Ultrasonic Coffee Packaging vs. Heat Sealing: 7 Reasons It’s Better for Drip Bags

Ultrasonic sealing is the superior choice for drip coffee bags because it provides a tighter seal without damaging the delicate coffee aroma through excessive heat. Many roasters struggle with inconsistent seal integrity and flavor loss when using traditional heat methods. This leads to customer dissatisfaction and increased product returns. By adopting ultrasonic coffee packaging, you can ensure every bag is perfectly sealed while maintaining the premium quality of your grounds.

Why is seal integrity critical for drip coffee bags?

Seal integrity ensures that the ground coffee remains fresh and protected from oxygen and moisture. When using ultrasonic coffee packaging, the bond is formed at the molecular level, creating a barrier that is far more reliable than traditional thermal welds. This precision is vital for the thin, non-woven materials typically used in drip bags.

Think about it: a single pinhole leak can ruin an entire batch of premium coffee. Ultrasonic technology eliminates this risk by vibrating the material to create heat internally rather than applying it externally.

Benefits of molecular bonding

Ultrasonic vibrations create a uniform seal across the entire surface of the material. This method is particularly effective when coffee dust is present in the seal area, as the vibrations push particles out of the way.

- Enhanced shelf life

- Consistent seal strength

- Reduced leak rates

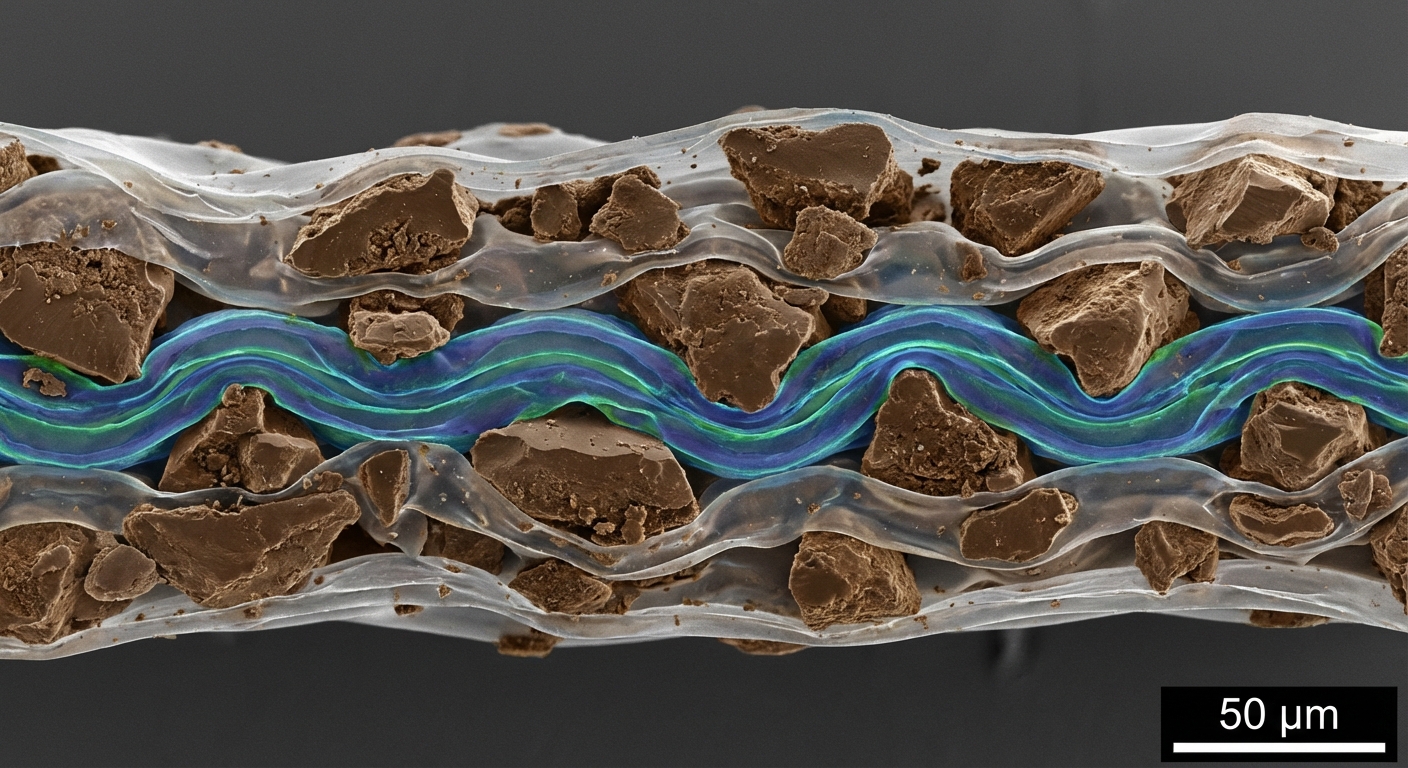

Microscopic seal comparison

The difference between sealing methods is most apparent under magnification. While heat sealing can cause thinning of the film, ultrasonic sealing maintains material thickness.

