OUR CORE SERVICES

Complete Packaging Solutions for Every Industry

Tailored services designed to optimize your flexible packaging operations from concept to completion

Consulting & Design Services

Feature: Comprehensive feasibility studies, packaging design consulting, solution engineering, and R&D services for flexible packaging across all industries.

Advantage: Our experts analyze your production requirements, material characteristics, and market demands to design optimal packaging machinery solutions.

Benefit: Minimize investment risks, accelerate time-to-market, and ensure your packaging equipment perfectly aligns with your business goals for maximum ROI.

Customization & Adaptation

Feature: Tailored packaging machinery configurations for your specific materials, bag types, production speeds, and unique product requirements.

Advantage: Precision-engineered VFFS machines and specialized equipment with adjustable parameters to handle diverse product characteristics from powders to granules.

Benefit: Achieve perfect packaging consistency, product protection, and operational flexibility that adapts as your production needs evolve.

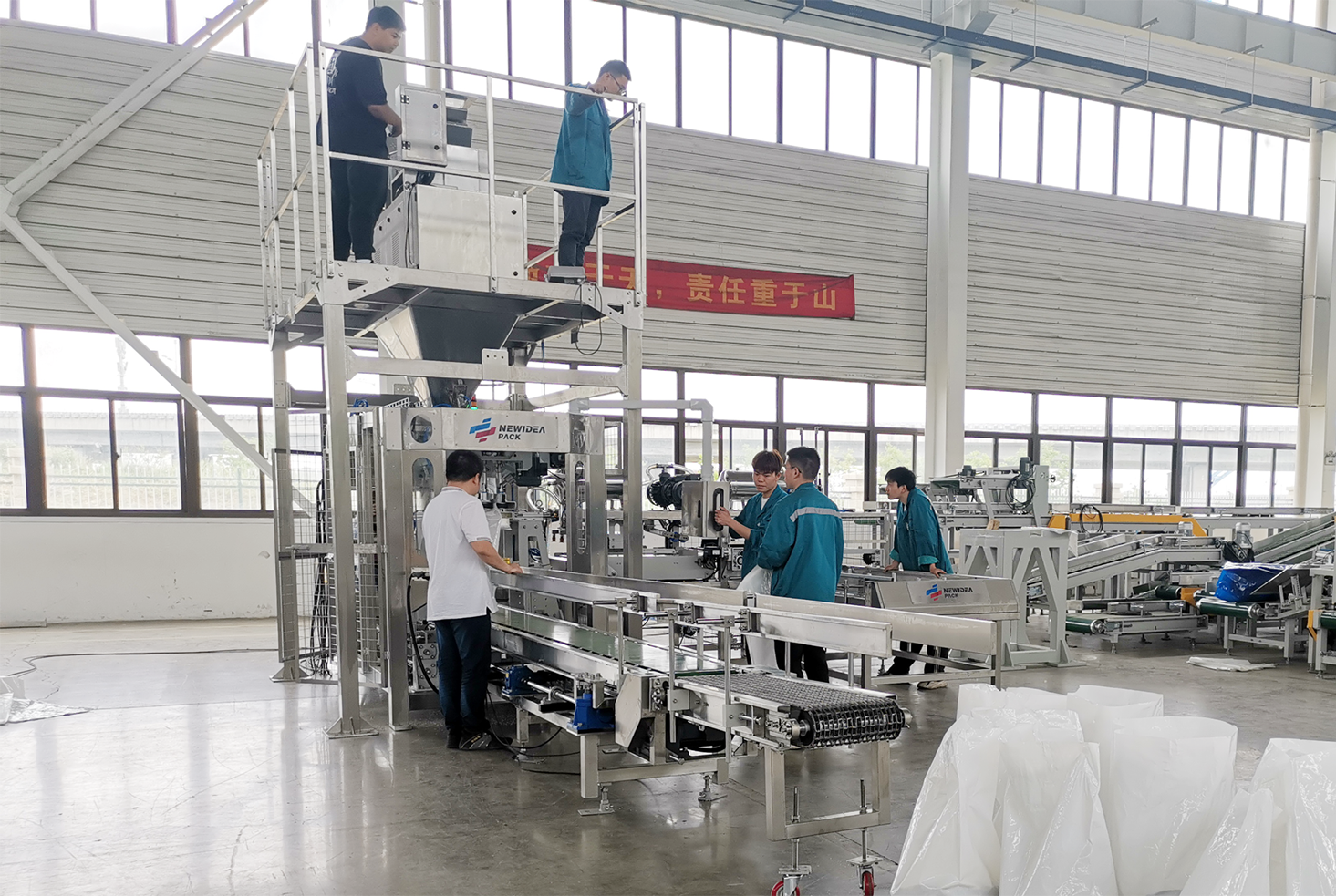

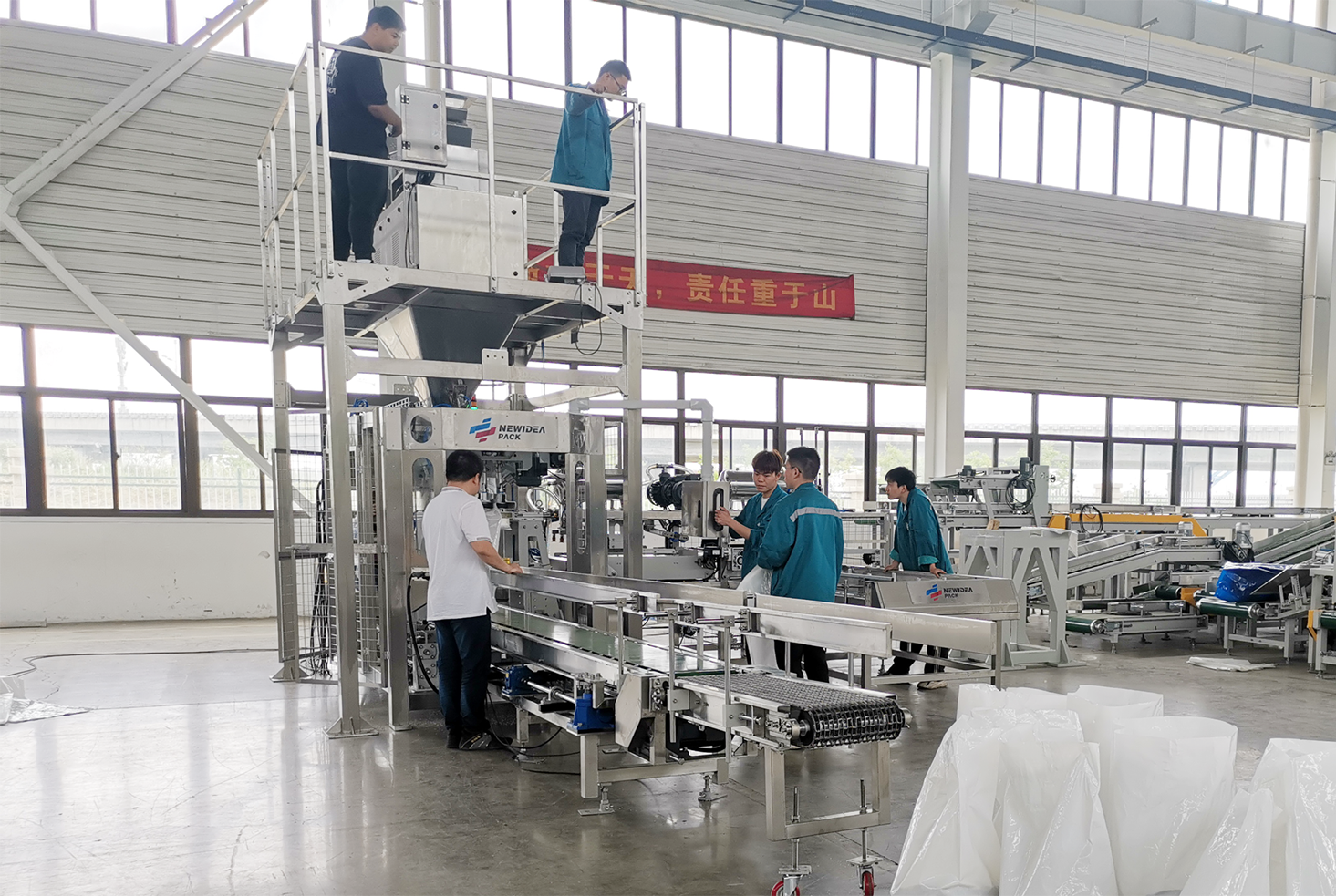

Complete Line Integration

Feature: Seamless integration of vertical form fill seal machines with weighing systems, conveyors, palletizers, and quality control equipment into turnkey production lines.

