How to Master Primary Packaging Machines for Unmatched Brand Reputation Success

Primary Packaging Machines are the systems that handle the material in direct contact with your actual product. You might be wondering why this specific stage is so vital for your brand’s reputation. It ensures a sterile, airtight, and safe environment that preserves the shelf life of your goods.

How do filling machines maintain accuracy?

Filling systems use advanced sensors to measure precise volumes of liquid or powder for every container. Check this out: consistent filling prevents product giveaway and ensures you meet strict regulatory weight requirements.

Filling machines are engineered for distinct product consistencies.

For example:

- Piston fillers for thick pastes.

- Gravity fillers for thin liquids.

- Auger fillers for fine powders.

What makes sealing machines reliable?

Reliable sealing equipment uses controlled heat and pressure to create an impenetrable barrier against external contaminants. This is where it gets interesting because a single weak seal can lead to entire batch recalls.

- Induction sealers for bottles.

- Continuous band sealers for pouches.

- Vacuum sealers for perishable items.

Key Takeaway: Investing in primary packaging ensures your product reaches the end-user in the exact condition you intended.

| Machine Type | Primary Function | Ideal Industry |

| Liquid Filler | Volumetric dosing | Beverage & Pharma |

| Band Sealer | Hermetic closing | Food & Chemical |

These specific configurations help you maintain a high standard of quality control across all production runs.

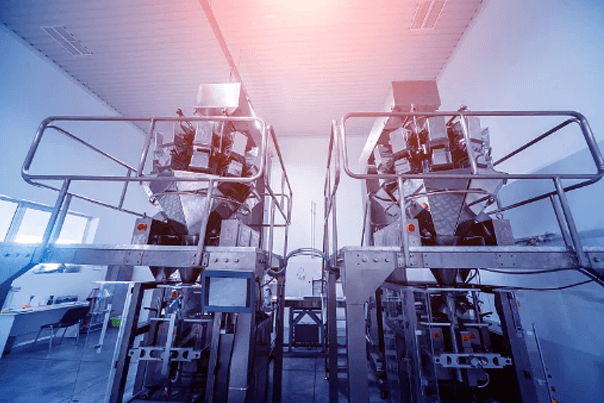

2. How Do Multi-Function VFFS Packaging Machines Save Floor Space?

Vertical Form Fill Seal (VFFS) Packaging Machines are the workhorses of the modern factory because they combine three steps into one footprint. Ready for the good part? These units take a flat roll of film, shape it into a bag, fill it with product, and seal it shut vertically.

Can VFFS handle different bag styles?

VFFS systems are incredibly versatile and can produce pillow bags, gusseted bags, or flat-bottom pouches with minimal changeover time.Furthermore,The best part is that you only need one machine to handle various SKU requirements.

- Pillow pouches for snacks.

- Chain bags for hardware.

- Gusseted bags for coffee beans.

Why is speed a factor in VFFS?

High-speed VFFS units utilize servo-driven technology to cycle hundreds of bags per minute without losing seal quality. Believe it or not, this allows small to medium businesses to compete with much larger manufacturing entities.

- Servo-motor film pulling.

- Precise jaw alignment.

- Integrated date coding.

Key Takeaway: VFFS machines provide a high ROI by maximizing output while occupying the smallest possible square footage in your facility.

| Feature | VFFS Benefit | Impact |

| Vertical Design | Small footprint | Saves warehouse space |

| Integrated Filling | One-step process | Reduces labor cost |

Choosing a VFFS system allows for rapid scaling without the need for massive infrastructure overhauls.

3. What Are the Benefits of HFFS Packaging Machines for Solid Goods?

Horizontal Form Fill Seal (HFFS) Packaging Machines are designed for products that need to be laid flat during the wrapping process. What’s the real story? These machines provide a professional, tight-fitting wrap that is ideal for bakery items, medical devices, and individual components.

Is flow wrapping better for fragile items?

