PLC Control Systems: How to Maximize Machine Precision

Maximizing machine precision requires integrating high-performance PLC control systems that synchronize hardware and software with millisecond accuracy. You are likely struggling with inconsistent bag weights, messy seals, or unpredictable downtime that eats into your margins. It is frustrating to watch product waste pile up because your current equipment cannot maintain tight tolerances. At newideapack, we provide the solution with a specialized PLC packaging machine engineered to deliver surgical accuracy for your production line.

Why is a PLC packaging machine essential for precision?

A PLC serves as the central “brain” of your operation, executing complex logic sequences to ensure every mechanical action is perfectly timed. By utilizing a PLC packaging machine, you replace variable manual settings with rigid digital parameters that do not drift over time.

Think about it:

- Microsecond response times for sensor inputs.

- Perfect synchronization between feeders and sealers.

- Automatic error correction without operator intervention.

The best part?

Does digital logic improve timing?

Digital logic ensures that your machine components move in a choreographed dance that never misses a beat. Unlike mechanical cams that wear down, a digital program maintains the exact same timing for millions of cycles.

How does central control reduce errors?

Centralized control allows every sensor on your line to talk to the main processor instantly. This prevents the “lag” that often causes overfilling or misalignment in older, less integrated systems.

Key Takeaway: A centralized PLC ensures that every mechanical stroke is mathematically precise, leading to higher product quality and less rework.

| Control Element | Precision Impact | Operational Result |

|---|---|---|

| Digital Logic | Eliminates mechanical drift | Consistent cycle times |

| Signal Processing | Reduces input lag | Instant error detection |

| Centralized Sync | Coordinates all axes | Zero misalignment |

The integration of digital logic transforms your production floor from a series of independent parts into a single, high-precision unit.

How does logic control reduce mechanical errors?

Logic control eliminates the variability found in manual gears by using digital code to govern every physical movement of the PLC packaging machine. This digital-first approach ensures that mechanical wear and tear do not translate into packaging defects or inconsistent fills.

Here is the deal:

- Programmable limits prevent mechanical over-travel.

- Digital filters ignore electrical noise that causes glitches.

- Logical interlocks prevent the machine from starting if parts are misaligned.

But wait, there’s more.

Can software replace mechanical adjustments?

Software allows you to fine-tune your machine’s behavior through a screen rather than a wrench. This means your “mechanical” settings are locked into the code and cannot be accidentally bumped or moved.

Why is real-time feedback critical?

Real-time feedback loops allow the system to adjust its own parameters based on actual performance data. If a motor begins to slow down, the logic control can increase power instantly to maintain the target speed.

Key Takeaway: Digital logic acts as a safety net that catches and corrects mechanical inconsistencies before they turn into expensive product waste.

| Error Type | Logic Solution | Final Benefit |

|---|---|---|

| Mechanical Drift | Digital parameter locking | Permanent calibration |

| Signal Noise | Software filtering | Stable operation |

| Human Error | Logical interlocks | Safe and precise runs |

Transitioning from mechanical cams to digital logic is the fastest way to stabilize your packaging tolerances.

