How To Boost Your ROI By Optimizing Packaging Machine BPM Today

Machine speed directly dictates your ROI by lowering cost-per-bag and increasing total market capacity. Many coffee roasters struggle with manual packaging bottlenecks that prevent them from scaling to larger retail contracts. These slow production speeds drive up labor costs and eat into your profit margins, making it impossible to stay competitive. The solution lies in optimizing your packaging machine BPM to align with your growth targets.

1. Why does packaging machine BPM matter for drip coffee ROI?

Packaging machine BPM determines the payback period of your industrial equipment by controlling how many units you sell per hour of operation. Higher speeds allow you to amortize the initial machine cost over millions of bags rather than thousands. This shift significantly accelerates your path to profitability.

Defining the correlation between speed and profit

How does speed translate to dollars in your pocket? When you increase your output rate, your revenue potential expands without a linear increase in overhead.

Here is why it matters:

- Faster output reduces the “cost per unit” for electricity and facility rent.

- High-volume production allows you to secure better pricing on raw materials like filter rolls and foil.

Low speeds often hide inefficiency that drains your bank account over time. If your machine is slow, you are likely paying for excessive operator hours for the same output.

But that’s not all:

- Slow machines can lead to missed shipping deadlines and lost wholesale accounts.

- Older, low-BPM units often have higher scrap rates during start-up and shut-down cycles.

| Speed Level | Revenue Potential | Fixed Cost Dilution | ROI Speed |

|---|---|---|---|

| Low (15-20 BPM) | Limited | Minimal | Slow (36+ Months) |

| High (50-70 BPM) | Substantial | Significant | Fast (10-14 Months) |

Analysis: Increasing BPM from a manual pace to 60+ BPM creates an exponential curve in net profit by slashing the time required to break even on capital expenditures.

Key Takeaway: High BPM is the primary driver of profitability because it reduces the labor and time required to fulfill high-volume orders.

2. How does packaging machine BPM influence production volume?

Higher production volume is achieved when you optimize your packaging machine BPM to handle continuous high-capacity output. Moving from 30 to 60 BPM isn’t just a 100% increase in speed; it’s a total transformation of your market capability. You can suddenly serve dozens of new retail locations with the same footprint.

Scaling from boutique to industrial levels

Can you handle a sudden order for 50,000 drip bags? With a high-speed machine, this becomes a two-day task rather than a two-week struggle.

It boils down to this:

- High BPM allows for 24/7 operation cycles without equipment fatigue.

- Industrial scaling requires consistent output to keep grocery store shelves stocked.

Meeting seasonal demand surges

Coffee demand fluctuates, especially during holiday gift seasons or summer cold brew peaks. Having a machine that can “ramp up” prevents you from turning away lucrative business.

Here is the kicker:

- You can build inventory faster during slow months to prepare for peaks.

- High BPM reduces the need for emergency seasonal hires who require expensive training.

| Shift Duration | 30 BPM Output | 60 BPM Output | Volume Difference |

|---|---|---|---|

| 8 Hours | 14,400 bags | 28,800 bags | +14,400 bags |

| 24 Hours | 43,200 bags | 86,400 bags | +43,200 bags |

Analysis: Doubling the BPM effectively doubles your revenue capacity per square foot of factory space.

Key Takeaway: Maximum throughput ensures you never hit a “glass ceiling” when large distributors request high-volume fulfillment.

3. Can low packaging machine BPM bottleneck your coffee business?

Low packaging machine BPM acts as a choke point that prevents your high-quality beans from reaching the consumer quickly. Even if you roast the best coffee in the world, a slow packing line will stall your growth. You end up with a warehouse full of bulk coffee that is losing freshness while waiting for the bagger.

Identifying the speed trap in small roasteries

Are you working harder but making less? If your roasting capacity exceeds your packaging speed, you are stuck in a classic production bottleneck.

Think about it:

- Manual weighing and filling lead to inconsistent bag weights and customer complaints.

- A slow line forces your most skilled roasters to spend time on packing labor.

The ripple effect on the supply chain

When packaging is slow, your entire logistics chain suffers from delays. This leads to shorter shelf life for the end consumer and potential returns from retailers.

But that’s not all:

- Slow packing creates a backlog that disrupts your roasting schedule.

