How AI is Revolutionizing Coffee Packaging Automation

AI is transforming the coffee packaging industry, making processes faster, more efficient, and more accurate. But how exactly is AI revolutionizing coffee packaging automation? From robotic systems to machine learning algorithms, AI is enhancing every stage of the packaging process, from sorting and filling to sealing and labeling, allowing for higher precision and reduced costs.

In this article, we’ll explore the role AI plays in revolutionizing coffee packaging automation. By diving into the technologies driving this change and the benefits they offer, you’ll see how AI is enabling brands to not only meet the growing demand for coffee but also stay ahead in a highly competitive market.

1. How is AI Revolutionizing Coffee Packaging Automation?

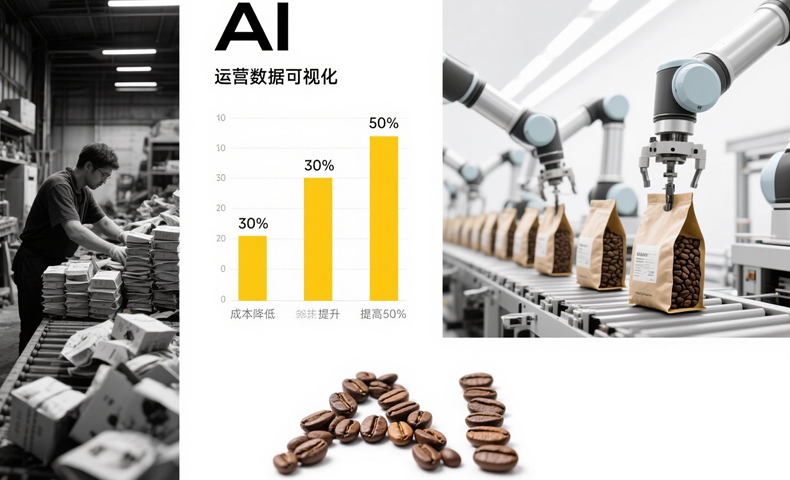

AI is fundamentally changing the way coffee packaging operates. Traditionally, coffee packaging involved manual labor and limited automation, which meant higher costs, slower production speeds, and a higher likelihood of errors. Today, AI-powered machines are enhancing every stage of the packaging process. How does AI do this? By using advanced algorithms, machine learning, and robotics, AI can automate tasks, reduce human error, and increase speed and efficiency, making the entire process more streamlined.

Key Advancements in Automation Driven by AI

● Integration of machine learning to predict and optimize packaging performance.

● Robotics used for handling delicate packaging and reducing human intervention.

● AI-based systems that monitor and adjust packaging lines in real time.

The Benefits of AI in Coffee Packaging

● Increased accuracy and consistency in packaging.

● Improved efficiency, reducing production times.

● Lower operational costs with fewer errors and reduced waste.

| AI Technology | Impact on Coffee Packaging |

|---|---|

| Machine Learning | Improves decision-making for optimal packaging performance. |

| Robotics | Increases precision in packaging and reduces human labor. |

| Real-Time Monitoring | Ensures continuous optimization of packaging speed and quality. |

2. What Are the Key AI Technologies Used in Coffee Packaging?

AI technologies in coffee packaging automate repetitive tasks, boost productivity, and ensure consistent quality. The most prominent AI technologies in use today are machine learning, robotics, and computer vision. But how do these technologies fit into the packaging process?

Machine Learning for Smarter Packaging Systems

● Predictive algorithms to adjust packaging settings in real time.

● Adaptive systems that improve with experience, optimizing packaging methods.

Robotics and AI for Precise, Consistent Packaging

● Robotic arms designed to handle coffee bags with precision.

● AI-powered robotics that can handle multiple types of packaging formats.

Computer Vision in Quality Control and Inspection

● AI-powered cameras and sensors for defect detection.

● Ensuring product consistency with computer vision systems that check each package for errors.

| Technology | Role in Coffee Packaging Automation |

|---|---|

| Machine Learning | Predicts and optimizes packaging processes to improve efficiency. |

| Robotics | Provides precision and flexibility, reducing human error. |

| Computer Vision | Detects defects, ensuring high-quality packaging with fewer mistakes. |

3. How Does AI Improve Efficiency in Coffee Packaging?

AI boosts efficiency by automating manual tasks, improving speed, and reducing downtime. Traditional coffee packaging lines required frequent manual interventions, which slowed down production and led to inconsistencies. With AI, packaging lines can run faster with minimal supervision. What are the key ways AI improves efficiency in packaging? AI systems can make adjustments on the fly, increase throughput, and reduce the need for human oversight, freeing up workers to focus on more complex tasks.

