What Are the Best Cold Brew Coffee Packaging Tech Specs for 15g-20g Filters?

To produce effective cold brew drip bags, you need specialized machinery capable of handling 15g-20g doses and coarse grinds while maintaining hermetic seal integrity. You might find that standard 10g drip bag machines struggle with the physical volume of larger doses, leading to ruptured filters or messy seals. This technical challenge requires a specific approach to cold brew coffee packaging that emphasizes ultrasonic sealing and precision dosing. By upgrading your equipment standards, you can move from small-scale manual filling to high-speed industrial production without sacrificing quality.

Why are 15g-20g large filters essential for cold brew?

Large 15g-20g filters are essential because cold brew requires a much higher coffee-to-water ratio and a longer immersion time than hot coffee. Standard 10g bags simply do not provide enough contact surface or volume to produce the bold, concentrated flavor profile that your customers expect from cold brew coffee packaging. Using a larger filter allows for the necessary expansion of grounds as they saturate, ensuring a consistent extraction throughout the 12-to-24-hour brewing cycle.

Do larger filters change the extraction dynamics?

Yes, larger filters fundamentally alter the extraction by providing more room for water to circulate around the coarse grounds. If you pack 20g of coffee into a bag designed for 10g, the grounds become too compressed, preventing water from penetrating the center of the dose.

The best part?

- Increased surface area prevents “dry pockets” in the filter.

- Better water flow leads to a smoother, less acidic cup.

- High-capacity bags support the “cold-and-slow” immersion method perfectly.

When you use a 20g filter, you are giving the coffee room to breathe and release its full aromatic potential. Key Takeaway: Switching to larger filters is the only way to achieve the professional-grade concentration required for premium cold brew products.

| Filter Size | Recommended Water Volume | Extraction Quality | Ideal For |

|---|---|---|---|

| 10g (Standard) | 150ml – 180ml | Weak/Diluted | Hot Drip |

| 15g (Large) | 200ml – 250ml | Balanced | Single-Serve Cold Brew |

| 20g (XL) | 300ml+ | Concentrated | Cold Brew Pouches |

The data shows that 20g filters provide the highest extraction quality for cold brew enthusiasts who demand a rich concentrate.

What technical adjustments are needed for coarse grinds?

Adjusting for coarse grinds requires a specialized auger filler or volumetric cup system designed to handle larger particles without clogging or causing weight fluctuations. In the world of cold brew coffee packaging, the consistency of your grind size dictates the flow rate during the filling process. If your machine isn’t calibrated for the “rocky” texture of cold brew grounds, you will face significant downtime due to mechanical jams or inaccurate dosing.

Why does grind size impact machine calibration?

Coarse grounds occupy more volume than fine powder, meaning your dosing chambers must be physically larger to accommodate the same weight. If your current drip coffee bag machine was built for espresso-fine grinds, the hopper and discharge chutes might be too narrow.

Think about it:

- Coarser particles have different friction coefficients.

- Volumetric cups need deeper settings for 20g of coarse coffee.

- Auger screws must have wider flights to move large particles smoothly.

Look: you can’t just throw coarse grounds into a standard machine and expect perfection. Key Takeaway: Technical recalibration of the dosing unit is mandatory to ensure that every 20g bag contains exactly 20g of coffee.

| Component | Fine Grind Setting | Coarse Grind Adjustment | Technical Benefit |

|---|---|---|---|

| Dosing Head | Narrow/Shallow | Deep/Wide | Prevents particle bridging |

| Auger Screw | High RPM / Fine Pitch | Lower RPM / Wide Pitch | Maintains particle integrity |

| Vibration | Low Intensity | High Intensity | Ensures even settling in bags |

Larger particles require wider mechanical paths to ensure that the heavy 20g dose settles quickly and evenly before sealing.

