5 Questions About VFFS Machines

5 Questions About VFFS Machines

Vertical form fill seal (VFFS) is the abbreviation of vertical packaging machine, which has a very wide range of applications in the packaging machine industry. It is a machine with strong packaging capacity and can be used for various small granule or powders. Physically suitable for food and non-food products, the biggest feature is continuous packaging, which greatly saves time and labor costs.

As a professional packaging machinery manufacturer, Tianjin Newideapack Ltd has prepared 5 hot contents about VFFS packaging machines for you. It is convenient for you to have a deeper understanding of vertical packaging machines, and ensure that some unnecessary problems are avoided in the process of purchasing VFFS packaging machines.

Tip 1: The working principle of vertical packaging machine

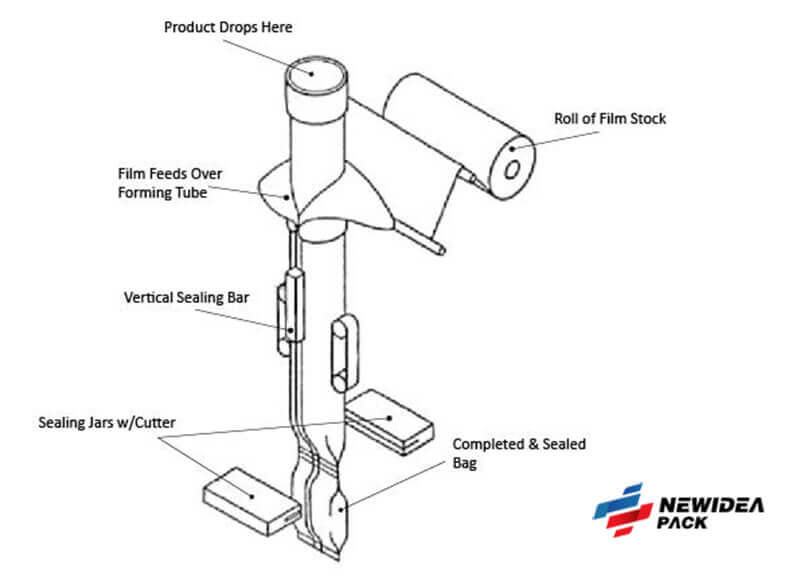

The VFFS packaging machine is a product that makes the soft roll film to making a bag, measurement and filling in automatic and packaging bag sealing and arranging in three steps in automatic, and its working principle is as follows: the rolled packaging bag film raw material is passed through The guide rods are transferred to the forming tube, which is preset to the required travel size and diameter according to the type and volume of the package. When the length of the traveling cylindrical packaging bag reaches the preset position, the vertical packaging machine performs the joint heat sealing and cutting work. (See Figure 2 for the schematic diagram).

Step One: the measurement and filling of the prepackaged Materials

Different products to be packaged have different measurement and filling methods. For example, granular products (such as potato chip packaging machines, coffee bean packaging machines) need electronic weighing or measuring cups, and powders need screw measurement (coffee powder packaging machines), The liquid and sauce are measured with a liquid pump or a sauce pump (putty paste packaging machine), and the filling amount can be set by controlling the filling time of the other materials to be packaged. Once the material to be filled reaches the preset filling amount, the feeder will stop the feeding action and proceed to the next step of sealing the entire work.

Step Two: bag making

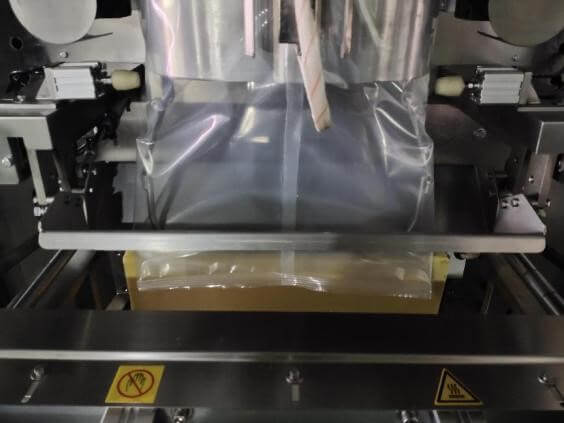

First of all, the power unit of the machine transfers the rolled raw material film of the packaging bag to the upright cylindrical pole, and according to the weight and volume of the object to be packaged, a cylindrical packaging bag of corresponding length and diameter is produced, and the bottom and side are carried out. seal. Different vertical packaging machines have different sealing methods to choose from.