| Feature | Heat Sealing | Ultrasonic Sealing |

|---|---|---|

| Seal Mechanism | External Heat | Internal Vibration |

| Pinhole Risk | Higher | Negligible |

| Dust Tolerance | Low | High |

Key Takeaway: Ultrasonic sealing provides superior protection against leaks and oxidation, ensuring your coffee stays fresh from the factory to the cup.

What are the financial benefits of ultrasonic coffee packaging?

Ultrasonic coffee packaging offers a higher return on investment by significantly reducing energy consumption and material waste. While the initial setup cost for ultrasonic coffee packaging may be higher, the long-term operational savings are substantial. You will see a noticeable decrease in your monthly utility bills and raw material expenses.

Here is the kicker: the energy is only consumed during the actual sealing millisecond. Unlike heat bars that must remain hot all day, ultrasonic horns stay cool until they are activated.

Energy efficiency metrics

Conventional heat sealers require constant power to maintain high temperatures on the sealing bars. Ultrasonic systems operate on-demand, which can reduce energy usage by up to 75%.

- Low standby power

- Zero warm-up time

- Reduced HVAC load

Long-term ROI factors

Investing in modern technology stabilizes your production costs over time. The reduction in rejected bags alone can pay for the equipment upgrade within the first year of operation.

| Financial Metric | Heat Sealing | Ultrasonic Sealing |

|---|---|---|

| Energy Usage | Constant/High | On-demand/Low |

| Material Waste | 3-5% | <1% |

| Annual ROI | Standard | Accelerated |

Key Takeaway: Switching to ultrasonic technology is a strategic financial move that lowers overhead and boosts your bottom line through efficiency.