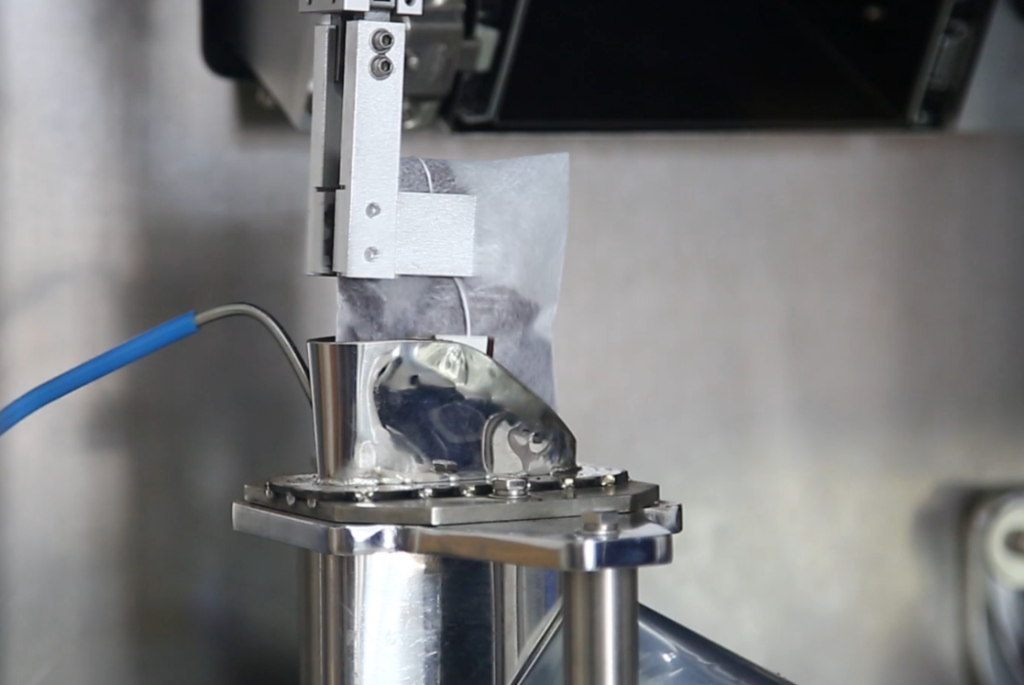

How does ultrasonic sealing ensure cold brew bag integrity?

Ultrasonic sealing ensures bag integrity by using high-frequency vibrations to create a molecular bond, which is much stronger than traditional heat sealing for heavy 20g loads. This technology is critical for cold brew coffee packaging because it can seal through dust and oils that often contaminate the seal area. When you are dealing with a 20g dose, the weight of the coffee exerts significant pressure on the bottom seal during the filling process, and ultrasonic welds are the only ones that consistently hold.

Is ultrasonic better than heat sealing for large bags?

Ultrasonic sealing is vastly superior for larger bags because it doesn’t rely on thermal conduction, which can weaken the surrounding filter material. Heat sealing often leaves “hot spots” that become brittle, leading to bags that burst when submerged in water for 24 hours.

Here is the deal:

- Ultrasonic seals are instantaneous and require no warm-up time.

- The bond is 99.9% reliable even with heavy 20g fills.

- Cold sealing technology preserves the volatile oils in your premium coffee.

But that’s not all. Ultrasonic sealing also allows for a narrower seal margin, which gives you more internal volume for the coffee to expand. Key Takeaway: If you are moving to 15g-20g filters, ultrasonic sealing from newideapack is a non-negotiable requirement for product safety.

| Feature | Traditional Heat Seal | Ultrasonic Seal | Impact on 20g Bags |

|---|---|---|---|

| Seal Strength | Variable (Low) | Extremely High | No bursting during soaking |

| Contamination | Fails with dust/oil | Seals through dust | Higher production uptime |

| Material Integrity | Weakened by heat | Perfectly preserved | Professional look and feel |

By eliminating the thermal stress on the filter fabric, ultrasonic technology ensures that the bag remains a perfect vessel for long-term immersion.

Which machine features handle the weight of 20g filters?