- Inventory management becomes a nightmare when production can’t keep pace with sales.

| Bottleneck Indicator | Manual/Low BPM Line | High-Speed Automated Line |

|---|---|---|

| Freshness Window | Often compromised | Optimally preserved |

| Order Lead Time | 7-14 Days | 1-3 Days |

| QC Consistency | Variable | Highly Stable |

Analysis: Low BPM doesn’t just slow you down; it introduces human error and quality risks that can damage your brand reputation.

Key Takeaway: Eliminating the packaging bottleneck is the most effective way to synchronize your roasting capacity with market demand.

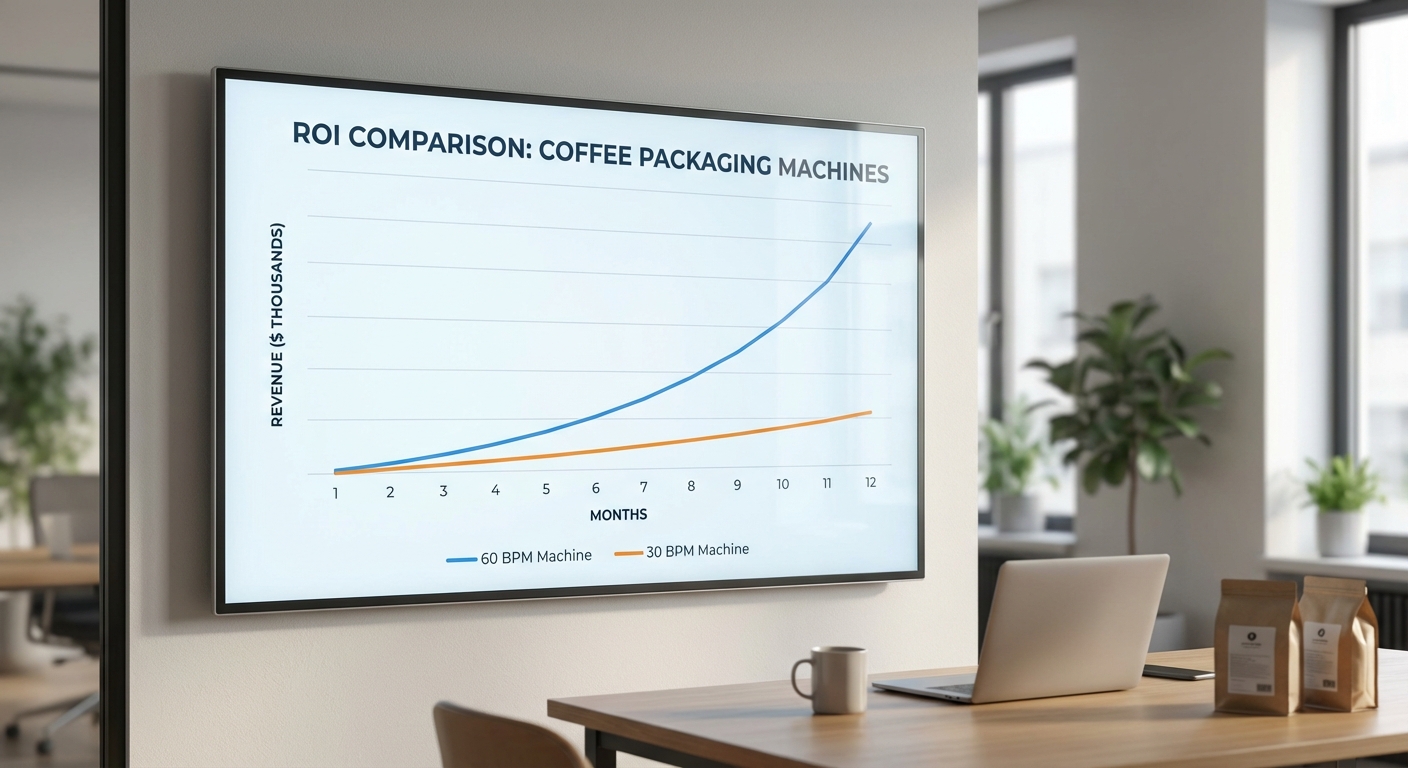

4. Is 30 vs 60 packaging machine BPM better for SME growth?

Investing in a 60 packaging machine BPM unit typically provides a 40% better ROI over three years compared to entry-level 30 BPM models. While 30 BPM is great for testing the market, 60 BPM is the industry standard for sustainable growth. It provides the headroom you need to sign larger contracts with confidence.

