Auger vs. Volumetric Filling: How to Choose the Precision Dosing System

When scaling a roastery, choosing between Auger vs. Volumetric Filling is the most critical decision for maintaining product integrity. While both systems aim to automate your line, they handle coffee grinds differently; using the wrong method leads to product giveaway and inconsistent flavor profiles. This guide breaks down how to choose the right precision dosing system to eliminate inaccuracy and protect your profit margins.

Why is coffee powder dosing accuracy so critical for your ROI?

Inconsistent coffee powder dosing directly erodes your bottom line by wasting expensive raw materials. If you produce 10,000 bags daily and overfill by just 0.5g, you lose 5kg of premium coffee every shift. Precision ensures that you sell exactly what you promise without sacrificing your profit margins.

Think about it.

- Reduced Giveaway: Keeping weights tight to the target prevents product loss.

- Compliance: Avoiding underfills protects you from legal weights and measures issues.

- Batch Uniformity: Consistent dosing ensures every customer gets the same flavor profile.

Does weight variation affect your brand’s reputation?

A customer expects a specific strength in their morning cup. If your dose varies, the taste profile changes, leading to a perceived lack of quality control. This inconsistency drives loyal fans toward your competitors.

How do accurate fills impact long-term scalability?

Scalable roasteries rely on predictable material usage and output. When your dosing is precise, you can accurately forecast inventory and revenue. This stability is essential for securing large-scale retail contracts.

Key Takeaway: Precise dosing is not just a technical requirement; it is a financial strategy to maximize yield and brand trust.

| Dosing Accuracy | Annual Product Loss (Est.) | Brand Impact |

|---|---|---|

| ±0.5g | High (1.5+ Tons) | Negative |

| ±0.2g | Medium | Neutral |

| ±0.1g (Precision) | Minimal | Excellent |

High-precision dosing minimizes “giveaway” coffee, significantly increasing the net profit per production run.

How does an auger filler improve coffee powder dosing precision?

An auger filler uses a vertical screw driven by a servo motor to achieve high-precision coffee powder dosing. This mechanical “push” is ideal for fine, non-free-flowing powders like espresso or Turkish grinds that tend to clump. The rotating action breaks down clumps to ensure a dense, repeatable volume.

Here is the thing:

- Servo Control: Allows for infinite digital adjustment of the screw revolutions.

- Dust Containment: Enclosed funnels prevent fine powder from drifting during fill.

- Mechanical Force: Effectively handles “sticky” powders that gravity systems cannot.

What is the mechanical secret of the auger screw?

The screw displaces a specific volume of product with every 360-degree rotation. By controlling the exact degree of rotation via digital pulses, the machine delivers a consistent weight regardless of minor flow changes.

Why is auger filling best for ultra-fine grinds?

Ultra-fine coffee particles often create “bridges” in standard hoppers, leading to empty fills. The auger’s agitator blade keeps the product moving, ensuring the screw is always fully charged for the next dose.

Key Takeaway: Auger fillers provide the mechanical control necessary for difficult, fine powders where gravity-based systems often fail.

| Mechanism | Suitability | Accuracy Level |

|---|---|---|

| Auger Screw | Non-free-flowing | Very High |

| Gravity Feed | Free-flowing only | Low |

| Vibration Assist | Granular | Moderate |

Servo-driven auger systems eliminate the unpredictability of manual dosing by digitizing the physical movement of the coffee.

Is volumetric cup filling better for high-speed coffee powder dosing?

Volumetric cup filling is the gold standard for high-speed coffee powder dosing when handling medium-to-coarse grinds. These systems use fixed-volume cups that fill by gravity as they rotate under a product hopper. Because the mechanism is simpler than an auger, it can reach significantly higher cycle speeds without losing stability.

The result?

- High Throughput: Reaches speeds of 60+ bags per minute easily.

- Low Maintenance: Fewer moving parts mean less downtime for repairs.

- Quick Cleaning: Stainless steel cups are easily accessible for sanitation.

How do telescopic cups allow for volume adjustments?

Modern volumetric systems feature telescopic cups that expand or contract to change the internal volume. You can fine-tune your weight while the machine is running, saving valuable calibration time.