Flow wrappers glide products along a horizontal plane, which prevents the tumbling or dropping often seen in vertical systems. Here’s the kicker: this gentle handling is essential for maintaining the aesthetic integrity of delicate biscuits or electronic parts.

- Rotary heat sealers.

- Adjustable bag formers.

- In-feed conveyor belts.

How does HFFS improve shelf appeal?

HFFS equipment produces sleek, clear, and perfectly centered graphics on your packaging that catch the consumer’s eye. Keep this in mind, as superior presentation often dictates the perceived value of your B2B offerings.

- Registered film tracking.

- Tight shrink-wrap options.

- End-fin folding precision.

Key Takeaway: Use HFFS machines when your product requires a premium look and gentle handling to avoid breakage.

| Feature | HFFS Advantage | Best Product Fit |

| Horizontal Path | Gentle movement | Cookies, Bars, Masks |

| Side Sealing | Clean finish | Professional retail goods |

So.The horizontal layout is the industry standard for products that must remain oriented in a specific direction.

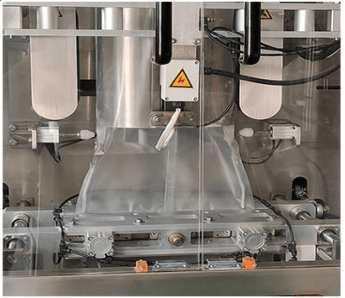

4. Why Should You Use Specialized Pouch Packaging Machines?

Premade pouch Packaging Machines are becoming the preferred choice for brands looking for a high-end, stand-up aesthetic. You might be wondering why you would buy premade bags instead of making them from rolls. The answer lies in the complex features like zippers and spouts that are easier to handle on these specialized units.

Are stand-up pouches more effective for retail?

Stand-up pouches provide a large surface area for branding and sit upright on shelves, making them highly visible to customers. Think about it: a bag that stands up by itself tells the customer that the product inside is premium.

- Doypack pouch style.

- K-seal configurations.

- Zipper-lock integration.

Can these machines handle liquids and solids?

Modern rotary pouch machines are designed with interchangeable nozzles to switch between powders, granules, or viscous liquids easily. Wait, there’s more, because these machines can even handle specialized spouted pouches for baby food or detergents.

- Vacuum suction bag opening.

- Multi-head scale integration.

- Liquid injection pumps.

Key Takeaway: Premade pouch machines offer the highest level of retail presentation and functional features like resealable zippers.

| Pouch Feature | Machine Capability | Consumer Benefit |

| Resealable Zipper | Zipper opening/closing | Product freshness |

| Bottom Gusset | Pouch stojing | Ease of storage |

So.Moving to premade pouches is a significant step toward positioning your brand in the premium market segment.

5. How Do Vacuum Packaging Machines Extend Product Life?

Vacuum Packaging Machines are the ultimate solution for preventing oxidation and spoilage in sensitive goods. But here’s the kicker:

By removing oxygen from the package, you can extend the shelf life of food products by up to five times. In addition, this oxygen-free environment prevents mold growth and preserves the product’s original flavor and texture.

Why is oxygen removal necessary?

Removing air stops the growth of aerobic bacteria and mold, which are the primary causes of food decomposition. This is where it gets interesting for B2B distributors who need to ship perishables over long distances without refrigeration.

- Chamber vacuum systems.

- External suction units.

- Modified Atmosphere Packaging (MAP).

Is vacuum sealing useful for non-food items?

In the industrial sector, vacuum sealing protects metal parts from corrosion and sensitive electronics from moisture damage. Ready for the good part? It also reduces the volume of soft goods like textiles, significantly lowering your shipping costs.

- Anti-static bags.

- Bulk volume reduction.

- Moisture-proof barriers.

Key Takeaway: Vacuum packaging is an essential investment for anyone dealing with perishable goods or items susceptible to environmental damage.

| Method | Shelf Life Extension | Typical Use |

| Standard Vacuum | 3x to 5x extension | Meat, Cheese, Nuts |

| Gas Flush (MAP) | Color preservation | Fresh Salad, Red Meat |

So.Effective vacuum sealing reduces waste and ensures your clients receive fresh, high-quality products every time.