Comparing entry-level and mid-tier performance

Which speed fits your current stage? SMEs often fear over-investing, but under-investing in speed can be more expensive in the long run.

Here is why it matters:

- 60 BPM machines usually feature more robust components meant for long-term use.

- The cost difference between 30 and 60 BPM is often recovered in just 6 months of full operation.

Determining your break-even point

How long until the machine pays for itself? High-speed machines allow you to reach the “break-even” point much faster through sheer volume.

But that’s not all:

- A 60 BPM machine requires roughly the same floor space as a 30 BPM machine.

- You get double the productivity without doubling your rent or utility costs.

| Metric | 30 BPM (SME Entry) | 60 BPM (Growth Tier) |

|---|---|---|

| Operator Cost/Bag | $0.08 | $0.04 |

| Annual Capacity | 4.3M Bags | 8.6M Bags |

| ROI Timeline | ~20 Months | ~12 Months |

Analysis: The jump to 60 BPM is the “sweet spot” where capital expenditure meets maximum efficiency for growing coffee brands.

Key Takeaway: Choosing a higher BPM early on prevents the need for a costly machine upgrade within the first two years of business.

5. How does packaging machine BPM reduce your cost per bag?

Packaging machine BPM lowers your cost per bag by spreading fixed operational costs over a much larger number of finished goods. When your machine runs faster, the “rent” and “insurance” cost assigned to each individual coffee bag drops. This allows you to offer more competitive wholesale prices while actually increasing your net profit.

Amortizing machine costs over higher volumes

Why does the math favor speed? Amortization is the process of paying off your equipment through the units it produces.

Look at the numbers:

- A $50,000 machine producing 1 million bags costs $0.05 per bag.

- That same machine producing 5 million bags costs only $0.01 per bag.

Energy efficiency and machine speed

Does a faster machine use more power? Modern high-BPM machines are designed to be more energy-efficient per unit than older, slower models.

Here is why it matters:

- Servo-driven motors in high-speed machines only use power when they are moving.

- You complete your daily production in 4 hours instead of 8, saving on facility lighting and climate control.

| Cost Component | Manual Packing | 60 BPM Machine |

|---|---|---|

| Labor Cost/Bag | High ($0.15+) | Low ($0.03) |

| Material Waste | 3-5% | <0.5% |

| Fixed Overhead | Diluted slowly | Diluted rapidly |

Analysis: Higher BPM turns your production line into a high-margin engine by slashing both variable and fixed costs per unit.

Key Takeaway: Speed is the most effective tool you have for protecting your margins against rising raw coffee and labor prices.

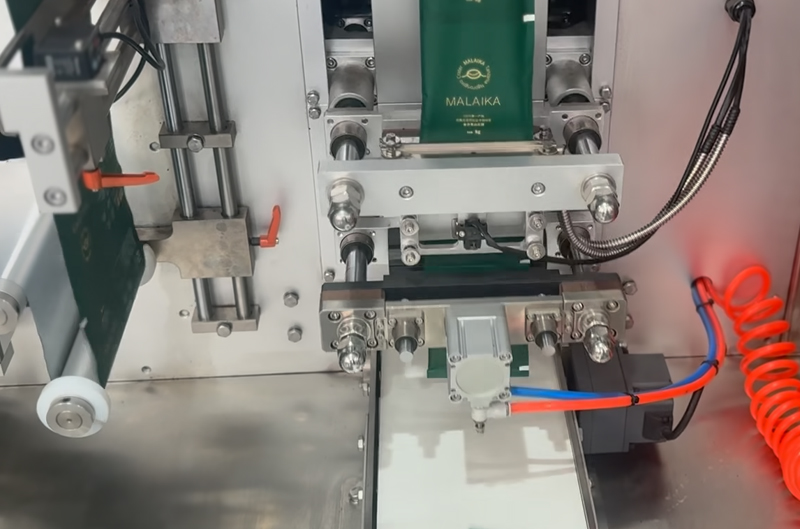

6. Why is ultrasonic tech vital for packaging machine BPM?

Ultrasonic technology is essential because it allows the packaging machine BPM to reach 60-90 units without the cooling delays required by traditional heat sealing. Unlike heat bars that need time to melt and then set the plastic, ultrasonic waves create a bond instantly. This allows the machine to move to the next cycle immediately, maximizing your uptime.