Is volumetric filling suitable for all drip coffee grinds?

Yes, most drip coffee grinds fall into the medium-coarse category which flows perfectly into cups. The uniform particle size ensures that the density remains consistent enough for volumetric measurement to equal precise weight.

Key Takeaway: For roasteries focused on high-volume drip bag production, volumetric cup filling offers the best combination of speed and repeatability.

| Feature | Volumetric Cup | Typical Output (BPM) |

|---|---|---|

| Adjustment | Telescopic (Manual/Auto) | 50 – 80 |

| Complexity | Low | N/A |

| Cost | Economical | N/A |

Volumetric dosing excels in environments where speed is the primary KPI and the grind size remains consistently coarse.

How do density changes impact your coffee powder dosing results?

Density fluctuations are the primary cause of coffee powder dosing errors in both volumetric and auger systems. Dark roasts are physically larger and lighter (less dense) than light roasts due to the expansion during roasting. If you switch beans without recalibrating your machine, your final bag weights will drift significantly.

Best of all?

- Roast Awareness: Dark roasts require larger volumes to reach the same weight.

- Humidity Control: Moisture makes powder stickier, changing its flow density.

- Degassing: Freshly ground coffee contains CO2 which can “fluff” the product and alter volume.

How does moisture affect the flow of ground coffee?

High humidity increases the static charge and stickiness of the coffee oils. This can cause the powder to cling to the sides of dosing cups, resulting in underfilled bags.

Why does roast level change your machine settings?

A light roast is dense and heavy, meaning a small cup volume is required. Conversely, a dark oily roast takes up more space, requiring you to increase the cup size or auger revolutions.

Key Takeaway: Constant monitoring of your product’s bulk density is required to maintain dosing accuracy across different roasts and batches.

| Roast Level | Bulk Density | Dosing Requirement |

|---|---|---|

| Light Roast | High | Smaller Volume |

| Medium Roast | Moderate | Standard Volume |

| Dark Roast | Low | Larger Volume |

Understanding the physical properties of your roast allows you to preemptively adjust dosing parameters and avoid wasted production time.