Automating Repetitive Tasks to Increase Production Speed

● AI-based machines that can fill, seal, and label packaging with minimal human input.

● Robots that can work continuously without rest, increasing production capacity.

Reducing Errors and Minimizing Waste

● AI systems that detect errors and adjust operations to prevent defective products.

● Reducing packaging material waste by optimizing material use.

| Efficiency Factor | Impact on Packaging Process |

|---|---|

| Automation | Speeds up production, reducing labor costs and improving throughput. |

| Error Detection | Reduces errors by adjusting operations and ensuring high-quality outputs. |

| Material Optimization | Cuts waste by ensuring the right amount of packaging materials are used. |

4. What Are the Advantages of AI in Coffee Packaging Automation?

AI in coffee packaging offers significant advantages in terms of cost, speed, and product quality. AI can help companies increase their output while maintaining high standards of quality. What are the primary benefits of using AI in coffee packaging?

Enhancing Packaging Precision and Reducing Human Error

● AI-driven systems provide a higher degree of precision compared to manual operations.

● Machine learning algorithms ensure consistent results, eliminating human errors that could cause product defects.

Improving Product Consistency and Quality

● AI ensures every package meets the same quality standards, reducing variance between products.

● Packaging lines optimized by AI run at an even pace, ensuring uniformity.

| AI Advantage | Benefit to Coffee Packaging |

|---|---|

| Precision | Minimizes errors and enhances the accuracy of packaging. |

| Consistency | Ensures that all coffee packages are uniformly sealed, labeled, and filled. |

| Quality Control | Guarantees that the packaging meets the highest standards, reducing waste. |

5. How Can AI Reduce Costs in Coffee Packaging Automation?

Implementing AI in coffee packaging automation can significantly lower operational costs. By increasing efficiency, reducing errors, and optimizing resource usage, AI helps coffee brands stay competitive and maintain their bottom line. How can AI specifically cut costs? AI can lower labor costs, reduce waste, and improve energy efficiency, all of which contribute to long-term savings.

Reducing Material Waste Through Predictive Algorithms

● AI predicts the amount of material needed, reducing excess and waste.

● Optimizing material usage lowers production costs and improves sustainability.

Minimizing Downtime With Real-Time Monitoring and Optimization

● AI systems monitor production lines in real-time, identifying bottlenecks or problems before they cause downtime.

● Maintaining continuous production with minimal interruptions reduces costs.

| Cost-Reduction Factor | Effect on Packaging Process |

|---|---|

| Material Optimization | Reduces waste and ensures materials are used efficiently. |

| Real-Time Monitoring | Keeps operations running smoothly, minimizing downtime and maintenance costs. |

| Labor Savings | Reduces the need for manual labor, lowering overall labor costs. |

Conclusion

AI is revolutionizing coffee packaging automation by enhancing efficiency, improving precision, and reducing costs. From optimizing material use to streamlining production processes, AI is transforming how coffee brands meet consumer demand with speed, accuracy, and minimal waste. By embracing AI technologies, coffee brands can stay competitive, improve quality control, and create a more sustainable future.

FAQ Section

- Q1: What is AI in coffee packaging automation?

AI in coffee packaging automation involves using machine learning, robotics, and computer vision to enhance the efficiency, accuracy, and quality of coffee packaging processes. - Q2: How does AI improve efficiency in coffee packaging?

AI improves efficiency by automating tasks, reducing human error, and optimizing the use of resources, which increases production speed and minimizes waste. - Q3: What are the benefits of using AI in coffee packaging?

AI offers numerous benefits, including improved packaging precision, better product consistency, and reduced costs by minimizing waste and lowering labor requirements. - Q4: How can AI reduce costs in coffee packaging automation?

AI helps reduce costs by optimizing resource use, decreasing material waste, minimizing downtime, and lowering labor costs through automation. - Q5: What are the key AI technologies used in coffee packaging?

The key AI technologies include machine learning, robotics, and computer vision, which work together to automate tasks, improve quality control, and streamline packaging processes.