Comprehensive Quality Management

From design to delivery, our ISO 9001 certified quality management system ensures every packaging machine

meets the highest standards of precision, reliability, and performance.

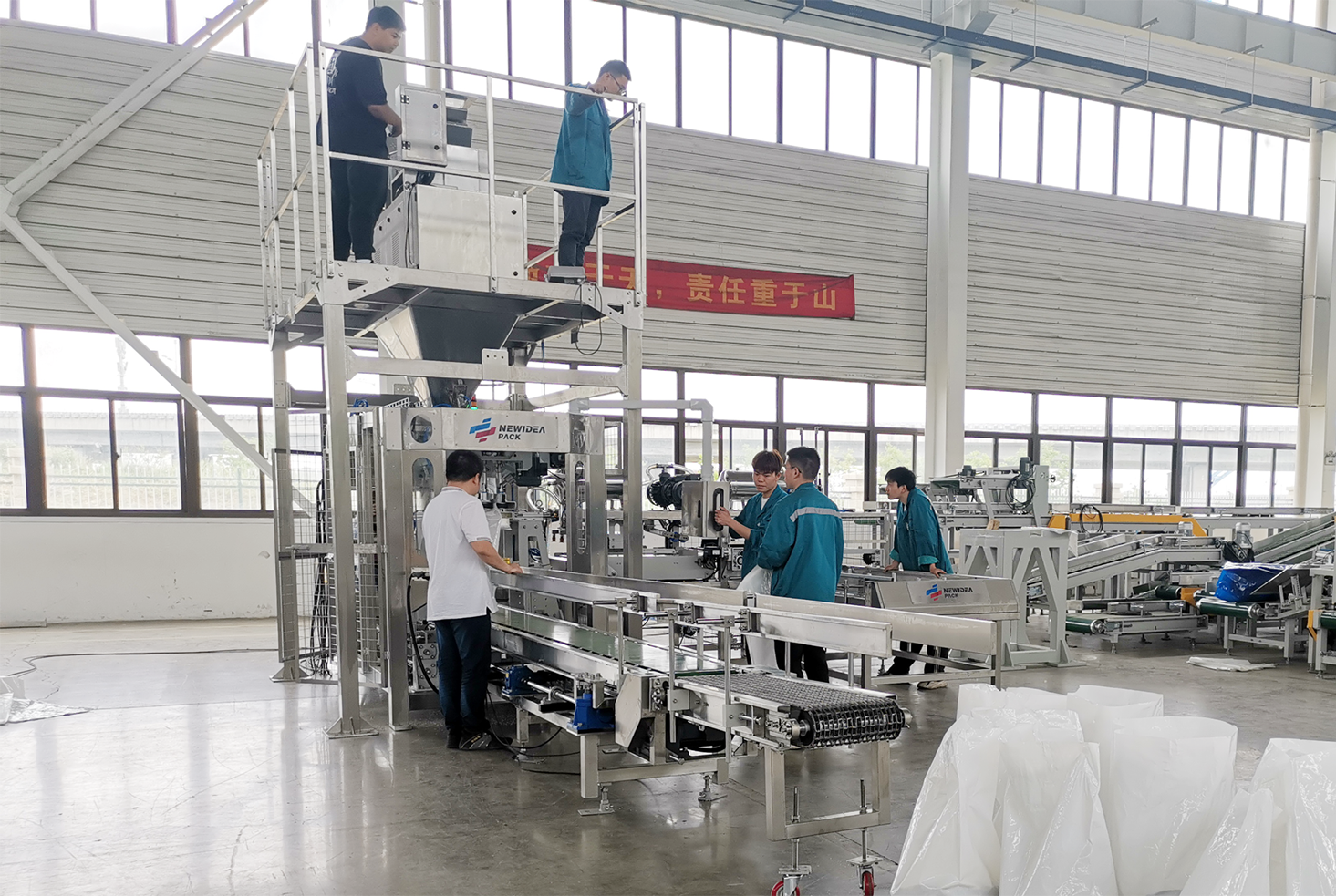

Quality Control Throughout Manufacturing

Our comprehensive quality management system covers every stage of production, ensuring consistent excellence and reliability in every machine we deliver.