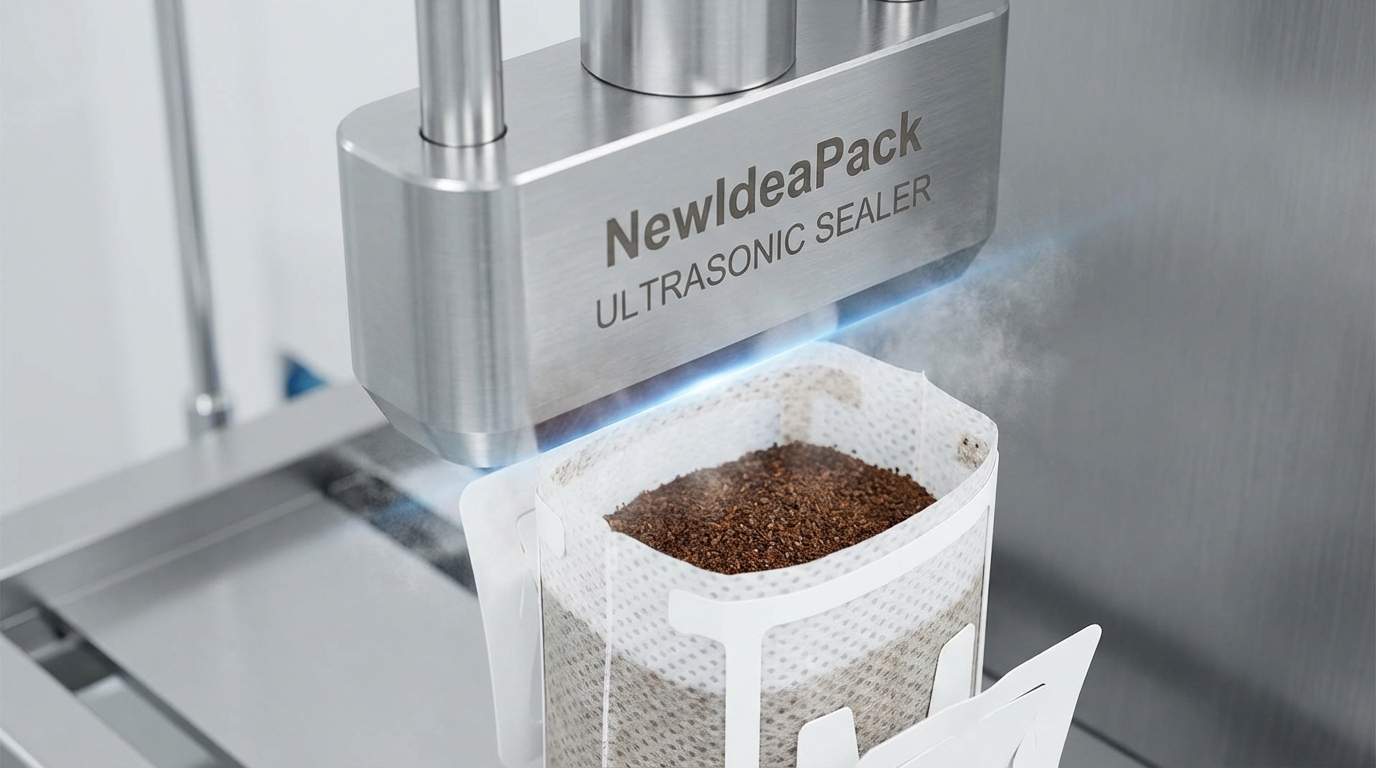

Does Newidea Pack use volumetric filling for coffee powder dosing?

Newidea Pack utilizes advanced volumetric filling for coffee powder dosing specifically in their drip coffee bag machines. This choice is driven by the industry’s need for high-speed output and the consistent grind profile of drip coffee. Our volumetric systems are engineered to achieve ±0.1g to ±0.2g accuracy at speeds exceeding 50 bags per minute.

It gets better.

- Precision Machining: Cups are crafted with tight tolerances to prevent powder leakage.

- Vibration Assist: Helps settle the powder in the cup for a more consistent density.

- Food-Grade Material: All contact parts use high-quality SUS304 stainless steel.

Why does Newidea Pack favor volumetric for drip bags?

Drip bag consumers prioritize convenience and high-speed production keeps costs low. Volumetric dosing provides the necessary reliability to run 24/7 without the complex calibration required by high-end augers.

How does Newidea Pack ensure long-term machine stability?

By using robust mechanical linkages and high-quality sensors, our machines maintain their calibration even after millions of cycles. This engineering focus minimizes the “drift” often seen in cheaper volumetric systems.

Key Takeaway: Newidea Pack specializes in volumetric dosing for drip coffee to provide customers with a balance of industrial speed and leading weight precision.

| Brand Component | Newidea Pack Standard | Competitor Average |

|---|---|---|

| Dosing Precision | ±0.1g | ±0.5g |

| Frame Material | SUS304 | Painted Steel |

| Sealing Type | Ultrasonic | Heat Only |

Choosing a manufacturer that prioritizes volumetric precision ensures your drip bag line remains both fast and highly profitable.

Can servo motors eliminate coffee powder dosing errors entirely?

Integrating servo motors into your coffee powder dosing system provides the digital precision needed to virtually eliminate mechanical errors. Unlike standard AC motors, servos allow for precise control over acceleration, deceleration, and the exact position of the dosing screw or cup. This level of control compensates for the natural variability in coffee flow and density.

That’s not all.

- Feedback Loops: Servos can communicate with the PLC to correct errors in real-time.

- Consistent Torque: Ensures the dosing screw turns with the same force every time.

- High Resolution: Digital encoders track thousands of positions per single rotation.

How does digital control fix weight drifting issues?

When integrated with a checkweigher, the servo motor can automatically increase or decrease its rotation speed if it detects a weight trend. This creates a self-correcting system that requires minimal operator intervention.

Can servo motors handle different grind sizes automatically?