Step Three: Sealing and arrange of the bag

Different materials to be packaged will affect the sealing method of the packaging bag to some extent, especially for gas and liquid products. So how to seal the bag quickly and effectively depends on the comprehensive performance of the vertical packaging machine. The reason why Newideapack’s vertical packaging machine is favored by many customers in the packaging machine industry is because of the stable and reliable excellent performance of our products in this link.In addition, it is also necessary to print the product production date and production batch information on the packaging bag, and even punch the packaging bag so that the product can be hung on the shelf in the supermarket in the future. All custom bag setups place higher performance demands on vertical packers. But you don’t have to worry about it, Newideapack is fully capable of solving all the technical problems for you and giving you a very cost-effective vertical packaging machine.

Tip Two: How To Operate The VFFS Packaging Machine

Different types of vertical packaging machines have completely different operation methods. Our Italian design team has fully considered various problems that may be encountered during the operation of vertical packaging machines. Therefore, Newideapack’s vertical packaging machine is convenient and simple to operate, and safety precautions ensure that there will be no danger.

In general, the operation of the vertical packaging machine is divided into 5 steps

Step One: Installation of vertical packaging machine and preparation of packaging raw materials

After fixing the vertical packaging machine in the predetermined position in the production workshop, check whether there is any inclination and unevenness. Then place the raw material of the packaging bag on the corresponding support. Then align the edge of the raw material of the packaging bag with the gap between the brackets parallel and perpendicular. The purpose of this is to prevent the raw material of the packaging bag from curling during the feeding process.

Step Two: Check and prepare the power supply

The power source of the entire vertical packaging machine is the power supply, so the stable output of the power supply is very important. Before turning on the power, please carefully check whether the power supply meets the working requirements of the vertical packaging machine. Too high or too low voltage may cause damage to the machine.

In addition, you also need to carefully check the environment of the wire and line to ensure that the wire is not broken, whether the connection at the interface is firm, and whether there is stagnant water or other conductive environments on the path of the wire. Try to keep the power supply environment in a dry and clean state.

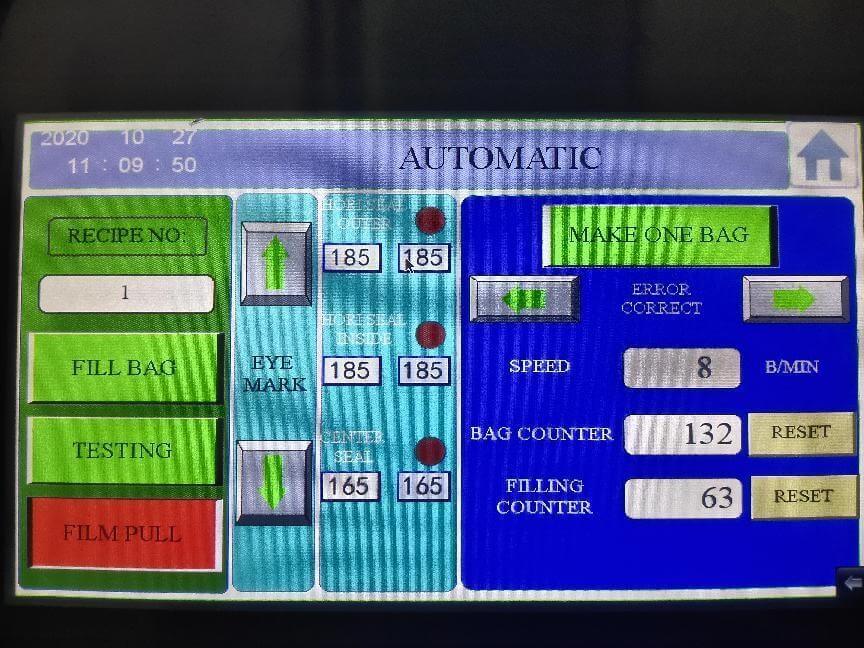

Step Three: Set the operating parameters of the vertical packaging machine

Our vertical packaging machines are equipped with independent machine operation control panels. On the control panel, we need to set the length and temperature parameters of the packaging bags. Then set the parameters of the package weight.