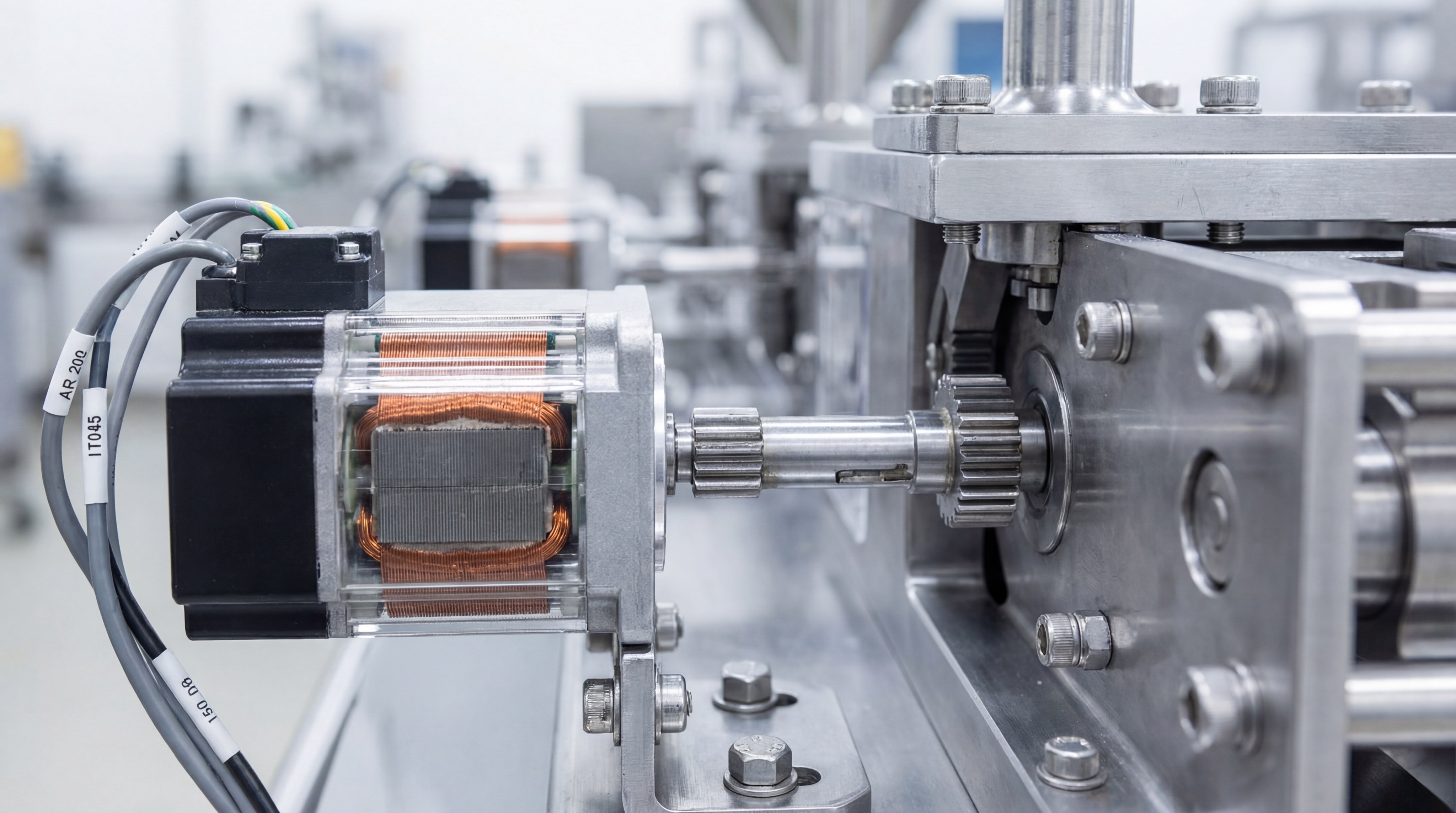

What role do servo motors play in precision control?

Servo motors provide the high-torque, high-resolution movement needed for the PLC packaging machine to position components within fractions of a millimeter. These motors report their exact position back to the PLC thousands of times per second to ensure total accuracy.

You might be wondering:

- Exact positioning for film registration.

- Controlled acceleration to prevent product splashing.

- Variable speed profiles for different bag lengths.

Look at this:

How does encoder feedback help?

Encoders act as the “eyes” of the motor, telling the PLC exactly where the shaft is at any given moment. This allows for closed-loop control where the machine constantly verifies its own movements.

Why is torque control important?

Torque control allows the machine to apply the perfect amount of force during the sealing process. This prevents the motor from crushing delicate materials while ensuring a hermetic seal is formed every time.

Key Takeaway: Servo technology provides the physical muscle that executes the PLC’s precise commands with unmatched repeatability.

| Motor Feature | Precision Function | Impact |

|---|---|---|

| Encoder Feedback | Position verification | +/- 0.01mm accuracy |

| Dynamic Torque | Force regulation | Consistent seal pressure |

| Speed Profiles | Smooth motion | No product spillage |

The marriage of high-speed servos and PLC logic creates a system capable of handling the most demanding packaging requirements.

Can advanced sensors improve filling accuracy?