Design Phase

Custom engineering with precise specifications and client requirement analysis.

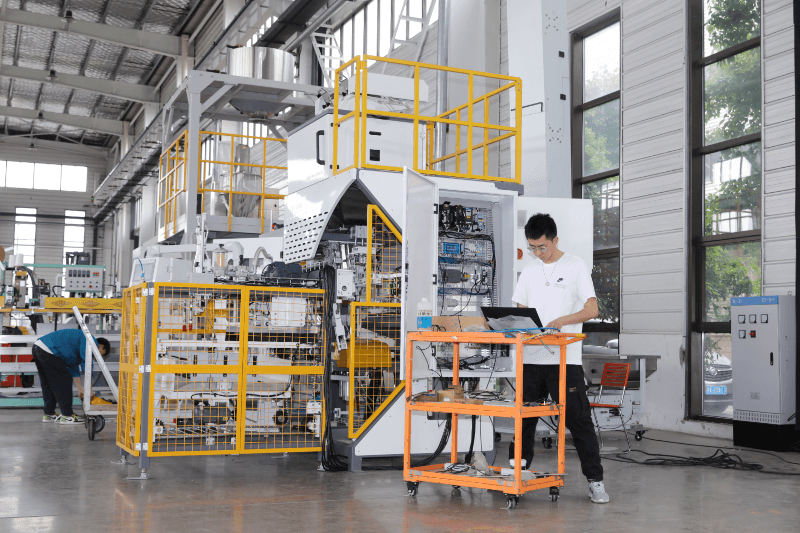

Component Testing

Rigorous testing of all electrical and mechanical components before assembly.

Production Control

ISO 9001 certified manufacturing processes with continuous quality monitoring.

Final Inspection

72-hour testing protocols and comprehensive quality verification before shipping.

Precision Design Engineering

Our design process ensures optimal machine performance tailored to your specific requirements and production environment.

Custom Design Solutions

- Feature: Structural layout optimization based on factory floor constraints and workflow requirements.

- Advantage: Perfect integration with existing production lines, minimizing disruption and maximizing efficiency.

- Benefit: Reduce installation time by 40% and achieve seamless workflow integration from day one.

- Feature: Material-specific customization for different packaging film types and product characteristics.

- Advantage: Optimized sealing parameters and handling systems for your exact packaging materials.

- Benefit: Achieve 99.8% seal integrity and reduce material waste by 15-20%.

Premium Component Selection

We exclusively use world-renowned brand components to ensure maximum reliability, longevity, and easy maintenance.

Siemens

Feature: Advanced PLC systems and servo drives for precise control and automation.

Advantage: Industry-leading reliability with 99.9% uptime and global service network.

Benefit: Minimize downtime and ensure consistent production quality with easy troubleshooting.

Schneider

Feature: High-performance electrical components including contactors and circuit breakers.

Advantage: Enhanced safety features and energy-efficient operation reducing power consumption.

Benefit: Lower operating costs and improved workplace safety with certified protection systems.

Panasonic

Feature: Precision sensors and vision systems for accurate product detection and positioning.

Advantage: Superior accuracy with ±0.1mm positioning tolerance and rapid response times.

Benefit: Achieve consistent packaging quality and reduce rejection rates by 95%.

FESTO

Feature: Premium pneumatic components and automation solutions for smooth operation.

Advantage: Exceptional durability with extended maintenance intervals and precise air control.

Benefit: Reduce maintenance costs by 30% and ensure consistent machine performance.

International Quality Certifications

Our comprehensive certifications ensure compliance with global standards and provide confidence in our manufacturing excellence.

ISO 9001:2015

Feature: Certified quality management system with documented processes and continuous improvement.

Advantage: Consistent quality standards and traceable manufacturing processes.

Benefit: Guaranteed quality consistency and reduced risk of defects or performance issues.

CE Marking

Feature: European Conformity certification ensuring safety, health, and environmental compliance.

Advantage: Direct market access across European Union without additional testing requirements.

Benefit: Seamless global deployment and compliance with international safety standards.