Machine features like reinforced film pulling systems and heavy-duty bag support clamps are required to handle the increased physical weight of 20g filters. In cold brew coffee packaging, the jump from 10g to 20g isn’t just a 100% weight increase; it also increases the momentum of the bag as it moves through the line. You need a machine with a robust mechanical structure that prevents the filter from sagging or stretching under its own weight during the sealing cycle.

Do you need a specific type of film pulling?

Yes, you need a servo-driven pulling system that can handle the increased inertia of a heavy bag without slipping. Standard friction-based pullers might fail when the bag reaches its maximum weight capacity, leading to inconsistent bag lengths.

Look:

- Servo motors provide the torque needed for heavy loads.

- Vacuum-assisted pull belts ensure a non-slip grip on the filter.

- Reinforced bag-bottom supports prevent the seal from stretching.

The best part? Modern machines from newideapack are built with these heavy-duty components as standard. Key Takeaway: Ensure your drip coffee bag machine has the mechanical “muscle” to move 20g doses without losing precision.

| Machine Part | Standard Capacity | Heavy-Duty Requirement | Result |

|---|---|---|---|

| Pulling Motor | Stepper Motor | High-Torque Servo | Precise bag length |

| Bag Support | Air-jet only | Mechanical “Bottom-Up” Support | Perfect seal geometry |

| Tension Control | Manual spring | Automatic Electronic Control | No filter deformation |

Advanced servo controls are the secret to maintaining high speeds when your product weight doubles.

Why is nitrogen flushing critical for large cold brew bags?

Nitrogen flushing is critical for large cold brew bags because the increased surface area of the 20g dose makes the coffee highly susceptible to rapid oxidation. Effective cold brew coffee packaging must achieve oxygen levels below 1.0% to ensure that the delicate chocolate and nutty notes of your cold brew don’t turn sour. Because cold brew grounds are coarse-ground, they have larger “air pockets” within the bag that must be purged of oxygen to extend shelf life to 12 months or more.

How does the larger volume affect nitrogen efficiency?

The larger 20g volume requires a more aggressive nitrogen injection strategy to displace the air trapped deep within the coarse grounds. Simply blowing nitrogen over the top of the bag isn’t enough; you need a system that injects the gas directly into the filter before the final seal.

Think about it:

- Large pores in coarse coffee hold a lot of “stale” air.

- Dual-stage flushing ensures oxygen is pushed out from the bottom up.

- A nitrogen-rich environment prevents the rancidity of natural coffee oils.

But wait, there’s more. The quality of your drip coffee bag machine determines how well it maintains that nitrogen blanket during the high-speed transition to the outer envelope. Key Takeaway: Without high-purity nitrogen flushing, your premium 20g cold brew bags will lose their freshness within weeks.

| Freshness Factor | No Nitrogen | Single Flush | Dual-Stage Nitrogen |

|---|---|---|---|

| Residual Oxygen | 20.9% | 2.5% – 5.0% | < 1.0% |

| Flavor Stability | 2-4 Weeks | 3-6 Months | 12-24 Months |

| Aroma Retention | Poor | Moderate | Excellent |

Displacing oxygen at the source is the only way to guarantee the long-term flavor stability of large-dose cold brew products.

What filter materials work best for 15g-20g doses?

The best filter materials for 15g-20g doses are high-gsm (grams per square meter) non-woven fabrics or PLA (Polylactic Acid) meshes that offer high tensile strength. In cold brew coffee packaging, the material must be porous enough for long-term immersion but strong enough to hold a heavy, wet dose without tearing. If you use standard thin filter paper designed for 8g of hot coffee, the weight of the 20g soaked grounds will almost certainly cause the bag to fail when the customer tries to remove it.

Is eco-friendly material strong enough for 20g?

Modern PLA mesh is actually stronger than many traditional synthetic filters and provides excellent clarity for the brewing process. If you want a premium look, PLA allows the customer to see the quality of the coarse grounds while ensuring the bag stays intact for a 24-hour soak.

Look:

- High-gsm non-woven fabric prevents “fine” migration into the cup.

- PLA mesh offers a sustainable, biodegradable option for high-end brands.

- Reinforced ultrasonic-compatible materials are a must for newideapack machines.

