the roll film, and clean the longitudinal sealing block.

2、Check whether the belt is slippery, clean the surface of the belt with a damp cloth

3、More solution you can contact us for assistant