SGS Verification

Feature: Third-party verification of manufacturing capabilities and quality control processes.

Advantage: Independent validation of our claims and manufacturing standards.

Benefit: Enhanced confidence in equipment reliability and performance guarantees.

FDA Compliance

Feature: Food-grade materials and manufacturing processes meeting FDA requirements.

Advantage: Direct access to US market with equipment suitable for food packaging applications.

Benefit: Meet the world's strictest food safety standards and expand market opportunities.

Comprehensive Testing Protocols

Every machine undergoes rigorous testing across multiple categories to ensure optimal performance and reliability before delivery.

Structural Integrity Testing

Feature: Comprehensive structural testing including sealing block durability, machine linkage continuity, and cylinder endurance testing.

Advantage: Identifies potential mechanical weaknesses before deployment, ensuring long-term reliability.

Benefit: Achieve 99.5% mechanical uptime and extend equipment lifespan by 25% compared to industry standards.

- 48-hour continuous linkage stress testing

- Sealing block pressure endurance testing

- Pneumatic cylinder lifecycle validation

- Frame stability and vibration analysis

Electrical System Validation

Feature: Complete electrical system testing including sensor accuracy, temperature control stability, and motor overload capacity.

Advantage: Ensures precise control and prevents electrical failures that could disrupt production.

Benefit: Eliminate electrical-related downtime and maintain ±0.1°C temperature accuracy for optimal sealing.

- Sensor response accuracy verification

- Temperature controller stability testing

- Servo motor overload protection testing

- Control system integration validation

Individual Component Testing

Feature: Dedicated testing of sealing elements, pressure systems, and temperature controls for optimal performance.

Advantage: Validates each critical component independently, ensuring integrated system reliability.

Benefit: Achieve consistent seal strength and eliminate packaging defects that could damage brand reputation.

- Sealing element durability testing (10,000+ cycles)

- Pressure system calibration and validation

- Temperature uniformity across heating elements

- Film handling system precision testing

72-Hour Performance Testing

Feature: Continuous 72-hour operation testing with actual materials and films to simulate real production conditions.

Advantage: Identifies any performance issues under actual operating conditions before delivery.

Benefit: Machines are production-ready upon arrival, eliminating costly startup delays and adjustment periods.

- Continuous 24/7 operation monitoring

- Production speed and quality consistency testing

- Parameter optimization and fine-tuning

- Complete performance documentation

Protected Transportation & Delivery

Our comprehensive packaging and transportation process ensures your equipment arrives in perfect condition, ready for immediate installation.

Premium Protection

Feature: Six-layer wooden packaging with foam cushioning and moisture protection wrapping.

Advantage: Superior protection against impacts, moisture, and handling damage during transit.

Benefit: 99.8% damage-free delivery rate and immediate installation readiness upon arrival.

Secure Mounting

Feature: Specialized fixing bolts and anti-vibration mounting systems throughout transport packaging.

Advantage: Prevents mechanical stress and maintains precision calibration during shipping.

Benefit: Maintain factory calibration accuracy and reduce installation time by eliminating re-calibration needs.

Full Insurance Coverage

Feature: Comprehensive insurance coverage and GPS tracking throughout the transportation process.

Advantage: Complete protection against unforeseen circumstances and real-time shipment monitoring.

Benefit: Zero financial risk and complete visibility of delivery timeline for production planning.

Get Quality Documentation & Consultation

Request detailed quality certifications, testing reports, and personalized consultation about our quality management processes.

Quality Assurance You Can Trust

Our quality management system ensures every machine meets the highest standards of performance, reliability, and safety. Get detailed documentation and expert consultation on our quality processes.

What You'll Receive:

- Quality Certificates: ISO 9001, CE, SGS, and FDA compliance documentation

- Testing Reports: Detailed test results and performance validation data

- Component Specifications: Premium brand component details and warranties

- Quality Consultation: Expert guidance on quality requirements for your application

Quality Guarantee

Response Time: Quality documentation within 24 hours

Expert Consultation: Direct access to our quality engineers

Ongoing Support: Quality monitoring throughout equipment lifecycle