Eliminating heat-seal delays

Why is heat sealing the enemy of speed? Traditional heat sealing requires a “dwell time” where the bag remains stationary to ensure a strong bond.

But that’s not all:

- Ultrasonic sealing works through coffee dust, meaning fewer rejected bags due to seal failure.

- It prevents the “scorched” look on premium filter paper that occurs with slow heat sealers.

Ensuring seal integrity at high speeds

Can you trust a fast seal? At high BPM, precision is everything; ultrasonic tech provides a hermetic seal every single time without overheating the product.

Here is why it matters:

- The cold-sealing nature of ultrasonic tech preserves the volatile aromas of your coffee beans.

- You reduce downtime because there are no heating elements that need to be replaced or calibrated.

| Technology Type | Max Stable BPM | Seal Quality | Maintenance |

|---|---|---|---|

| Heat Sealing | 35-45 BPM | Medium (Risk of burn) | High (Heaters burn out) |

| Ultrasonic Sealing | 60-100+ BPM | High (Clean & Strong) | Low (Solid state) |

Analysis: Integrating ultrasonic sealing is the only way to achieve true industrial speeds without sacrificing the premium aesthetic of your drip bags.

Key Takeaway: Ultrasonic technology is the “engine” that makes high-speed ROI possible by removing the thermal limits of traditional packaging.

7. Does packaging machine BPM dictate your market competitiveness?

Packaging machine BPM determines your ability to compete for high-volume contracts with major retailers and hotel chains. If you can’t produce 100,000 bags a month, you simply won’t be considered by national distributors. Speed gives you the “ammunition” to win price wars and secure shelf space that slower competitors can’t touch.

Pricing strategies empowered by speed

How do the big brands stay so cheap? They use high-BPM machines to drive their costs so low that they can outprice boutique roasters while still making a profit.

Here is the secret:

- Speed allows for a “high volume, low margin” strategy that captures massive market share.

- You can offer tiered pricing to wholesalers because your internal cost is so predictable.

Winning the freshness race

Can speed improve taste? Yes, because high BPM allows you to pack coffee immediately after the degasification process is complete.

But that’s not all:

- You can fulfill “Just-in-Time” orders, ensuring your coffee arrives at the store within days of roasting.

- Faster packaging reduces the time the ground coffee is exposed to oxygen before being sealed in nitrogen.

| Competitive Edge | Low BPM Competitor | High BPM Leader (You) |

|---|---|---|

| Wholesale Pricing | $0.65/bag | $0.45/bag |

| Delivery Speed | 10 Days | 48 Hours |

| Freshness Index | Average | Premium |

Analysis: Market leadership is often a race of efficiency; the producer with the highest BPM usually dictates the market price.

Key Takeaway: Investing in speed is a strategic defensive move that prevents competitors from undercutting you on price or delivery time.

8. How to calculate ROI using your packaging machine BPM?

You calculate ROI by comparing the labor savings and increased revenue generated by your packaging machine BPM against the total cost of the equipment. A machine running at 60 BPM typically replaces 4 to 6 manual workers. When you factor in the reduction of waste and the ability to take on larger orders, the payback period is often under one year.

The 12-month ROI formula

Is a 12-month ROI realistic? For many roasters, the savings in labor alone cover the monthly lease or purchase payment of the machine.

Here is how you track it:

- Calculate your current labor cost per bag (Total Packing Wages / Total Bags).

- Subtract the new automated cost per bag (Machine Op Wage + Power / Total Bags).

- Multiply that saving by your annual volume.

Projecting long-term profitability

What happens after the machine is paid off? This is where your business truly scales, as every bag produced becomes pure profit minus the small cost of materials.

Think about the future:

- After month 12, your “production tax” (the machine cost) disappears.

- You can reinvest those savings into marketing, sourcing better beans, or buying a second machine.

| Investment Phase | Monthly Outflow | Monthly Revenue | Net Impact |

|---|---|---|---|

| Manual Phase | $8,000 (Wages) | $15,000 | +$7,000 |

| Machine Phase (Y1) | $2,500 (Lease) | $45,000 | +$42,500 |

| Post-ROI Phase (Y2+) | $0 (Paid off) | $45,000 | +$45,000 |

Analysis: The ROI of a high-speed machine is front-loaded; once you cross the break-even point, your profit margins expand dramatically.

Key Takeaway: Precision in calculating your BPM-based ROI allows you to make data-driven decisions about when to expand your facility.

