ND-C80Pro Automatic Drip Coffee Bag Packaging Machine

ND-C80ProWhether you're a specialty coffee roaster, private label supplier, or OEM partner, ND-C80Pro is built to meet your goals.

| Packing Speed: | 80-90 bags/min |

| Filling Range: | 8-12g |

| Inner Bag Size: | 90×75mm/80×100mm |

| Outer Bag Size: | 100×125mm/110×130mm |

Features Of Drip Bag Coffee Packaging Machine

- 1 The machine can complete bag-making, measuring, filling, sealing, cutting, counting, printing QR code, nitrogen filling function and other functions.

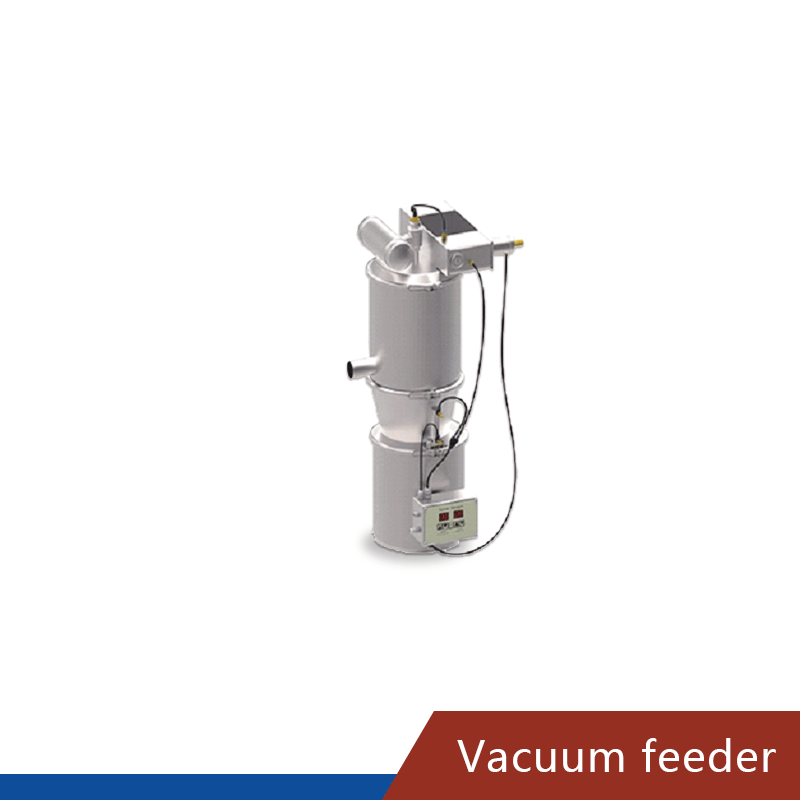

- 2 The machine structure is open type, convenient for debugging, monitoring, clean, and man-machine interface operation.

- 3 Adopt Mitsubishi PLC, multi-language touch screen controlling, main power by servo system, easy operation, high efficiency.

- 4 In Strict detection, the equipment will stop under the conditions of no material, empty inner bag, empty outer bag, no film, insufficient air pressure, temperature deviation and so on, to greatly reduce the output of defective products.

- 5 The inner bag length is driven by a servo motor, positioning is accurate and the bag length is stable.

- 6 The outer bag adopts the form of servo motor pulling film, which is more smooth and fast than the traditional pulling film wheel type. Shaper using five axes machining center precision processing, can be applied to most of the different material film, and the production of bag smooth natural, no pull marks, wrinkles and other defects.

- 7 Independent inner bag production mode, can realize one machine multi-purpose, users can according to the needs of the production of lug inner bag, filter paper inner bag, inner and outer bag three different types of products.

- 8 The feeding system of this machine has the advantages of simple adjustment, high measuring accuracy, and easy to clean, which effectively solves the cleaning problem caused by frequent replacement of materials in the production process.