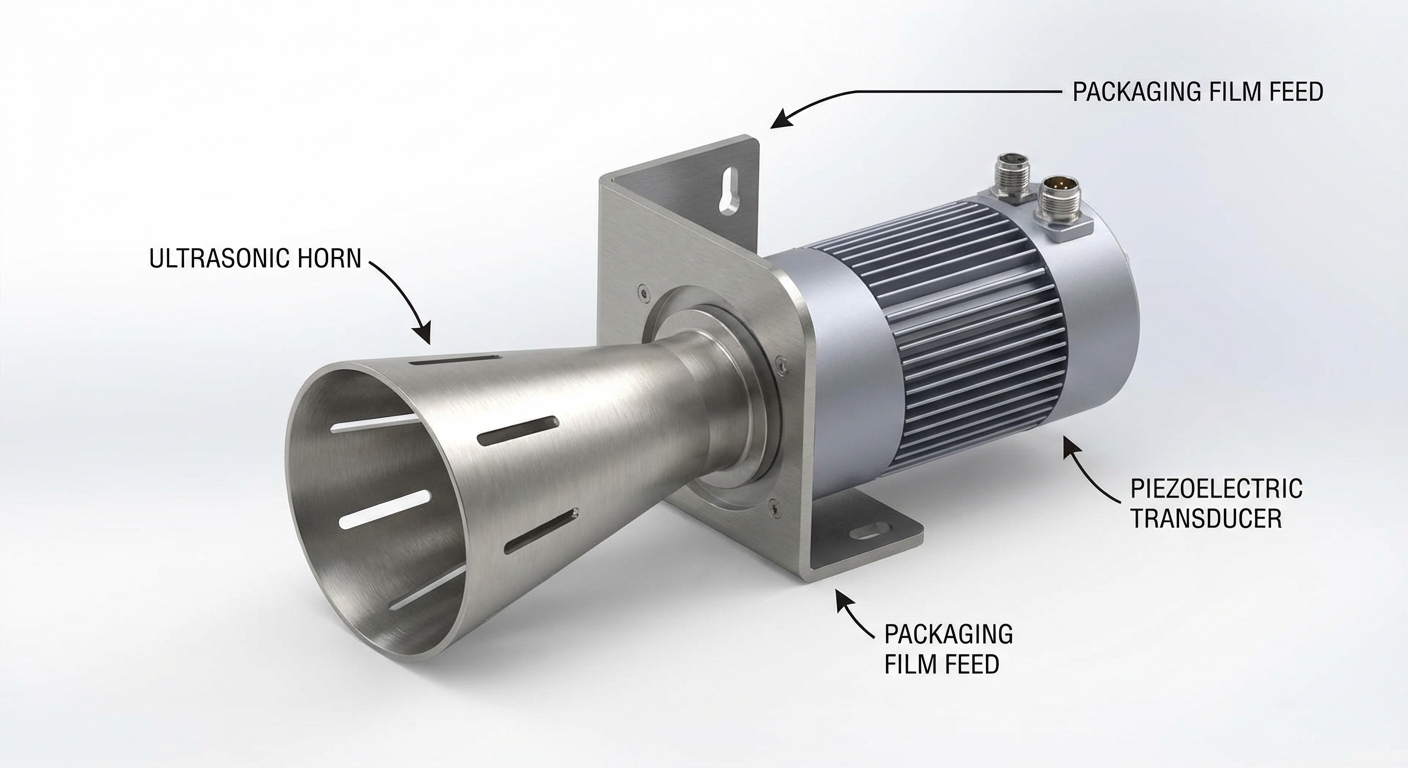

How does the ultrasonic horn improve packaging precision?

The ultrasonic horn improves precision by focusing acoustic energy exactly where the seal needs to be formed. In ultrasonic coffee packaging, the horn and anvil work together to compress the material and trigger a localized melt. This prevents the “heat spread” that often causes wrinkling or warping in standard thermal sealing.

It gets better: the precision of the horn allows for much narrower seal margins. This might seem minor, but it allows you to fit more product into a smaller bag or save on total film length.

Mechanical precision and control

Modern transducers convert electrical energy into mechanical vibrations with extreme accuracy. This ensures that every single bag in a 10,000-unit run is identical in seal quality.

- Precise pressure control

- Narrower seal widths

- Automated frequency tuning

Component durability

The ultrasonic horn is designed for high-frequency operation without the wear and tear associated with scorched heat bars. This leads to more uptime and fewer mid-shift adjustments.

| Component | Function | Advantage |

|---|---|---|

| Transducer | Converts Energy | High Efficiency |

| Horn (Sonotrode) | Delivers Vibration | Focused Sealing |

| Anvil | Provides Resistance | Consistent Pattern |

Key Takeaway: The focused energy of the ultrasonic horn allows for tighter tolerances and higher aesthetic quality in your drip bag presentation.

How does heat sealing compare to ultrasonic sealing in practice?

Heat sealing relies on thermal conduction, whereas ultrasonic coffee packaging uses friction-induced internal heat. While heat sealing is a proven technology for many industries, it often struggles with the heat-sensitive non-woven fabrics used for coffee drip bags. Excess heat can cause the material to become brittle or lose its filtering properties.

But that’s not all—heat sealing often requires a larger footprint on the bag to ensure a secure bond. Ultrasonic technology creates a stronger bond in a fraction of the space.

Operational differences

In a heat-sealing setup, the machine must reach a specific temperature before production begins. Ultrasonic systems are ready to go the moment you flip the switch, saving valuable production time.

- Faster start-up times

- No cooling stations needed

- Safer for operators

Performance under pressure

When running at high speeds, heat sealing often struggles to transfer enough thermal energy to the film. Ultrasonic sealing remains consistent regardless of the cycle speed.

| Performance | Heat Sealing | Ultrasonic Sealing |

|---|---|---|

| Start-up Time | 15-30 Minutes | Instant |

| Thermal Stress | High | Low/Zero |

| Safety Profile | Burn Risk | Cool to Touch |

Key Takeaway: While heat sealing is traditional, ultrasonic technology offers the speed and safety required for modern, high-volume coffee production.

Can the aroma of the coffee be preserved better?

The aroma is preserved better with ultrasonic coffee packaging because the sealing process does not raise the temperature of the coffee grounds. Heat sealing can transmit residual warmth into the bag, which accelerates the release of volatile oils and gases. This premature degassing results in a stale scent when the consumer finally opens the package.

The best part? You can seal through nitrogen-flushed environments without worrying about heat affecting the gas density. This ensures the protective atmosphere remains stable and effective.