9. Will high packaging machine BPM stabilize your labor expenses?

High packaging machine BPM stabilizes your labor expenses by making your production costs predictable regardless of wage hikes or labor shortages. Instead of managing a team of twelve people for packing, you manage one high-output machine and one operator. This decoupling of “output” from “headcount” is the only way to maintain a stable bottom line.

Automation as a hedge against rising wages

How do you survive a 20% increase in the minimum wage? You automate the most repetitive tasks so that wage increases only affect a tiny portion of your staff.

It’s a simple shift:

- One operator at a 60 BPM machine produces as much as a dozen manual packers.

- Training costs are reduced because you only need to educate one or two key employees.

Reducing human error and rework

Do you lose money on “bad bags”? Manual packing is prone to errors like poor seals, incorrect weights, and missing tags, all of which cost you money.

But that’s not all:

- Automated sensors check every bag for weight and seal integrity at 60 times per minute.

- Reducing rework (fixing bad bags) can save you up to 5% of your total production cost annually.

| Resource Type | Manual Packing Crew | High BPM Automated Line |

|---|---|---|

| Staff Count | 6-10 People | 1 Operator |

| Consistency | High Variance | 99.9% Precise |

| Scalability | Requires new hires | Requires a button press |

Analysis: Automation doesn’t just save money; it removes the “human variable” that makes scaling a business so difficult.

Key Takeaway: High BPM machines turn your labor from a variable, unpredictable expense into a fixed, manageable operational cost.

10. How to maintain peak packaging machine BPM for longevity?

Peak packaging machine BPM is maintained through a combination of daily preventative maintenance and proper operator training. If you treat your machine well, it will maintain its rated speed for a decade or more. Neglect, however, will lead to “micro-stops” that kill your hourly average and destroy your ROI.

Preventative maintenance schedules

Why is a clean machine a fast machine? Coffee dust is abrasive and oily; if it builds up in the moving parts, it creates friction that slows down the motor.

Here is the plan:

- Perform a 10-minute wipe-down at the end of every shift.

- Schedule monthly “deep cleans” to inspect belts, sensors, and ultrasonic heads.

Staff training for high-speed operation

Are your operators helping or hurting? An untrained operator might run the machine at 40 BPM because they are afraid of it breaking at 60 BPM.

But that’s not all:

- Proper training allows operators to troubleshoot minor issues without calling a technician.

- Working with a manufacturer that provides clear manuals and video support is vital for long-term speed.

| Maintenance Task | Frequency | Impact on BPM |

|---|---|---|

| Sensor Cleaning | Daily | Prevents false stops |

| Lubrication | Weekly | Maintains motor torque |

| Full Calibration | Quarterly | Ensures long-term accuracy |

Analysis: The “True BPM” of your facility isn’t what is on the spec sheet; it’s what you achieve through disciplined maintenance.

Key Takeaway: Longevity and speed are two sides of the same coin; a well-maintained machine is always the most profitable.

At newideapack, we believe that every roastery deserves the tools to compete on a global stage. Our vision is to empower coffee entrepreneurs with high-speed automation that transforms their passion into a scalable, high-margin reality.

- Can I start with a 30 BPM machine and upgrade later?

Yes, many roasters start with our entry-level models to establish their brand. However, choosing a 60 BPM machine from the start often prevents the secondary costs of facility reconfiguration and staff retraining during an upgrade. - What’s the best way to handle nitrogen flushing at high speeds?

The best way is to use a machine with an integrated nitrogen chamber that covers the entire filling and sealing process. This ensures that even at 80 BPM, the residual oxygen levels remain below 1% for maximum freshness. - How do I know if my volume justifies a high-speed machine?

If you are currently paying more than two employees to pack coffee for more than 4 hours a day, you have already reached the volume threshold where a high-speed machine will pay for itself. - Can I use eco-friendly filter papers on a high-BPM ultrasonic machine?

Absolutely. In fact, ultrasonic technology is actually better for eco-friendly materials because it creates a bond using vibration rather than high heat, which can sometimes degrade bio-degradable fibers. - How do I know if the machine is actually hitting its rated BPM?

Modern machines from newideapack include a digital dashboard that tracks “Real-Time BPM” and “Total Daily Output.” This allows you to monitor your ROI and operator efficiency with a single glance.

If you are ready to stop fighting bottlenecks and start scaling your business with precision

Contact us today for a customized production analysis.