The best part?

- You get a sediment-free cup every time.

- The materials are fully compostable in industrial facilities.

- Customers love the premium, fabric-like feel of high-quality filters.

Key Takeaway: Investing in thicker, high-quality filter material is the best insurance policy against product failure and negative customer reviews.

| Material Type | Strength Rating | Clarity | Sustainability |

|---|---|---|---|

| Standard Paper | Low | Poor | High |

| Non-Woven Fabric | High | Good | Moderate |

| PLA Mesh | Extremely High | Excellent | Extremely High |

Choosing a high-tensile material like PLA mesh ensures your 20g bag remains durable even after hours of submersion.

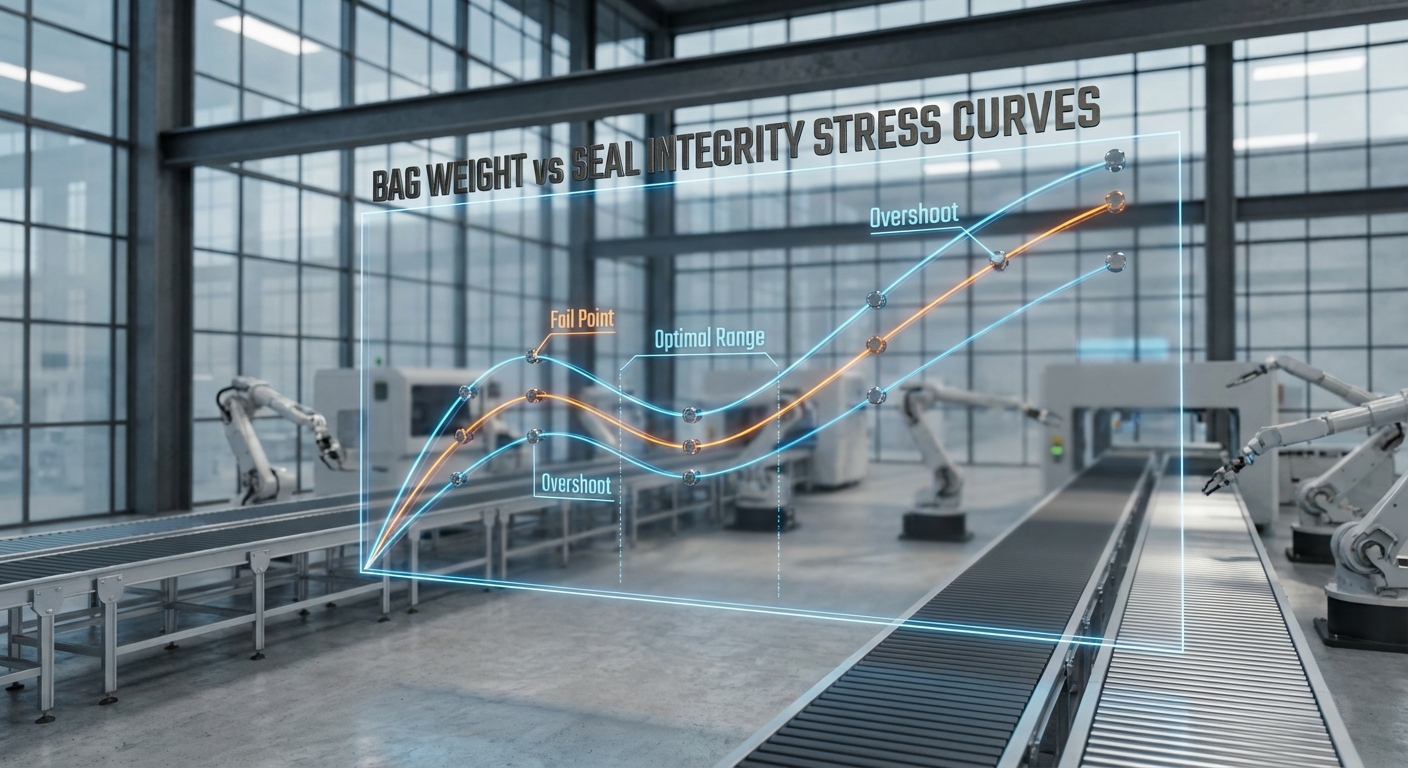

How do automated lines prevent pouch leakage at high speeds?