6. What Role Do Capping Packaging Machines Play in Safety?

Capping Packaging Machines are the final line of defense in ensuring that bottled products are leak-proof and tamper-evident. What’s the real story? Without a precise capping process, your products could leak during transit, leading to costly damages and unhappy customers.

How do machines ensure consistent torque?

Automated cappers use adjustable clutches to apply the exact amount of force required to secure a lid without stripping the threads. Check this out: Therefore, this consistency is impossible to achieve through manual labor, especially over an eight-hour shift.

- Chuck capping heads.

- Spindle capper wheels.

- Snap-on capping systems.

Are tamper-evident caps necessary?

In industries like pharmaceuticals and food, tamper-evident seals are a legal requirement to ensure consumer safety. Believe it or not, a machine-applied cap provides a level of security and professional finish that builds immediate trust with the end-user.

- Shrink sleeve tunnels.

- Induction foil liners.

- Break-away ring caps.

Key Takeaway: Capping machines protect your product from leaks and provide the “first-opening” security consumers demand.

| Capper Type | Container Compatibility | Speed Level |

| Spindle Capper | Various bottle sizes | High-speed continuous |

| Rotary Capper | Dedicated bottle sizes | Ultra-high precision |

Selecting the right capping technology prevents the logistical nightmare of leaking containers in your supply chain.

7. How Do Labeling Packaging Machines Improve Brand Trust?

Labeling Packaging Machines do more than just apply stickers; they communicate your brand identity and regulatory information. You might be wondering if hand-labeling is sufficient, but crooked or bubbling labels can make a high-quality product look cheap and unreliable.

Can machines handle different bottle shapes?

Whether you have round, square, or oval containers, modern labeling systems use synchronized belts to align the label perfectly every time. Here’s the deal: precise placement ensures that all your products look uniform and professional on the retail shelf.

- Wrap-around labeling.

- Front and back application.

- Top-surface labeling.

Why is print-and-apply technology useful?

For B2B logistics, print-and-apply systems can generate unique barcodes and shipping data in real-time as the product moves down the line. The best part is that this automates your inventory tracking and reduces human error in warehouse management.

- Direct thermal printing.

- Real-time data syncing.

- High-speed application.

Key Takeaway: Automated labeling ensures a professional brand image and eliminates the errors associated with manual data entry.

| Labeler Type | Application | Surface Type |

| Wrap-around | Bottles & Cans | Cylindrical |

| Side Labeler | Boxes & Pouches | Flat or Curved |

Uniform labeling is a subtle but powerful way to signal quality and reliability to your B2B partners.

8. What Are Cartoning Packaging Machines Used For?

Cartoning Packaging Machines take flat cardboard blanks and transform them into finished boxes filled with your product. But here’s the kicker: this secondary packaging layer provides the structural strength needed for stacking and protects the primary container during shipping.

How do automatic cartoners increase efficiency?

These machines can fold, insert, and glue cartons at speeds that far exceed manual assembly lines. Think about it: if you are moving thousands of units, the labor savings alone will pay for the machine in a matter of months.

- End-load cartoners.

- Top-load systems.

- Automatic leaflet insertion.

Is carton protection necessary for B2B?

For bulk shipping, the carton acts as a shock absorber that prevents the primary bottles or bags from rupturing under pressure. Wait, there’s more, because cartons also allow for much easier palletization and organization in a distribution center.

- Tuck-in closures.

- Hot melt glue sealing.

- Reinforced corrugated options.

Key Takeaway: Cartoning machines streamline the final stage of product preparation and ensure safe bulk transport.

| Cartoner Type | Loading Style | Typical Product |

| Horizontal | Side-load | Toothpaste, Trays |

| Vertical | Top-load | Jars, Multi-packs |

A robust cartoning process is essential for any business looking to transition from local sales to national distribution.