Advantage: Engineered for smooth workflow and synchronized operation of all packaging equipment, including both new installations and existing production environments.

Benefit: Eliminate production bottlenecks, increase throughput by up to 40%, and achieve automated efficiency that dramatically reduces labor costs.

Ready to optimize your flexible packaging operation?

PACKAGING EQUIPMENT

Advanced Flexible Packaging Machinery

State-of-the-art vertical form fill seal machines and specialized packaging equipment engineered for reliability and precision

Advantage: Advanced PLC control systems with intuitive touchscreen interfaces ensure precise weight accuracy (±0.1g), consistent seal quality, and easy operation for diverse products.

VFFS Packaging Machines

FEATURE: High-speed vertical form fill seal machines with servo-driven control, handling 40-120 bags/minute across multiple industries

Benefit: Maximize production efficiency while minimizing product waste and downtime, delivering cost savings and reliable 24/7 performance that keeps your lines running continuously.

Advantage: Integrated systems create convenient single-serve drip coffee bags with precise portion control, professional presentation, and preserved freshness for premium coffee brands.

Specialized Coffee Solutions

FEATURE: Dedicated drip coffee packaging machines with automated filter bag forming, precise filling, and outer envelope sealing capabilities

Benefit: Capture the high-value specialty coffee market with perfectly packaged products that command premium prices and enhance consumer convenience and satisfaction.

Advantage: Complete turnkey systems handle heavy-duty bulk packaging for flour, rice, pet food, chemicals, and agricultural products with minimal manual intervention.

Open Mouth Bagging Systems

FEATURE: Automated 5-50kg open mouth bagging solutions with integrated weighing, bag filling, sealing, robotic palletizing and stretch wrapping

Benefit: Dramatically reduce labor costs, improve workplace safety, and achieve consistent packaging quality for high-volume bulk product operations.

Advantage: Smart weighing algorithms optimize speed while maintaining exceptional precision (±0.1g-±1g) across chips, nuts, candies, coffee, pet treats, and more.

Precision Weighing Systems

FEATURE: Multi-head weighing technology with 10-14 heads providing ultra-high accuracy for food, snacks, confectionery, and specialty products

Benefit: Ensure regulatory compliance, reduce product giveaway by up to 30%, and protect profit margins on every package while maintaining high throughput speeds.

Discover the perfect packaging machinery for your production needs

COMPREHENSIVE SUPPORT

End-to-End Service & Technical Support

From installation to ongoing maintenance, we're your partner every step of the way

