Best Packaging Solution For Pasta, Beans & Rice

Best Packaging Solution For Pasta, Beans & Rice

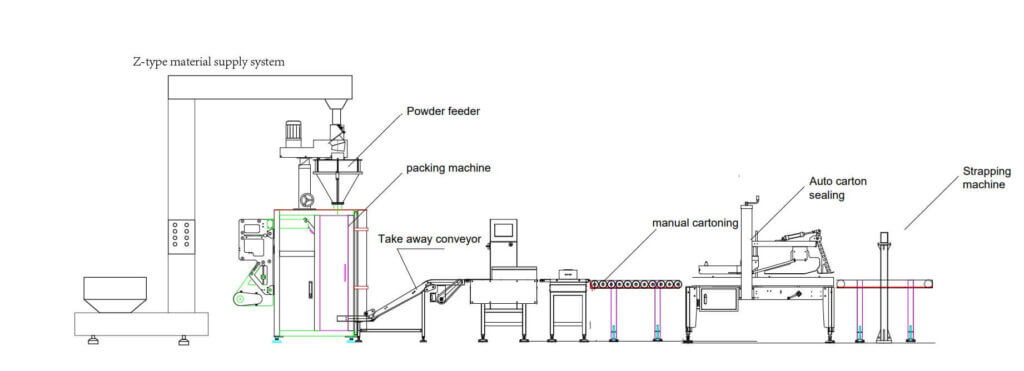

Are you still worried about packing a lot of coffee beans, spaghetti, and rice? Are you looking for a packaging machine that can weigh and package the above items quickly and accurately? Newideapack provides you with a perfect solution – a Z-type material supply system.

The biggest advantage of the Z-type material supply system is to solve the problem of heavy material supply when packaging coffee beans, pasta, rice, and other materials. It avoids the expenditure of additional human resource costs caused by heavy manual labor. Although there is similar mechanical equipment in the market, from a comprehensive point of view, the Z-type material supply system generated by Newideapack Ltd is the best. Here are some of the many advantages of our mechanical equipment.

Feature One:Adjustable Performance

1. The Z-type hoist can be combined into any height according to different packaging machines to meet different needs.

2. The feeding port of the hoist has a vibration function, and the amplitude is adjustable. The vibration amplitude can be adjusted according to the shape of the material, so as to meet the needs of blanking.

3. According to the volume of different hoppers, the Z-type elevator can supply 3-8 cubic meters of material to the packaging machine within one hour, and the feeding efficiency is very high.

Feature Two:High Precision Weighing And Filling System

Among the packaging solutions for pasta, beans and rice, it is possible to provide customers with a high-precision weighing and filling system: the multi-head combination electronic scale.

1. The error rate of the combined electronic scale is ±1%, so as to meet the accuracy requirements of customers for some high-value products.

2. The electronic scale can provide a configuration combination of 10 to 20 heads according to different weighing requirements and packaging speeds, and the filling speed according to different parameter settings, the fastest can reach 120 packets/min.

3. The multi-head electronic scale has built-in system parameters for different materials in the system, which is convenient to use.

4. In order to facilitate the daily cleaning of customers, the electronic scale can choose a waterproof configuration, which is convenient for washing.

https://youtu.be/UzuisvHVyrk

Feature Three: Expandability Of External Devices

As the core equipment in pasta, bean, and rice packaging solutions, Zhongyi Packaging’s fully automatic packaging machine can realize filling, forming, and packaging at one time.

1. According to the different product volumes of customers, we can provide customers with more than a dozen different packaging types of hosts to meet different packaging needs, you can click here to view.

2. The packaging speed of the automatic packaging machine is fast, and the maximum can reach 70 bags/min.

3. The host can be equipped with a nitrogen device, exhaust device, pin device, and other devices according to customer needs to meet various personalized needs.

4. The packaging machine adopts a human-computer interaction interface, PLC control, and the operation is convenient, fast, and intuitive.

Feature Four: Mature Product Conveying System

As the last subsystem of pasta, bean and rice packaging solutions, the product conveying system will complete the sorting and conveying process of products. The finished product conveyor belt lifts the product from the packaging machine to the rotating material handling plate, and completes the final inspection and packing on the material handling plate.