Advanced sensors provide the raw data that allows a PLC packaging machine to adjust filling weights and volumes in real-time. By monitoring the flow of product constantly, the system can shut off the filling nozzle at the exact millisecond the target is reached.

Believe it or not:

- Load cells detect milligram changes in weight.

- Optical sensors confirm correct product placement.

- Ultrasonic sensors check for bag opening success.

The best part?

Do checkweighers improve the process?

Integrated checkweighers send data back to the PLC to automatically adjust the filler for the next cycle. If a bag is slightly light, the PLC tells the auger to spin a fraction more on the next turn.

Can sensors detect film defects?

Registration sensors look for specific marks on your film to ensure the cutting blade hits the exact same spot every time. This prevents your branding from being cut off or misaligned on the shelf.

Key Takeaway: High-resolution sensors turn the PLC into a self-aware system that can “see” and “feel” every step of the packaging process.

| Sensor Type | Specific Function | Resulting Precision |

|---|---|---|

| Load Cell | Weight monitoring | Minimized product giveaway |

| Photoeye | Film tracking | Perfect graphics alignment |

| Ultrasonic | Material detection | Zero-waste empty cycles |

Using data-driven sensing allows your facility to maintain high standards even with variable raw materials.

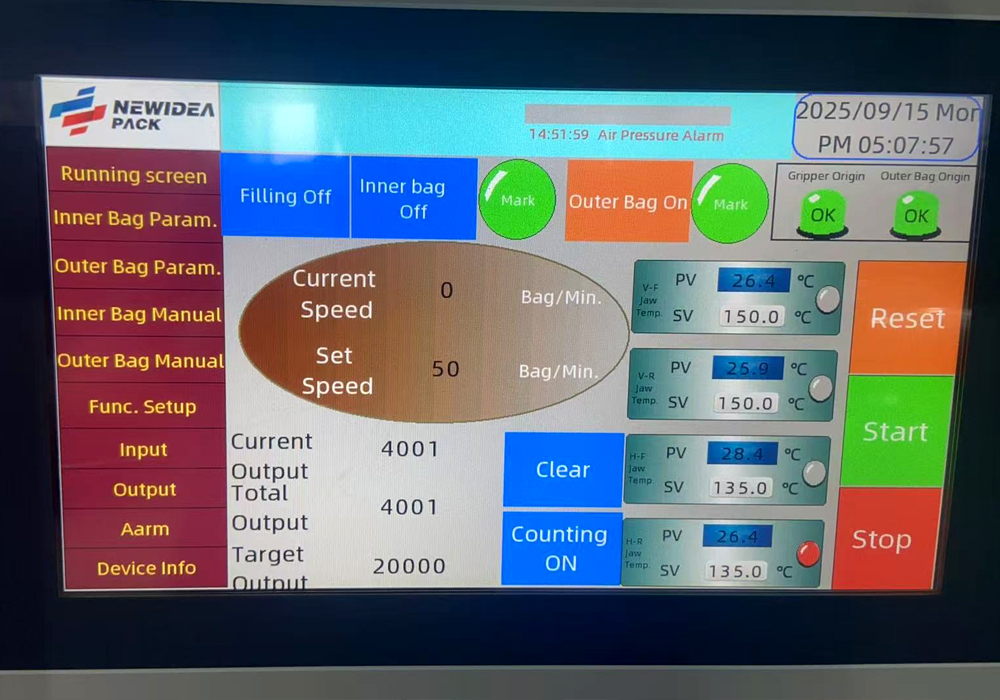

Why is the HMI interface vital for operator precision?

A modern Human-Machine Interface (HMI) allows your staff to interact with the PLC packaging machine without needing to understand complex computer code. By presenting data in a visual format, the HMI helps operators make precise adjustments that keep the line running smoothly.

At newideapack, we focus on:

- Visual alerts for immediate troubleshooting.

- Real-time production metrics on one screen.

- Graphical representations of machine health.

Think about this:

Is a visual dashboard better?

A visual dashboard uses icons and colors to communicate machine status, which reduces the chance of an operator misinterpreting technical data. This clarity is essential during high-pressure production runs.