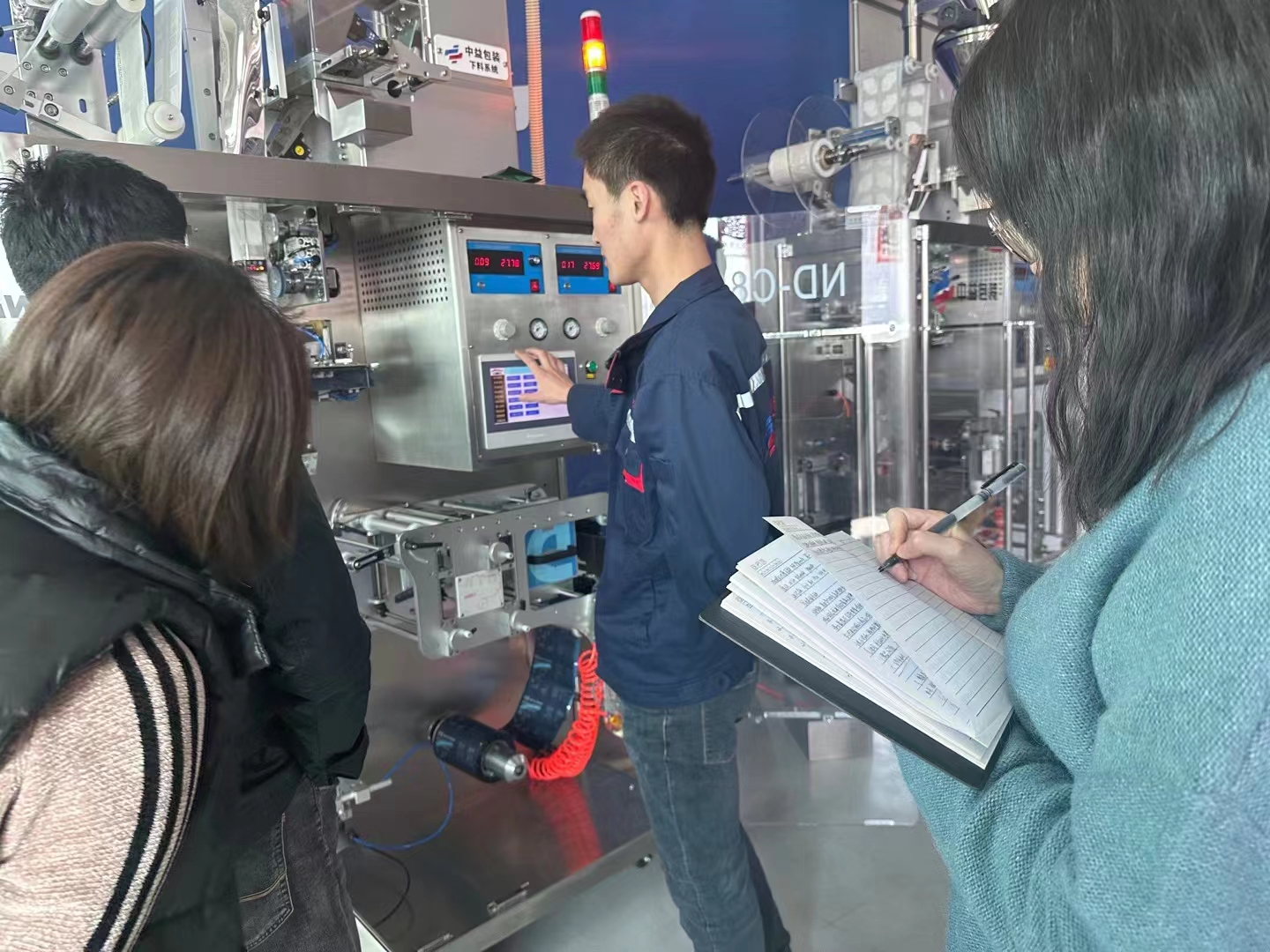

Installation & Commissioning

Expert technicians ensure your packaging machinery is installed correctly, calibrated precisely, and optimized for peak performance from day one of production.

Professional Training

Comprehensive training programs empower your team to operate, maintain, troubleshoot, and optimize flexible packaging equipment for maximum efficiency and safety.

24/7 Technical Support

Round-the-clock remote and on-site technical assistance ensures minimal downtime with immediate expert solutions to any production challenges that arise.

Spare Parts Service

Extensive inventory of genuine spare parts from world-leading brands with fast global delivery, keeping your vertical form fill seal machines running continuously.

Preventive Maintenance

Scheduled maintenance programs maximize equipment lifespan, prevent unexpected failures, and maintain optimal production efficiency throughout the machine lifecycle.

