How to Ensure Ultimate Freshness Using Drip Coffee Bag Packaging

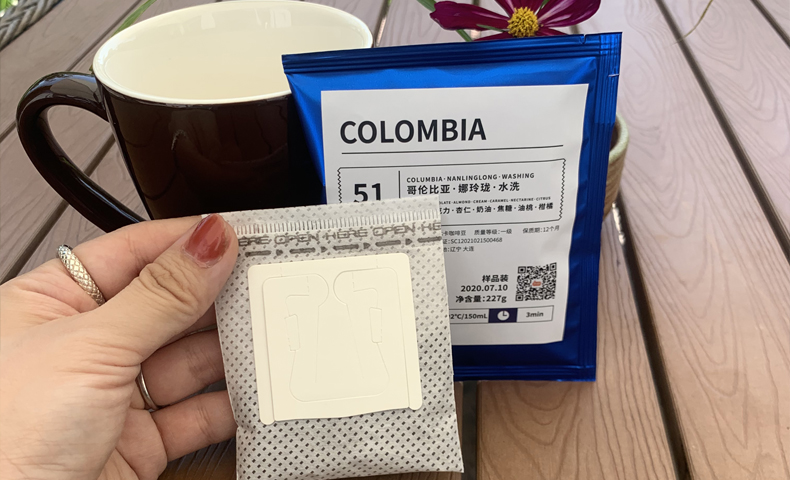

Drip coffee bags dominate the portable coffee market because they deliver the perfect balance of specialty-grade quality and unparalleled convenience for on-the-go consumers. Imagine you are a specialty coffee roaster who has spent months sourcing the finest beans, only to find that your customers are choosing low-quality instant coffee because they lack the equipment to brew your beans at the office or while traveling. It is frustrating to see your premium product lose out simply because of a “convenience gap.” This is where drip coffee bag packaging solutions revolutionize your business by transforming high-end beans into a portable, single-serve format that requires nothing more than hot water and a cup.

Why are drip coffee bag packaging solutions leading the market?

These solutions lead the market by enabling roasters to provide a “pour-over” experience without the need for bulky scales, grinders, or gooseneck kettles. As the global pace of life accelerates, you will notice that consumers are no longer willing to sacrifice flavor for speed.

Does consumer lifestyle drive this demand?

Yes, the shift toward mobile and outdoor lifestyles has made the lightweight, compact nature of drip bags the preferred choice for modern professionals. Whether it is for a quick morning fix in a hotel room or a caffeine boost during a hiking trip, your customers appreciate the “brew-anywhere” capability.

- Portability: Fits easily in pockets, laptop bags, or carry-on luggage.

- No Cleanup: The filter bag is discarded immediately after use, leaving no mess.

- Consistency: Each bag is pre-measured for a perfect water-to-coffee ratio.

But here is the interesting part.

Why is the shift from instant coffee happening now?

The rise of the “Third Wave” coffee movement means you are dealing with a more educated consumer base that understands the bitterness of instant alternatives. Drip bags allow for the use of fresh ground coffee, which retains the volatile oils and aromatic compounds lost in the freeze-drying process.

Key Takeaway: By adopting these packaging formats, you bridge the gap between high-quality specialty coffee and the convenience-driven demands of the modern workforce.

| Feature | Instant Coffee | Drip Coffee Bags |

| Flavor Profile | Flat/Bitterness | Complex/Aromatic |

| Preparation Time | 30 Seconds | 2 Minutes |

| Equipment Needed | Spoon | Cup & Hot Water |

This comparison highlights why premium brands are pivoting toward drip formats to protect their flavor integrity while scaling sales.

Do drip coffee bag packaging solutions ensure bean freshness?

Drip coffee bag packaging solutions ensure maximum freshness by utilizing advanced modified atmosphere packaging (MAP) and high-barrier materials that shield the coffee from oxygen. You know that oxygen is the ultimate enemy of ground coffee, causing it to go stale within minutes of exposure.

Can nitrogen flushing extend shelf life?

Absolutely, nitrogen flushing replaces the oxygen inside the outer envelope with an inert gas to stop oxidation in its tracks. By maintaining oxygen levels below 1%, you can extend the shelf life of your product from weeks to over a year without losing the delicate floral or fruity notes of your beans.

- Residual Oxygen Control: Keeps levels at the industry standard of <1%.

- Aroma Preservation: Seals in the volatile gases released by fresh grounds.

- Color Stability: Prevents the browning and degradation of the coffee particles.

And that is just the beginning.

How do high-barrier films provide protection?

The outer envelope is your second line of defense, acting as a physical shield against light, moisture, and external odors. You should look for multi-layer foils or specialized PET/AL/PE structures that provide a total barrier to ensure the coffee tastes as fresh as the day it was roasted.

Key Takeaway: Investing in high-barrier packaging ensures that your brand reputation is protected by every cup delivering a fresh, cafe-quality experience.

| Protection Layer | Purpose | Benefit |

| Aluminum Foil | Light & Oxygen Barrier | Prevents oxidation |

| PE Layer | Heat Sealing | Ensures air-tightness |

| Nitrogen Fill | Atmosphere Control | Stops flavor degradation |

These layers work in harmony to transform a simple bag into a high-tech preservation chamber for your premium grinds.

