What Are The Characteristics Of Automatic Frozen Food Packaging Machine

Maybe you are not necessarily very familiar with frozen food packaging equipment, nor do you know what characteristics frozen food packaging equipment has. You may even feel that this question should a practitioner think in the frozen food packaging industry. But in fact, because of the ongoing impact of COVID-19, many families have been forced to change their eating habits and structures.

When fresh food, which was easily available in the past, became out of reach, people all over the world developed the habit of hoarding food. Due to future uncertainty about the impact of the end of COVID-19, more and more people are choosing frozen packaged foods as one of the staples of the future. This has led to an urgent need for frozen food processors to find fully automatic frozen food packaging machines with higher frozen food packaging efficiency that can adapt to a variety of frozen food packaging types.

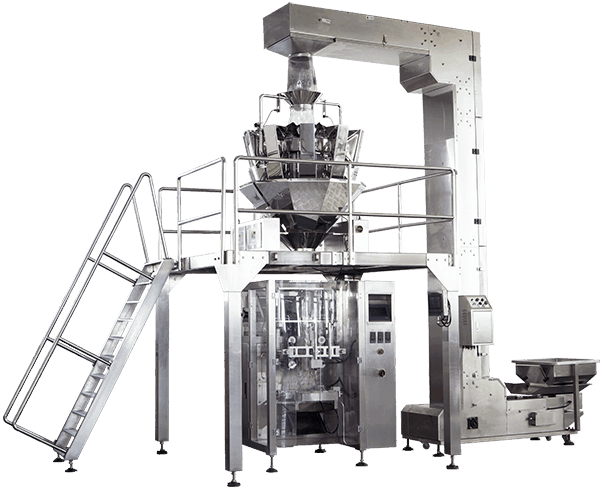

Fully automatic frozen food packaging machines usually work in a low temperature and humid environment. Factors such as ice slag and debris generated during the packaging process of various frozen foods often cause the packaging machine to malfunction. Therefore, the use of environmental factors in the design and manufacture of frozen food packaging machines will be more than ordinary food packaging machines.

NEWIDEAPACK, as a factory with more than 15 years of packaging machine design and manufacture, has provided various types of frozen food packaging machines to customers all over the world. Today, we combine years of professional experience to share with you the characteristics of fully automatic frozen food packaging equipment.

Feature One: Stainless steel is used as the main material of the packaging machine

Frozen foods tend to produce ice chips when they are packaged, and the ice chips turn into water when melted. When oxygen in water and air encounters iron, it chemically reacts to form rust. Rust is absolutely not allowed in the food packaging process. Therefore, when we manufacture automatic frozen food packaging machines, we will choose SUS304 stainless steel as the main material of the packaging machine to avoid rusting.

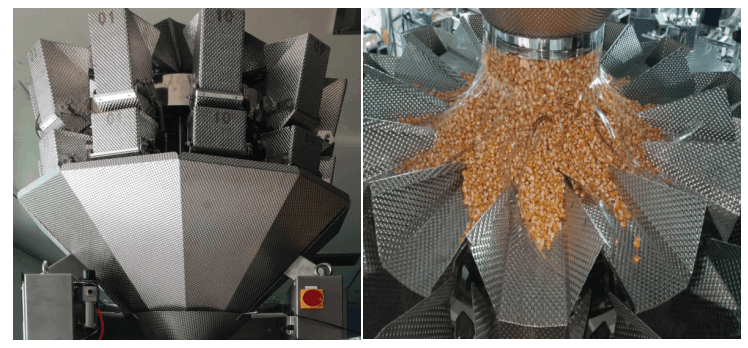

Feature Two: Precise frozen food weighing equipment

Because quick-frozen products generally use linear scales or multi-head scales when weighing, they achieve accurate weighing by adjusting the amplitude and load cell. The cold food reaches the small weighing hopper through vibration in the raw material silo. When the weight reaches the target weight value, the release port at the bottom of the small hopper is opened, and the frozen food is slid into the food packaging bag.

Usually, the outer surface of frozen food is relatively smooth due to the low-temperature condensation of water vapor, so when we manufacture the frozen food packaging machine, we design a small hopper for weighing the weight into concave and convex particles. In this way, the anti-skid treatment effect of the frozen food is effectively achieved, and the frozen food is weighed slowly and orderly, which greatly improves the weighing accuracy of the frozen packaging machine.

Feature Three: Frozen food packaging machine needs to have waterproof performance

Frozen foods are prone to produce ice cubes when they are packaged. If these ice cubes fall into the electronic components of the packaging machine, they will melt. The water melted by the ice chips will short-circuit the automatic frozen food packaging machine in the electronic components.

In order to solve this problem, NEWIDEAPACK adopts the IP65, or IP66 waterproof case, equipped with a drying water removal device and heating constant temperature device, to prevent the damage of electrical components or short circuits of electronic components caused by a humid environment. It effectively improves the safe operating environment of the frozen food packaging machine and greatly prolongs the service life of the packaging machine.

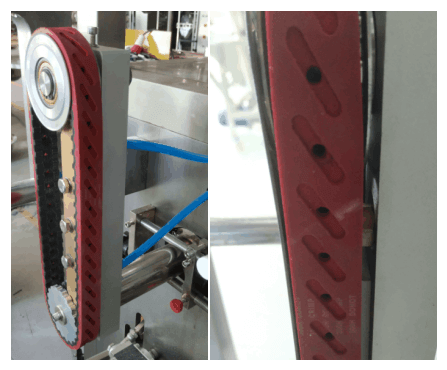

Feature Four: Equipped with a vacuum state packaging bag film stretching feeding system

When the vertical frozen food packaging machine is packaging frozen products, the stretch belt of the packaging bag film will slip due to the influence of water vapor, resulting in inaccurate positioning of the packaging bag film, different lengths of the packaging bags, and the frozen food being clamped by the sealer. The packaging bag is not tightly sealed, etc. The packaging bag film stretching feeding system in the vacuum state can isolate the water vapor from entering the stretching belt, and effectively avoid the occurrence of the above situation.

The above 4 points are the functions and characteristics that the automatic frozen food packaging machine must have. Compared with the traditional food packaging machine, the biggest difference is the moisture protection measures in the humid environment, which is caused by the special properties of frozen food. If you need to purchase fully automatic frozen food packaging machines or are interested in our other types of packaging machines, please contact our senior engineers. We will answer your questions as soon as possible and provide free packaging machine solutions.