Automated lines prevent leakage by using high-precision sensors to verify the seal integrity and weight of every single bag at speeds up to 50 bags per minute. For cold brew coffee packaging, leakage is usually caused by “product in seal”—where coffee grounds get trapped in the sealing area. High-speed lines from newideapack use specialized “stripper” plates that clear the seal area of any debris before the ultrasonic head engages.

Can sensors detect a bad seal before it’s too late?

Yes, advanced packaging lines use vision systems and pressure sensors to detect even microscopic gaps in the seal. If a 20g bag is improperly sealed, the system can automatically reject it before it is placed into the outer envelope.

Think about it:

- Vision systems check for perfect seal alignment.

- Pressure testers verify that the bond can hold a 20g load.

- Automatic reject gates remove “leakers” without stopping the line.

But wait, there’s more. Integrating a drip coffee bag machine with a secondary check-weigher ensures that every bag meets your strict quality standards. Key Takeaway: Automation isn’t just about speed; it’s about the consistent quality control that human operators can’t provide at scale.

| Automation Feature | Function | Benefit for 20g Bags |

|---|---|---|

| Seal Strippers | Clears debris from seal area | Prevents chronic leakage |

| Vision Inspection | Optical seal verification | Eliminates visual defects |

| Auto-Reject | Removes sub-standard bags | Guarantees 100% shelf readiness |

High-speed automation ensures that your heavy-duty cold brew bags are produced with zero defects, protecting your brand reputation.

Can standard drip bag machines be upgraded for larger sizes?

Standard drip bag machines can sometimes be upgraded with “large format” kits, but for consistent 20g production, a purpose-built large-filter machine is highly recommended. While you can swap out the forming shoulder and dosing cups on some cold brew coffee packaging lines, the underlying frame and motors must be capable of handling the increased stress. Trying to push a 10g machine to produce 20g bags often leads to premature motor failure and inconsistent seal quality.

What are the limits of “standard” hardware?

Standard hardware is typically optimized for a specific range, and pushing past 15g often exceeds the “sweet spot” of the machine’s timing and torque.

Look:

- Standard heaters may not penetrate thicker 20g filter material.

- Small air cylinders may lack the “clamp force” for wide seals.

- Hopper capacities on small machines require too-frequent refilling.

The best part? newideapack offers machines specifically engineered for the 15g-35g range, eliminating the need for risky aftermarket hacks. Key Takeaway: If you plan to make 20g cold brew bags a core part of your business, invest in a machine designed for that specific weight class.

| Machine Capability | Standard Model (Up to 12g) | Cold Brew Model (Up to 30g) | Upgrade Feasibility |

|---|---|---|---|

| Frame Strength | Lightweight | Reinforced Steel | Difficult |

| Dosing Volume | Max 150cc | Max 500cc | Possible (Cup swap) |

| Seal Width | 3mm – 5mm | 5mm – 10mm | Requires Head Swap |

While some components can be swapped, the core mechanical architecture of a cold brew machine is built for higher durability.

What are the outer envelope requirements for large cold brew bags?

Outer envelopes for large cold brew bags require high-barrier materials like aluminum-laminated foil or metallized PET to protect the 20g dose from moisture and oxygen. In the realm of cold brew coffee packaging, the outer envelope is your second line of defense. Because the inner filter is highly porous, the outer pouch must be 100% airtight and offer superior light-blocking properties to prevent the coffee oils from going rancid.

Why is pouch sizing more complex for 20g?

A 20g dose creates a significantly “fatter” inner bag, meaning your outer envelope must have a larger footprint or a gusseted bottom to prevent the inner bag from being crushed. If the envelope is too tight, the drip coffee bag machine will struggle to insert the filter, leading to jams and torn packaging.