9. Why Are Case Packing Packaging Machines Essential for Bulk?

Case packing Packaging Machines are the final step in the automation chain, placing individual units into large shipping crates. Ready for the good part? By automating this step, you remove the physical strain on workers and significantly speed up the outbound logistics process.

Can case packers handle different formats?

Modern case packers are flexible enough to handle bottles, boxes, or bags using specialized grippers or vacuum heads. This is where it gets interesting because you can program different pack patterns (e.g., 4×6 or 2×3) with a simple touch-screen adjustment.

- Pick-and-place robotics.

- Side-load case packers.

- Drop-style packers.

How does automation reduce shipping damage?

Automated systems place items into cases with consistent force and alignment, reducing the risk of crushed corners or broken seals. Here’s the deal: a perfectly packed case is much more stable on a pallet, which prevents tipping during transit.

- Precision servo-alignment.

- Buffer systems for flow control.

- Integrated case sealing.

Key Takeaway: Case packing is the key to scaling your operations and ensuring your bulk shipments arrive safely and organized.

| Packer Type | Technology | Application |

| Robotic | 4-Axis or 6-Axis | Complex orientations |

| Mechanical | Grid/Drop | High-volume simple goods |

Automating the heavy lifting of case packing allows your team to focus on quality control rather than manual labor.

10. How to Choose the Right Packaging Machines for Your Business?

Choosing the right Packaging Machines requires a deep understanding of your product characteristics, production volume, and budget. What’s the real story? Buying a machine that is too small will limit your growth, while one that is too large may never see a return on investment.

What specifications should you prioritize?

You must look at your required output speed, the range of sizes the machine can handle, and the ease of cleaning. Keep this in mind: a machine that is easy to maintain will have much less downtime and a longer overall lifespan.

- Production speed (PPM).

- Material compatibility (PE, PET, Paper).

- Changeover time requirements.

How do you calculate the ROI?

To find the true value, compare the cost of the machine against the reduction in labor hours, material waste, and increased output capacity. Believe it or not, most businesses find that high-quality automation pays for itself within 12 to 18 months of operation.

- Labor cost reduction.

- Material savings.

- Increased market share.

Key Takeaway: Consult with a professional expert to ensure the machine specifications align with your long-term business goals.

| Consideration | Priority Level | Reason |

| Speed (PPM) | High | Determines daily revenue |

| Footprint | Medium | Must fit in existing space |

Making an informed decision today ensures your production line remains competitive and profitable for years to come.

Final Thoughts

Finding the perfect packaging solution is the difference between surviving and thriving in a competitive market. We have explored everything from primary filling to final case packing, highlighting how each step adds value to your production chain. But here’s the kicker: technology is only half the battle; you need a partner who understands your specific industry needs. At NewIdeaPack, we specialize in high-performance equipment designed to scale with your ambitions. If you are ready to eliminate bottlenecks and protect your margins, contact us today for a professional consultation. Our vision is to empower global manufacturers with the precision tools they need for a sustainable and efficient future.

FAQ

Q1: What is the best way to determine which machine I need first?

Start by identifying your biggest bottleneck. If manual filling is slowing you down, a filler is your priority; if you have too much breakage, look at sealing or cartoning.

Q2: How do I know if a machine can handle my specific product material?

Consult the manufacturer’s compatibility list. Most modern machines are designed for a wide range of films and containers, but testing a sample is always recommended.

Q3: Can I integrate new machines into my existing manual line?

Absolutely. Many systems are designed as modular units that can be added one by one to slowly automate your production as your budget allows.

Q4: What’s the best maintenance schedule for high-speed equipment?

Daily cleaning and weekly lubrication are standard. Most professional-grade machines also require a deeper inspection every six months to replace wear-and-tear parts.

Q5: How do I know if the ROI justifies the initial cost?

Calculate your current cost per unit using manual labor and compare it to the projected cost using automation. Most businesses see a full return within two years.