Why is ultrasonic technology vital for drip coffee bag packaging?

Ultrasonic technology is vital because it creates a strong, clean seal on the non-woven filter fabric without using heat that could alter the coffee’s flavor profile. If you use traditional heat sealing, you risk melting the plastic fibers into the coffee or creating a bulky seal that reduces the space for water flow.

Is ultrasonic sealing more efficient than heat?

Yes, ultrasonic sealing is significantly faster and more reliable because it bonds the fabric at a molecular level using high-frequency vibrations. This allows you to achieve a much narrower seal margin, which effectively increases the “brewing room” inside the bag for better extraction.

- Cool Sealing: No heat is transferred to the coffee grounds during the process.

- Narrow Seams: Increases the usable surface area of the filter fabric.

- Strength: Prevents bag breakage when hot water is poured vigorously.

You might be wondering about the cost.

Can ultrasonic tech reduce material waste?

By using narrower seals, you actually consume less filter fabric per bag, which leads to significant material savings over high-volume production runs. Furthermore, because the seal is instantaneous, you avoid the “warm-up” time and energy waste associated with traditional thermal sealing bars.

Key Takeaway: Transitioning to ultrasonic sealing improves both the aesthetic quality of your product and the overall extraction efficiency for the end-user.

| Sealing Method | Heat Sealing | Ultrasonic Sealing |

| Seal Width | 5mm – 8mm | 2mm – 3mm |

| Flavor Impact | Potential heat damage | Zero heat transfer |

| Filter Space | Restricted | Optimized |

The move to ultrasonic is not just a technical upgrade; it is a commitment to the sensory purity of your coffee.

Can drip coffee bag packaging solutions improve your ROI?

Drip coffee bag packaging solutions improve your ROI by drastically reducing labor costs and increasing the throughput of your production facility. When you move from manual filling to a fully automated system, you eliminate the inconsistencies and slow speeds that bottleneck your growth.

How does automation lower production costs?

Automation allows a single operator to oversee a machine that produces up to 50 bags per minute, a task that would require a large team of manual laborers. You will find that the precision of automated weighing systems also prevents “overfill” waste, ensuring every gram of expensive coffee is accounted for.

- Labor Reduction: Replaces 5-10 manual packing stations with one machine.

- Weight Accuracy: ±0.1g precision reduces product giveaway.

- High Speed: Consistent output allows for better inventory planning.

Think about the scaling potential.

What is the best way to scale your coffee brand?

The best way to scale is to adopt a system that can grow with your demand, moving from small-batch artisanal production to mass-market distribution. With a reliable packaging line, you can confidently take on large wholesale contracts for hotels, airlines, and supermarket chains.

Key Takeaway: High-speed automation turns your packaging department from a cost center into a profit-generating engine by lowering the cost-per-unit.

| Production Metric | Manual Packing | Automated Packing |

| Output (Bags/Min) | 5 – 8 | 40 – 60 |

| Weight Variance | High | Minimal |

| Operator Count | 4 – 6 | 1 |

By optimizing these metrics, you free up capital to reinvest in sourcing better beans or expanding your marketing efforts.

Drip coffee bag Conclusion

The dominance of drip coffee bags in the global market is a direct result of their ability to meet the modern consumer’s demand for high-quality, portable, and easy-to-use coffee. By implementing the right technology—from nitrogen flushing to ultrasonic sealing—you can ensure your brand remains at the forefront of this industry shift. We have explored how these systems solve the problems of freshness, production efficiency, and market reach. If you are ready to upgrade your production line and capture a larger share of the specialty coffee market, contact us today to find the perfect machinery for your needs. At NewIdeaPack, we believe that every roaster deserves the tools to bring world-class coffee to every corner of the globe.

FAQ

Can I use different types of coffee grinds in a drip bag machine?

Yes, most modern machines are designed to handle various grind sizes, though a medium-fine grind is generally recommended for optimal extraction. The vibration and dosing systems can be adjusted to maintain accuracy regardless of the coffee’s density.

What’s the best way to ensure the outer bag is perfectly airtight?

The best way is to use a high-quality composite film combined with precise heat-sealing temperatures. You should also regularly perform “leak tests” by submerging sealed bags in water to check for air bubbles.

How do I know if my production volume justifies an automatic machine?

A good rule of thumb is that if your manual team is struggling to keep up with daily orders or if your labor costs are eating more than 15% of your margin, it is time to automate. Automation usually pays for itself within 12 to 18 months of consistent use.

Can I customize the shape and size of the outer envelope?

Yes, you can certainly customize the dimensions to fit specific branding requirements or retail display boxes. Most machines offer adjustable mold sets that allow you to switch between different pouch sizes with minimal downtime.

What’s the best material for eco-friendly drip coffee bags?

The best choice is currently PLA (polylactic acid) filter fabric combined with a compostable outer film. This ensures that the entire package can be disposed of in industrial composting facilities, appealing to the growing eco-conscious market.