Retrofit & Modernization

Upgrade existing packaging machinery with latest technology to improve performance, efficiency, and capabilities to meet evolving market demands and standards.

Remote Monitoring

IoT-enabled remote diagnostics and monitoring systems provide real-time production insights and predictive maintenance capabilities for proactive issue resolution.

After-Sales Support

Continuous expert knowledge sharing, productivity optimization guidance, and technical support during production to ensure long-term success and equipment performance.

Ensure uninterrupted production with our comprehensive support services

INDUSTRIES WE SERVE

Flexible Packaging Solutions Across Multiple Industries

Market-proven machines and solutions tailored for diverse sectors worldwide

Food & Beverage

Comprehensive solutions for coffee, snacks, chips, chocolate, confectionery, nuts, spices, flour, rice, and frozen foods in flexible formats that preserve freshness and extend shelf life.

Medical & Health

Specialized packaging for healthcare products including sanitized gel, disinfectants, medical supplies, and pharmaceutical products meeting stringent hygiene and safety standards.

Agriculture & Chemical

Robust machinery and customized solutions for efficient and safe packaging of agricultural products, fertilizers, seeds, chemicals, and industrial materials in various bag sizes.

Pet Food

Professional packaging solutions for pet food and treats from small portion bags to large bulk packaging, ensuring product freshness and convenient handling for pet owners.

Coffee Packaging

Specialized solutions for drip bag coffee, stick pouch instant coffee, pre-made bags, quad-seal bags, and valve bags that preserve coffee freshness and aroma for premium brands.

Open Mouth Bagging

Automated 5-50kg open mouth bagging solutions with robotic palletizing and wrapping for flour, grains, powders, and bulk materials requiring heavy-duty packaging.

Find the perfect packaging solution for your industry

OUR PROCESS

Streamlined Project Implementation

A proven 4-step process ensuring successful deployment of your flexible packaging machinery

Consultation & Assessment

We analyze your products, materials, production volume, packaging requirements, and business objectives to design the optimal flexible packaging solution.

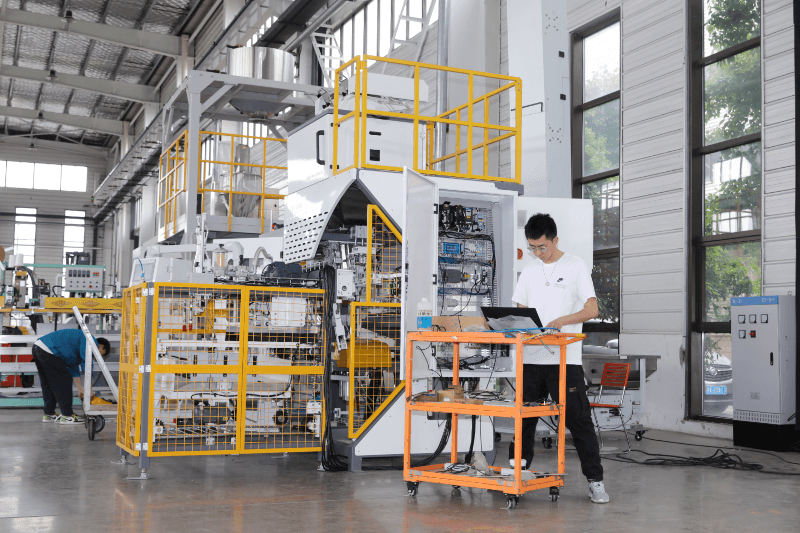

Solution Design

Our engineers develop customized packaging machinery configurations and complete production line layouts tailored to your facility, processes, and future growth plans.

Manufacturing & Testing

Rigorous factory testing with your actual products ensures the vertical form fill seal machine meets all performance specifications and quality standards before shipment.

Installation & Go-Live

Professional installation, comprehensive operator training, and thorough commissioning ensure smooth production startup and optimal performance from day one.

Start your packaging transformation journey today