Does multi-level access improve safety?

Password-protected levels ensure that only trained technicians can change critical precision settings. This prevents unauthorized personnel from accidentally altering the machine’s calibration.

Key Takeaway: An intuitive HMI empowers your team to maintain machine precision through clear communication and controlled access to settings.

| HMI Feature | Operator Benefit | Accuracy Impact |

|---|---|---|

| Visual Graphs | Quick data analysis | Faster response to drift |

| Error Mapping | Localizes issues | Reduced downtime |

| Multi-language | Clearer instructions | Fewer operational mistakes |

Clearer interfaces lead to smarter operators and a much more stable production environment.

How does high-speed motion affect packaging stability?

High-speed motion is managed by the PLC packaging machine to ensure that increased velocity does not lead to mechanical vibration or sealing failures. The PLC uses advanced algorithms to smooth out the start-and-stop movements that would otherwise cause “mechanical noise.”

Here is the secret:

- S-curve acceleration profiles for gentle movement.

- Synchronized multi-axis control to prevent collisions.

- High-frequency temperature monitoring for fast seals.

Now, listen closely:

Can the PLC handle high vibration?

Advanced motion control filters out the vibrations that occur at high speeds, keeping the bag-forming process stable. This ensures that even at 100 bags per minute, every bag looks identical.

How does the system stay cool?

When running fast, sealing jaws generate significant heat that must be dissipated or precisely controlled. The PLC monitors these thermal levels every millisecond to prevent burnt films.

Key Takeaway: Achieving high-speed precision is only possible when a PLC can coordinate motion and temperature with absolute synchronicity.

| Speed Factor | PLC Solution | Quality Result |

|---|---|---|

| Acceleration | S-Curve Logic | No product splashing |

| Multi-axis Sync | Electronic Camming | Perfectly timed cuts |

| Heat Management | PID Control | Strong, clean seals |

Stability at high speeds is the hallmark of a truly professional packaging system.

Does recipe management ensure production consistency?

Recipe management allows the PLC packaging machine to store thousands of unique settings for different products, ensuring that every batch is produced with the exact same parameters. Instead of manual setup, your operator simply selects a name from the list to apply the correct timing and temperature.

This means:

- Zero-calibration time between products.

- Perfect consistency for repeat orders.

- Instant scaling for different bag sizes.

But that is not all.

Why are saved parameters safer?

Saved parameters remove the “human element” from the setup process, ensuring that the machine runs exactly as it did during its last successful run. This eliminates the “trial and error” phase of production.

Can I export recipe data?

Modern PLCs allow you to backup and export your recipe files to other machines in your facility. This ensures that your entire fleet operates with the same level of precision.

Key Takeaway: Digital recipes turn complex setup tasks into simple, one-touch operations that guarantee product uniformity every time.

| Recipe Component | Saved Data | Result |

|---|---|---|

| Filling Volume | Auger/Pump cycles | Exact weight every time |

| Sealing Temps | PID setpoints | No weak or burnt seals |

| Bag Length | Pull-belt pulses | Consistent dimensions |

Reliable recipes are your best tool for maintaining brand standards across multiple shifts and locations.

What diagnostic tools help maintain machine uptime?

Diagnostic tools built into the PLC packaging machine identify potential failures before they stop your line, allowing for proactive maintenance that preserves precision. Instead of guessing why a machine stopped, the PLC provides a detailed error code and a location map.

Consider this:

- Real-time I/O monitoring for every sensor.

- Historical error logging for trend analysis.

- Predictive maintenance alerts for motor wear.

It gets better:

How do visual error maps work?

Visual maps highlight the exact component that is failing on a 3D model of the machine. This allows your maintenance team to bypass hours of searching and go straight to the problem.

Can remote support save time?

Remote access allows an engineer to log into your PLC from across the world to diagnose software glitches. This provides instant expert help without the cost of a site visit.

Key Takeaway: Integrated diagnostics reduce the “Mean Time To Repair” (MTTR), keeping your machine making money instead of sitting idle.

| Tool | Function | Maintenance Benefit |

|---|---|---|

| Error History | Tracks repeating issues | Root cause identification |

| Sensor Status | Monitors individual signals | Fast electrical checks |

| Health Monitor | Predicts component life | Scheduled part replacement |

Diagnostic data is the key to evolving from reactive repairs to a sophisticated predictive maintenance strategy.