If you want to lock in the original aroma of drip coffee to the greatest extent and let your customers enjoy the mellow taste of freshly ground coffee in every cup, choosing the ND-C80Pro drip coffee bag packaging machine is the best choice. For nitrogen-filled freshness preservation of drip coffee bags, you must choose the ND-C80Pro drip coffee bag packaging machine.

Technical Parameters Of Drip Bag Coffee Packaging Machine

| Parameter | Specification |

|---|---|

| Packing Speed | 80-90 bags/min |

| Filling Range | 8-12g |

| Inner Bag Size | 90×75mm/80×100mm |

| Outer Bag Size | 100×125mm/110×130mm |

| Sealing Method | Heat sealing |

| Air Pressure | 0.6-1 MPa |

| Total Power | 220V/380V、50Hz/60Hz 3.5kW |

| Weight | 1200kg |

| Dimensions | 1761×1194×2960mm |

Bag Type Of Drip Bag Coffee Packaging Machine

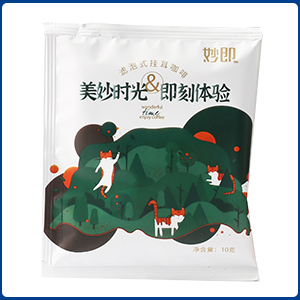

Inner bag: Drip coffee bag,drip tea bag, flat bag with or without tag and thread.

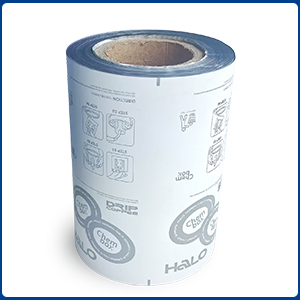

Inner bag packaging material: Can made of non-woven fabric, PET mesh, corn fiber environmental protection material,etc.

Outer envelope: Three-side sealing(a variety of easy tear are available)

Outer envelope packaging material: BOPP/AL/LDPE ,T/VMPET,PET/CPP Etc. Multiple heat-sealable composite packaging materials are available.

Related bag types

Sample bag

Applications Of Drip Bag Coffee Packaging Machine

ND-C80Pro drip coffee packaging machine can pack drip coffee bag with outer envelope with nitrogen filling to extend the shelf life. This makes it possible for some cafes and ground coffee manufacturers to sell more coffee around the world.

The advanced nitrogen filling technology ensures that the coffee remains fresh for an extended period, preserving its aroma and flavor. This packaging solution is ideal for businesses looking to expand their market reach while maintaining product quality.

Machine Operation Demonstration

FAQ Of Drip Bag Coffee Packaging Machine

What is the sealing method of the drip coffee bag packaging machine?

Inner drip bag is ultrasonic sealing, outer bag is heat sealing.

Why use ultrasonic sealing method for the drip coffee bag.

1,Different packaging materials.

2,The sealing principle is different.

3,The edge banding is different.

4,The packaging machine is different.

If you want to extend the fresh-keeping period of drip coffee while maintaining its top-tier flavor, and let customers recognize your product’s quality, choosing the ND-C80Pro drip coffee bag packaging machine is the best choice.

Media Of Drip Bag Coffee Packaging Machine

Automatic Drip Coffee Bag Packaging Machine

ND-C80Pro AUTOMATICDRIP COFFEE BAGPACKAGING MACHINEOVERVIEW

ND-C80Pro ...

Get Free Quote

We'd be happy to introduce you personally about our products and solutions. Call us or let us call you back at a convenient time for you.

Custom Packaging Machine With Ease

At newideapack, We tum complex Into Simple! Follow the following 3 steps to start today!

1.Tell Us What You Need

Tell us as specifc as possible of your needs, provide thedrawing, reference picture and share your idea.

2.Get Solution & Quote

We will work on the best solution according to your requirements and drawing, the specific quote will be provided within 24 hours.

3.Approve for Mass Production

We will start mass production after getting your approval and deposit, and we will handle the shipment.

📞 Call immediately

Phone: +86-13920157717

WhatsApp:+86-13920157717