Aroma protection mechanisms

Ground coffee is highly sensitive to temperature fluctuations. By keeping the sealing area cool, you protect the complex chemical compounds that define your coffee’s flavor profile.

- Cold-seal technology

- Preserved volatile oils

- Better nitrogen retention

Flavor stability over time

Maintaining a low-temperature environment during packaging extends the “roast-fresh” taste of the product. Consumers notice the difference in quality the moment they brew.

| Quality Factor | Heat Sealing Impact | Ultrasonic Impact |

|---|---|---|

| Volatile Oils | Potential Degradation | Fully Preserved |

| Degassing | Accelerated | Controlled |

| Consumer Scent | Average | High Intensity |

Key Takeaway: Ultrasonic sealing acts as a “cold-process” solution that locks in the premium aroma your customers expect from specialty coffee.

Is maintenance easier on ultrasonic coffee machines?

Maintenance is generally easier and less frequent for ultrasonic coffee packaging equipment. Traditional heat bars suffer from “carbonization,” where plastic and coffee dust burn onto the metal surface. This requires frequent cleaning and abrasive scrubbing that can damage the sealing profile over time.

You might be wondering: what about the complexity of the electronics? While advanced, modern ultrasonic generators are modular and often feature self-diagnostic tools to simplify troubleshooting.

Cleaning and upkeep

Since the ultrasonic horn remains cool, there is no melting of film onto the tool. This eliminates the need for the harsh chemicals often used to clean traditional heat sealers.

- No carbon buildup

- Fewer replacement parts

- Self-cleaning vibrations

Tooling longevity

Ultrasonic components are made from high-grade titanium or hardened steel. They are designed to withstand millions of cycles without the warping caused by constant thermal expansion.

| Maintenance Task | Heat Sealers | Ultrasonic Sealers |

|---|---|---|

| Daily Cleaning | High (Scrubbing) | Low (Wiping) |

| Part Replacement | Heater Bands/Wires | Horn (Long Life) |

| Troubleshooting | Manual/Thermal | Digital/Automatic |

Key Takeaway: Lower maintenance requirements mean more “up-time” for your production line and less frustration for your technical staff.

How much material waste can you actually save?

You can save up to 15% in material costs by utilizing the narrow seals possible with ultrasonic coffee packaging. Heat seals usually require a width of 5mm to 10mm to ensure a solid bond. Ultrasonic seals can be as narrow as 1mm to 2mm while providing the same or better strength.

In other words, you are using less film for every single bag produced. Over a year of high-volume production, these millimeters translate into miles of saved packaging material.

Film optimization

Using less material per bag isn’t just about cost; it’s also about sustainability. Reducing your plastic or non-woven footprint aligns with modern eco-friendly business goals.

- Minimal seal overlap

- Reduced trim waste

- Optimized bag dimensions

Reducing reject rates

Misaligned heat seals often result in “leakers” that must be discarded. The precision of ultrasonic technology ensures a perfect seal every time, reducing the pile of wasted products.

| Waste Category | Heat Sealing | Ultrasonic Sealing |

|---|---|---|

| Seal Width | 8mm Average | 2mm Average |

| Scrap Rate | 2-4% | <0.5% |

| Film Savings | Baseline | 10-15% Higher |

Key Takeaway: Ultrasonic technology allows you to do more with less, directly contributing to both profitability and environmental sustainability.

Are production speeds higher with ultrasonic systems?

Production speeds are significantly higher with ultrasonic coffee packaging because the sealing time is measured in milliseconds. In a traditional heat system, you must wait for the heat to penetrate through the film layers. Ultrasonic energy creates an instant bond, allowing the machine to cycle faster without compromising seal quality.

Make no mistake: if you are looking to scale your business, speed is the most critical factor. Modern ultrasonic drip bag machines can easily reach speeds of 50 to 90 bags per minute.

Throughput and efficiency

The “dwell time” required for a seal is the primary bottleneck in packaging. Reducing this time allows the mechanical components of the machine to run at their maximum rated speed.

- Shorter dwell times

- Continuous motion support

- High-speed bag cutting

Scaling your operations

As your brand grows, your equipment must keep up. Ultrasonic systems are designed for 24/7 high-speed operation, making them the standard for industrial-scale coffee roasters.

| Machine Capability | Standard Heat | Newideapack Ultrasonic |

|---|---|---|

| Bags Per Minute | 30 – 45 | 60 – 100 |

| Seal Reliability | Speed Dependent | Speed Independent |

| Daily Output | ~20,000 Units | ~45,000+ Units |

Key Takeaway: High-speed ultrasonic sealing removes the production bottleneck, allowing you to fulfill larger orders with shorter lead times.