Here is the deal:

- Outer pouches should be roughly 20% larger than standard sizes.

- Matte finishes provide a premium “craft” feel for specialty brands.

- Tear notches must be precisely placed for easy consumer access.

Look: a premium product needs premium housing. Key Takeaway: Don’t skimp on the outer envelope; it’s what keeps your expensive 20g dose fresh and makes the first impression on your customer.

| Envelope Layer | Material Choice | Purpose |

|---|---|---|

| Outer Layer | BOPP / Matte PET | Printability and Aesthetics |

| Barrier Layer | AL (Foil) / VMPET | Oxygen and Light Blockage |

| Inner Layer | PE (Polyethylene) | High-Strength Sealing |

A three-layer laminate is the industry gold standard for maintaining the “fresh-roasted” aroma of large cold brew bags.

How do you maintain quality control for heavy drip bags?

Maintaining quality control involves a combination of automated check-weighing and manual “burst tests” to ensure the 20g dose is both accurate and securely contained. In cold brew coffee packaging, even a 0.5g variance can affect the final flavor of the concentrate, making precision dosing a top priority. You should implement a protocol where a percentage of bags from every batch are submerged in water and agitated to simulate real-world brewing conditions.

What are the most common failure points?

The most common failure point for 20g bags is the bottom seal “zipping” open under the weight of wet coffee grounds.

Think about it:

- Wet grounds weigh three times more than dry grounds.

- Standard adhesive seals can dissolve during long immersion.

- Vibration during shipping can cause coarse grounds to “saw” through thin filters.

Look:

- Check-weighers should have a ±0.2g tolerance.

- Ultrasonic seal patterns should be checked for “voids.”

- Moisture meters should verify that the incoming beans are perfectly dry.

The best part? By following these strict QC steps, you can virtually eliminate customer complaints. Key Takeaway: High-quality cold brew coffee packaging requires high-quality testing; never assume the machine is perfect without verifying the output.

| QC Test | Method | Pass Criteria |

|---|---|---|

| Weight Check | Inline Check-weigher | ± 0.2g Accuracy |

| Leak Test | Vacuum Chamber | No bubbles for 60 seconds |

| Strength Test | 24-Hour Soak | No seal separation or tearing |

Rigorous testing ensures that your 20g cold brew bags perform flawlessly in the consumer’s kitchen.

Conclusion

Scaling your cold brew production to include 15g-20g large filters is a powerful way to meet the growing demand for high-quality, convenient coffee. By understanding the tech requirements—from ultrasonic sealing and coarse-grind dosing to nitrogen flushing and high-barrier envelopes—you can avoid the common pitfalls of small-scale production. At newideapack, we specialize in providing the heavy-duty machinery and technical expertise needed to turn your large-format cold brew dreams into a high-speed reality. If you are ready to upgrade your operations and dominate the cold brew market, contact us today to discuss a custom solution for your brand.

FAQ

Can I use my existing 10g machine for 20g bags?

It is unlikely without major modifications. Most standard machines have dosing cups and sealing jaws that are physically too small to accommodate the volume of a 20g coarse grind.

What’s the best material for eco-friendly cold brew bags?

PLA mesh is the best choice. It provides the highest strength and clarity while being fully industrially compostable, which aligns with the values of many cold brew drinkers.

How do I know if my nitrogen flushing is working?

You must use an oxygen analyzer. If your residual oxygen levels are above 1.5%, your coffee will oxidize quickly, so you need to adjust your flow rates or seal timing.

How do I prevent the bag from bursting during a 24-hour soak?

You should use ultrasonic sealing. Unlike heat sealing, ultrasonic welds create a molecular bond that does not weaken when exposed to long-term moisture.

Can I package cold brew concentrate in these bags?

No, these bags are for dry grounds. These filters are designed for “brew-at-home” convenience, allowing the customer to create their own fresh concentrate.

Do you have a custom 20g Cold Brew project?

Don’t risk your production on machine downtime. Contact Newidea Pack today for a Free Machine Feasibility Study and see how our ultrasonic technology handles your specific coffee blend.