If you have more customization requirements, you can contact our technical staff. We will customize the control language, control parameters and other functions of the control panel according to your actual packaging needs. You don’t have to worry about the language of the control panel being difficult to understand. Control security issues.

Step Four: filling the prepackaging material into the VFFS

There is a feeding port on the outside of the vertical packaging machine. Usually, we will equip it with a funnel-type device, so that the objects to be packaged can enter the vertical packaging machine smoothly. Due to the special properties of some materials to be packaged, it is easy to cause the feeding port to be blocked, so we need to observe and clear the feeding port in time.

Step Five: pay attention to the entire VFFS system running status.

After the machine has been commissioned, the vertical packaging machine will run fully automatically, during which we do not need to do anything. You only need to observe whether there is any bad situation during the operation of the packaging machine. If there is any, please stop the operation of the vertical packaging machine immediately. In addition, you also need to observe whether the raw materials of the packaging bags are used up, please replenish them in time before they are used up to avoid problems. The last detail that needs to be paid attention to is that the finished product packaging needs to be sorted out in time so as not to block the discharge port of the vertical packaging machine.

Tip Three: The Working Range of VFFS

Compared with horizontal packaging machines, vertical packaging machines are more suitable for small-volume, granular or liquid items. According to our many years of manufacturing experience, the packaging machine users of Newideapack brand most commonly use the packaging of coffee beans and coffee powder when purchasing our vertical packaging machine.

In order to let more potential users of vertical packaging machines understand the vertical packaging machines of the Newideapack brand, we have specially developed vertical packaging machines for packaging different coffee raw materials. These different vertical coffee packaging machines have different performance and scope of application, the following is a link to their detailed introduction.

Tip Four: Maintenance Of Vertical Packaging Machines

- For the heat sealer body of the vertical packaging machine, it should be cleaned frequently to ensure a clear seal texture.

- After the vertical packaging machine stops running, the measuring and weighing parts should be cleaned in time, such as the residue of sugar, salt and other debris. It must be ensured that the weighing plate and turntable are cleaned after each run to prevent corrosion.

- The scattered materials on the material tray should be cleaned up in time to keep the vertical packaging machine clean.

- The photoelectric tracking head, that is, the electric eye, should be cleaned regularly to ensure the small error of cursor tracking.

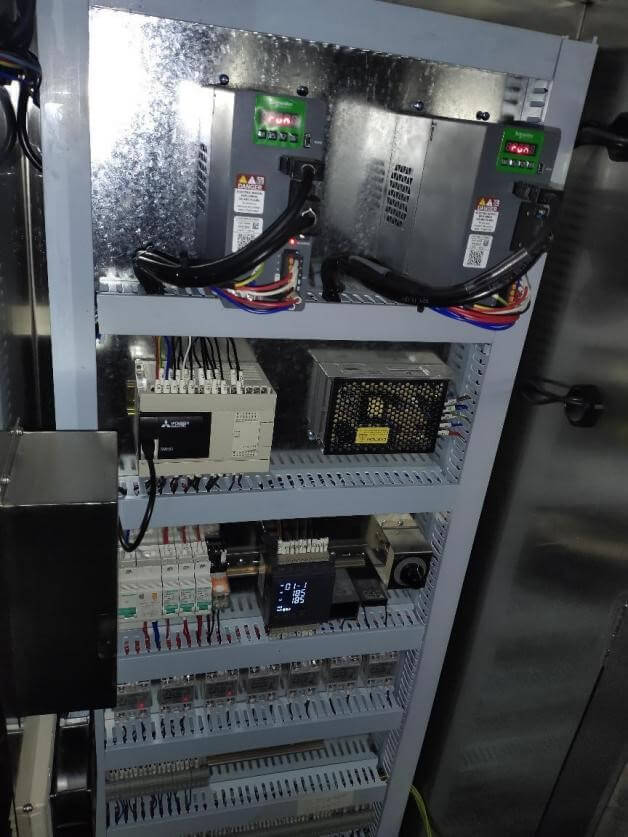

- Regularly clean the dust in the electrical control box to prevent poor contact and other malfunctions. Newly installed machines must be inspected, tightened, oiled and serviced within one week of use; transmission and moving parts must be maintained thereafter; after that, regular monthly inspections and maintenance must be performed