Yes, you can save “recipes” in your Newidea Pack PLC. When you switch from a coarse drip grind to a finer espresso, the servo automatically adjusts its parameters for optimal flow.

Key Takeaway: Servo motors transform dosing from a manual guessing game into a precise, automated process that protects your product quality.

| Motor Type | Control Precision | Self-Correction Ability |

|---|---|---|

| Standard AC | Low | None |

| Stepper | Medium | Limited |

| Servo Motor | Extremely High | Automated |

Servo technology is the most effective tool for modern roasteries to maintain tight tolerances across high-speed production lines.

Which filling method reduces waste in coffee powder dosing?

Selecting the right filling method is the most effective way to reduce waste in coffee powder dosing. For free-flowing medium grinds, volumetric cups are highly efficient at minimizing “dusting” and spill-over. For ultra-fine powders, the auger’s enclosed design prevents product from escaping into the environment, keeping your facility clean and your product in the bag.

Why does this matter?

- Sealing Integrity: Precise dosing prevents powder from contaminating the seal area.

- Product Recovery: Enclosed systems ensure every gram of coffee reaches the package.

- Reduced Cleanup: Less airborne dust means less downtime for machine sanitation.

How do inaccurate fills lead to sealing failures?

If the dosing system “splashes” powder into the top of the bag, the heat or ultrasonic sealer cannot create a bond. This leads to leakers, flat bags, and significant wasted material.

Can precision dosing pay for the machine itself?

Yes. By reducing “giveaway” from 0.5g to 0.1g per bag, a high-volume roastery can save enough coffee to pay for a Newidea Pack machine within the first year of operation.

Key Takeaway: Waste reduction is a direct result of choosing a dosing method that matches the physical characteristics of your coffee grind.

| Waste Source | Mitigation Strategy | Efficiency Gain |

|---|---|---|

| Overfilling | Precision Volumetric Cup | High |

| Seal Contamination | Ultrasonic Sealing | Very High |

| Airborne Dust | Enclosed Auger Feed | Moderate |

Reducing product waste not only lowers your material costs but also improves the overall hygiene and uptime of your packaging facility.

How to calibrate machines for consistent coffee powder dosing?

Regular calibration is the only way to ensure coffee powder dosing remains accurate over long production shifts. Environmental factors like temperature and humidity can alter the way coffee flows through the machine. You should perform a weight verification test every four hours and after every batch change to confirm the system is performing within tolerance.

Here’s why:

- Environmental Drift: Heat can make coffee oils more viscous, slowing down the flow.

- Component Wear: Dosing screws or cups can develop minor pitting over time.

- Operator Skill: Proper training ensures that calibration is performed consistently.

What are the daily maintenance steps for dosing units?

You must clean the internal surfaces of the dosing cups or auger screw daily to remove residual oils. These oils can trap fine powder, slowly changing the internal volume and degrading accuracy.

When should you perform a full system recalibration?

A full recalibration is necessary whenever you change suppliers or significantly alter your roasting profile. Different bean origins have unique cell structures that impact how they grind and flow.

Key Takeaway: Calibration is a proactive habit that separates professional roasteries from those struggling with inconsistent product quality.

| Calibration Task | Frequency | Expected Result |

|---|---|---|

| Weight Check | Every 4 Hours | Weight Stability |

| Oil Removal | Daily | Prevents Volume Drift |

| Sensor Check | Monthly | System Reliability |

A well-maintained and calibrated dosing system is the foundation of a reliable, high-output coffee packaging operation.

Should you choose auger or volumetric for coffee powder dosing?

The choice between auger and volumetric coffee powder dosing depends entirely on your product’s flow characteristics and your budget. Auger fillers offer the highest precision for fine powders but are more expensive and complex to maintain. Volumetric cup fillers are simpler, faster, and more cost-effective for standard drip coffee grinds.

The truth?

- Espresso/Fine: Choose an Auger Filler for superior compression and accuracy.

- Drip/Coarse: Choose Volumetric Cup Filling for maximum speed and ROI.

- Multipurpose: Some machines can be retrofitted, but dedicated heads are always more accurate.

Which system is easier for your operators to manage?