How does smart factory integration enhance data precision?

Smart factory integration connects your PLC packaging machine to your central management software to provide a macro-view of your production efficiency. By sharing data across your network, the PLC helps you identify bottlenecks and optimize the performance of your entire facility.

Look at the possibilities:

- Automatic inventory tracking for films and labels.

- Energy consumption monitoring for cost control.

- Real-time OEE (Overall Equipment Effectiveness) reporting.

Here is the deal:

What is OEE tracking?

OEE tracking measures how well your machine is performing compared to its theoretical maximum. The PLC provides the raw data on speed, quality, and availability to calculate this critical metric.

How does IoT connectivity help?

IoT connectivity allows your machines to communicate with each other to synchronize line speeds. If the cartoner slows down, the packaging machine automatically adjusts its output to prevent a pile-up.

Key Takeaway: Connecting your PLC to a smart network transforms individual machines into a collaborative system that optimizes itself for maximum output.

| Integration Point | Shared Data | Business Impact |

|---|---|---|

| ERP System | Production counts | Real-time stock updates |

| SCADA | Machine status | Centralized floor control |

| Cloud Analytics | Performance trends | Long-term strategy data |

Digital integration ensures that your packaging precision is backed by powerful, actionable data.

Is regular maintenance the key to sustained accuracy?

Regular maintenance of your PLC packaging machine ensures that the physical components remain in top condition to execute the digital commands perfectly. While the PLC is highly reliable, keeping sensors clean and motors lubricated is essential for long-term precision.

You should consider:

- Daily sensor cleaning to prevent false signals.

- Weekly inspection of heating elements and wires.

- Monthly software backups to protect your data.

Think about it:

Should I clean sensors daily?

Dust and debris can block the lenses of your optical sensors, leading to “ghost” errors or missed registration marks. A simple wipe-down every morning prevents hours of troubleshooting later.

How often should I backup data?

You should backup your PLC and HMI data every time you create a new recipe or update the software. This ensures you can restore the machine to a working state in minutes if a hardware failure occurs.

Key Takeaway: A consistent maintenance schedule protects your investment and ensures your precision stays at factory-fresh levels for years.

| Schedule | Task | Precision Benefit |

|---|---|---|

| Daily | Clean sensor lenses | Reliable signal input |

| Weekly | Check seal jaw alignment | Uniform bond strength |

| Monthly | Backup system recipes | Zero data loss risk |

This data confirms that a small investment in daily care prevents major losses in long-term accuracy.

Frequently Asked Questions

Can I upgrade my current machine to a PLC control system?

Yes, retrofitting is a viable option for most mechanical systems. Replacing old cams with a PLC and servo motors will significantly increase your accuracy and speed.

How do I know if my PLC battery needs replacing?

You will see a “Low Battery” alert on your HMI screen weeks before it fails. It is vital to replace it while the power is on to avoid losing volatile memory settings.

What is the best way to prevent electrical noise in my PLC?

Ensuring your machine is properly grounded and using shielded cables for sensitive signals is the most effective method. This prevents glitches caused by nearby high-voltage equipment.

Can I control multiple packaging machines from one PLC?

Yes, modern high-capacity PLCs can manage multiple lanes or machines simultaneously. This centralizes your control logic and simplifies the integration of your entire production line.

How do I restore my machine if the PLC program is lost?

You can reload the program from a backup file stored on a USB drive or your company server. This is why regular data backups are a critical part of your maintenance routine.

Conclusion

Maximizing machine precision is an achievable goal when you leverage the power of advanced PLC control systems. By focusing on digital logic, servo integration, and smart diagnostics, you can eliminate the waste and inconsistency that hold your business back. From specialty coffee to bulk powders, the right technology ensures your brand is represented by perfect packaging every time.

If you are ready to transform your production floor with a high-accuracy solution

please contact us today to discuss your specific needs. At newideapack, we are dedicated to engineering the precision that drives your long-term success in the packaging industry.