- Pay attention to the waterproof, moisture-proof, anti-corrosion and anti-rodent properties of electrical components. Electrical control cabinets and terminals should be kept clean to prevent electrical failures.

- Regularly check the screws of each part of the vertical packaging machine to prevent loosening

- Regularly check the gear net of the vertical packaging machine, the oil injection hole of the seat bearing and the lubrication of the movable parts. Note: When adding lubricating oil, be careful not to drip the lubricating oil on the transmission belt, so as to avoid belt slippage or loss of rotation, etc.

- When the vertical packaging machine stops running, the two heat-sealing rollers should be in the open position to avoid damage to the raw material of the packaging bag by being scalded by high temperature.

Tip Five: the select and purchase of VFFS

Obviously, this problem is the most concerned and most troublesome problem for all vertical packaging machine buyers. Different objects to be packaged have different properties and characteristics, so it is impossible for any multi-functional vertical packaging machine to meet all vertical packaging needs. So the real question for buyers to consider is – what kind of vertical packaging machine is the most suitable for their product packaging needs?Under normal circumstances, we will go through three processes in the process of selecting a suitable vertical packaging machine;

Process One: Clarify the packaging characteristics of the product to be packaged

For example, for the same coffee packaging, the packaging properties of coffee powder and coffee particles will correspond to different functional requirements for vertical packaging machines. Solid and liquid objects to be packaged will also be very different when designing the specific functions of the packaging machine. So when you are not sure how the vertical packaging machine you need should be constructed, please communicate with the vertical packaging machine manufacturer in a timely manner.In the process of communication, you only need to tell their designers what kind of products you need to package, what unique packaging requirements these products have, and what form you want the products to be packaged in the end.

Process Two: The trade-off between the performance and price of the vertical packaging machine

Many times we will hear some people complain that the vertical packaging machine they purchased is expensive and not fully functional. In fact, what they complain about is the mismatch between the functions that the vertical packaging machine can provide and their actual packaging needs. For a more in-depth analysis, in fact, there was no detailed communication with the vertical packaging machine manufacturer when purchasing.In the process of communicating with customers, many factories with functional vertical packaging machines often recommend existing mature vertical packaging machines to customers in order to save research and development costs, but obviously, such vertical packaging machines are usually designed for the purpose of In order to meet the needs of most customers as much as possible, the packaging function is often more comprehensive but not detailed enough. Therefore, it will cause many situations that are not very matched in actual packaging application scenarios. In addition, the manufacture of multi-functional vertical packaging machine equipment will naturally come with additional production costs, which also results in a low cost-effective situation for the vertical packaging machine purchased by customers.

Process Three: Measurement of payment delivery and after-sales service

After the communication in the above two links is correct, we must seriously consider the last link. The first is the delivery of the payment. After all, not every foreign trade purchase has the conditions to conduct an on-site inspection. The prepayment is often made by wire transfer. The packaging machine manufacturer will produce and deliver after receiving the deposit. To be safe, the balance can be paid by referring to the bill of lading.After-sales service is a very important factor in the entire packaging machine procurement process. After all, not every packaging machine operator is familiar with the working and design details of the packaging machine. Once the packaging machine fails or the parts are damaged, the packaging machine manufacturer needs to provide corresponding after-sales service. Whether it is email communication, video conference or arrangement of technical engineers to come to solve the problem, it will become a very decisive condition in the whole process of purchasing a vertical packaging machine.Well, the above is the relevant content of the 5 questions about the vertical packaging machine. If you are interested in our packaging machine or the hot information in the packaging machine industry, please contact us in time. We will provide you with the highest quality and most professional packaging machine solutions and the information you are most interested in!