Volumetric systems are generally more “set and forget.” Once the telescopic cups are adjusted for a specific grind, they require very little digital monitoring compared to servo-auger systems.

How does grind size dictate your final choice?

Fine grinds have a lot of internal friction and don’t flow well under gravity, requiring an auger. Coarse grinds behave more like granules, making them perfect for the fast-rotating cups of a volumetric filler.

Key Takeaway: Match your machine to your most common grind profile to ensure you get the best performance for your investment.

| Factor | Auger Filler | Volumetric Cup |

|---|---|---|

| Ideal Product | Fine Powder | Coarse/Medium Grind |

| Speed Priority | Accuracy Focus | Throughput Focus |

| Maintenance | High | Low |

Choosing the correct dosing technology prevents the frustration of trying to force a machine to handle a product it wasn’t designed for.

How does Newidea Pack optimize coffee powder dosing for drip bags?

Newidea Pack optimizes coffee powder dosing by integrating the dosing unit directly with our ultrasonic sealing technology. By synchronizing the fill cycle with the sealing jaw movement, we ensure that no powder is suspended in the air when the bag is closed. This prevents seal contamination and ensures a perfect, airtight package every time.

The bottom line:

- Integrated Logic: The PLC manages the entire cycle to prevent timing errors.

- Nitrogen Flushing: Dosing occurs in a controlled atmosphere to preserve aroma.

- Static Elimination: Anti-static bars ensure powder doesn’t cling to the filter paper.

What makes Newidea Pack a global standard for drip coffee?

Our machines are used by leaders like Pascucci because they deliver 55+ bags per minute with industrial-grade stability. We focus on the small details, like vibration-assisted cups, that other manufacturers overlook.

Can modular dosing systems future-proof your roastery?

Yes, Newidea Pack equipment is designed for modularity. You can start with a volumetric system and upgrade to more advanced sensors or feedback loops as your production volumes grow.

Key Takeaway: Optimization is achieved through the perfect synchronization of dosing, nitrogen flushing, and ultrasonic sealing in a single automated system.

| Optimization Feature | Benefit | Business Result |

|---|---|---|

| Ultrasonic Sealing | No powder leaks | Professional Brand Image |

| Nitrogen Injection | 12+ Month Shelf Life | Global Distribution |

| Modular Dosing | Scalable Production | Long-term ROI |

Investing in a Newidea Pack system means choosing a partner that understands the intricate relationship between dosing precision and coffee freshness.

*

Conclusion

The battle against inaccuracy in coffee powder dosing is won by selecting the technology that fits your specific roast and grind. Whether you require the high-speed efficiency of Newidea Pack’s volumetric cup systems for drip coffee or the forced-displacement precision of an auger for fine espresso, the goal remains the same: protecting your profit margins. Don’t let inconsistent weights erode your brand value and waste your hard-earned revenue. Invest in precision-engineered machinery to ensure every bag is a perfect representation of your roast.

FAQ

Can I use one machine for both whole beans and powder?

No, you generally cannot use the same dosing head for both. Coffee powder dosing requires an auger or volumetric cup, while whole beans typically require a linear or multi-head weigher to prevent crushing the beans.

What’s the best dosing method for ultra-fine espresso grinds?

The best method for ultra-fine grinds is an Auger filler. The mechanical screw prevents the powder from “bridging” or clumping, which is a common failure point for gravity-fed volumetric systems.

Can I switch between auger and volumetric systems on the same machine?

Yes, most Newidea Pack machines are designed with modularity in mind. While it requires a change-over kit and a PLC update, we can help you transition your machine as your product line expands.

What’s the best way to handle oily dark roasts?

The best way is to use a volumetric system with a vibration-assisted feeder. The vibration helps the oily particles move smoothly and settle evenly into the dosing cups for a consistent weight.

Can I integrate a checkweigher with my dosing unit?

Absolutely. Integrating a checkweigher with a servo-driven dosing unit creates a “closed-loop” system. If a bag is off-weight, the machine automatically adjusts the next dose to compensate, virtually eliminating manual errors.

Ready to eliminate dosing errors and scale your coffee production?

Contact us today for a customized production analysis and machine quote.