Premium brands prefer the ultrasonic look because it results in a much cleaner, more professional finish for ultrasonic coffee packaging. Heat sealing often leaves behind unsightly burn marks, melted edges, or “heat wrinkles” on the bag. These small defects can detract from the high-end aesthetic that specialty coffee consumers expect.

Let’s dive in: in the B2B world, packaging is your first handshake with the customer. A sleek, perfectly flat seal signals quality and attention to detail before the coffee is even brewed.

Aesthetic superiority

Ultrasonic seals are almost invisible or can be patterned with high-precision textures. This level of customization allows your branding and logo to stand out without distraction.

- No “burn” discoloration

- Flat, wrinkle-free seams

- Custom seal patterns

Consumer perception

When a customer sees a crisp, clean drip bag, they perceive the product as being of higher value. This allows premium roasters to justify higher price points in competitive markets.

| Aesthetic Feature | Heat Sealed Bag | Ultrasonic Bag |

|---|---|---|

| Surface Texture | Often Distorted | Perfectly Smooth |

| Edge Quality | Rough/Melted | Sharp/Defined |

| Brand Image | Budget/Standard | Premium/Luxury |

Key Takeaway: The visual quality of an ultrasonic seal reinforces your brand’s commitment to excellence and premium product standards.

Why Top Roasters Choose Ultrasonic Coffee Packaging Over Heat Sealing in 2026?

1.Superior Aroma Preservation (Cold Sealing)

2.Molecular Seal Integrity (Zero Leaks)

3.Significant Reduction in Material Waste

4.High-Speed Production Efficiency

5.Energy Savings & Sustainability

6.Precision Sealing Through Powder/Dust

7.Premium Aesthetic for Specialty Branding

Which Newideapack machine is right for your facility?

Choosing the right machine depends on your current production volume and your goals for ultrasonic coffee packaging. Newideapack offers a range of solutions, from compact units for boutique roasters to fully automated lines for global distributors. Our technicians ensure that every machine is calibrated to your specific coffee grind and bag material.

The result? You get a turnkey solution that integrates seamlessly into your existing workflow. Whether you need nitrogen flushing or high-speed outer envelope packing, we have the right configuration.

Selection criteria

Consider your daily output requirements and available floor space. Our modular designs allow you to start small and add features like automatic counting or cartoning as you grow.

- Daily bag volume

- Material specifications

- Space constraints

Expert support and calibration

Every Newideapack machine comes with professional support to ensure your ultrasonic parameters are optimized. We help you find the perfect balance between speed, pressure, and frequency.

| Machine Model | Best For | Key Feature |

|---|---|---|

| ND-C60 | Medium Roasters | Versatile & Compact |

| ND-C80Pro | High Volume | Fully Automated |

| ATB-DC30 | Entry Level | Easy Operation |

Key Takeaway: Newideapack provides tailored ultrasonic solutions that grow with your business, ensuring you always have the most efficient sealing technology.

Selecting the right sealing technology is the difference between a standard product and a market-leading brand. At Newideapack, we believe that ultrasonic technology is the future of the coffee industry. By prioritizing aroma preservation, material efficiency, and production speed, you position your business for long-term success.

FAQ

Can I use ultrasonic sealing on compostable drip bags?

Yes, ultrasonic technology is highly effective on many compostable materials because it creates a bond without the high temperatures that can degrade bio-plastics.

Is ultrasonic sealing louder than heat sealing?

While the vibrations are at a high frequency (above human hearing), the mechanical movement of the machine creates a similar noise level to standard packaging equipment.

Does ultrasonic coffee packaging require special training?

Basic operation is very similar to heat sealers, though our technicians provide specific training on frequency tuning to ensure optimal performance.

Can I upgrade my existing heat sealer to ultrasonic?

In many cases, the sealing jaw assembly can be retrofitted, though a dedicated Newideapack ultrasonic machine is usually more efficient.

How does nitrogen flushing work with ultrasonic sealing?

The machine injects nitrogen into the bag just before the ultrasonic horn creates the seal, ensuring maximum oxygen displacement and freshness.

Ready to upgrade your production line?

Contact us today to find the perfect packaging solution for your brand.