5 Reasons Why Servo Motors are Critical for Speed

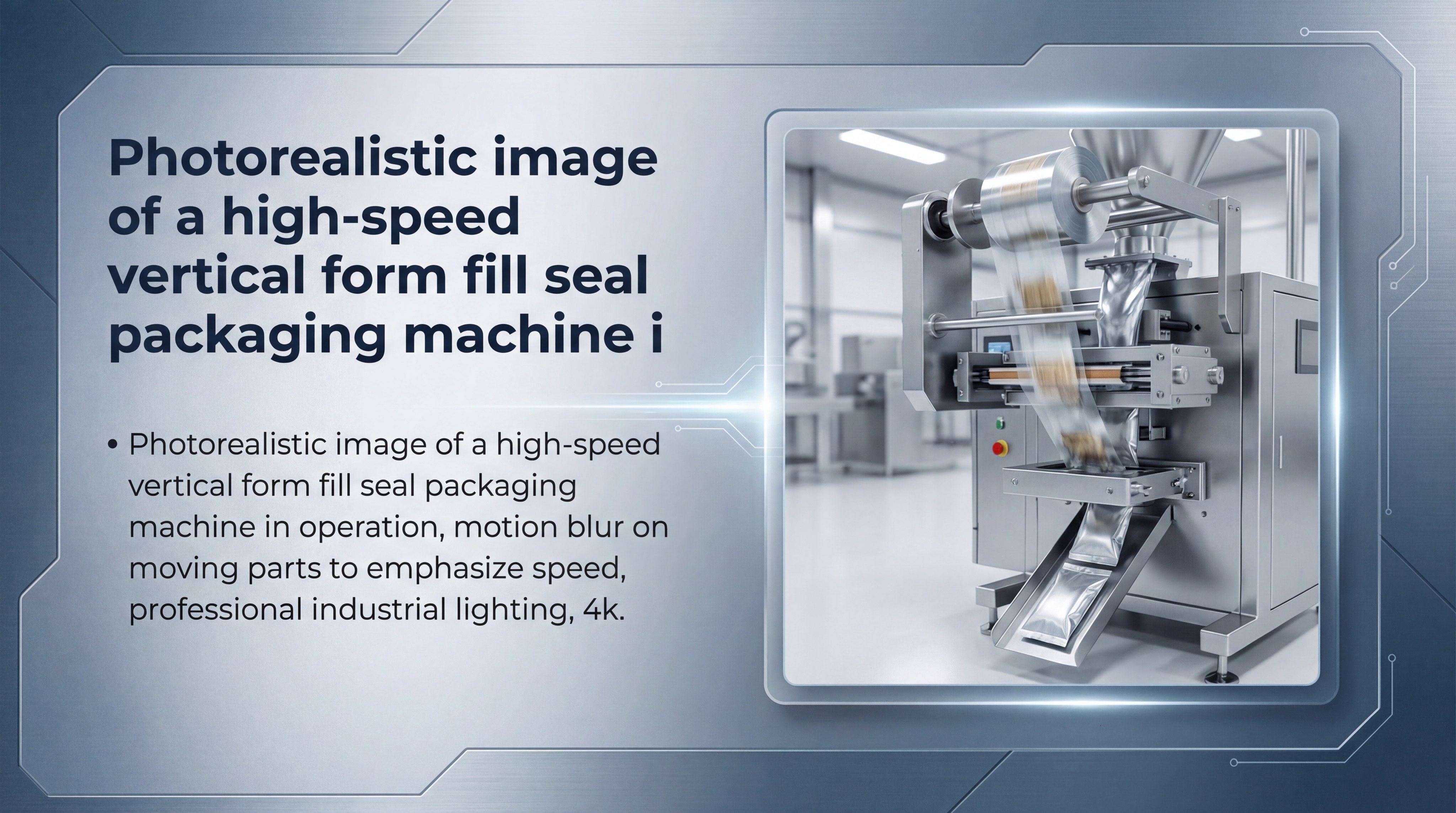

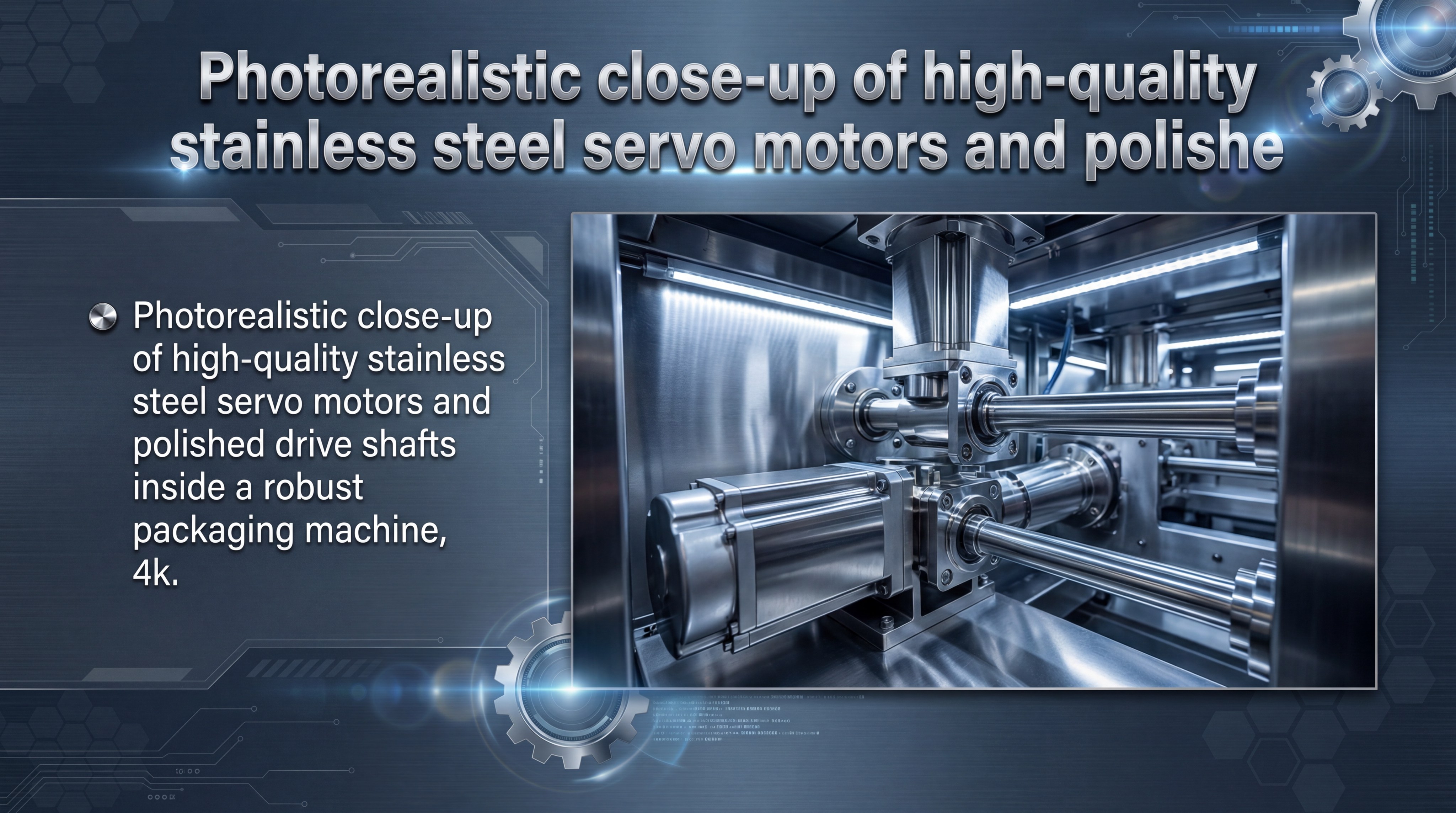

Servo motors are critical for speed because they provide high-torque acceleration and precise closed-loop feedback that eliminates the mechanical delays inherent in traditional drive systems. Imagine your production line coming to a sudden halt because a mechanical cam slipped or a belt stretched, throwing your entire timing out of sync. This downtime doesn’t just stall your output; it actively erodes your ROI and pushes your delivery schedules into the red. By upgrading to a modern servo motor packaging machine, you replace unpredictable mechanical linkages with digital precision that ensures maximum throughput. Newideapack provides these advanced solutions to help you maintain a competitive edge in a high-demand market.

Why is a servo motor packaging machine faster?

A servo motor packaging machine achieves higher speeds by utilizing electronic synchronization instead of physical chains or gears. This digital architecture allows for instantaneous adjustments to the machine’s cycle, ensuring that every movement is optimized for the shortest possible duration.

How does digital control improve cycle rates?

Digital control improves cycle rates by allowing the motor to reach peak velocity almost instantly. Unlike induction motors that require a ramp-up period, servos provide high torque at the start of the motion.

You might be surprised by how much time is lost during “ramping” in older systems.

- Faster acceleration phases.

- Minimal dwell time between cycles.

- Real-time adjustment to material resistance.

Can independent axis control reduce bottlenecks?

Independent axis control reduces bottlenecks by allowing different parts of the machine to move at varying speeds simultaneously. This means the filling station doesn’t have to wait for the entire mechanical drivetrain to finish a rotation before starting its next task.

It gets even better when you look at the total output.

- Overlapping operations increase PPM (parts per minute).

- Individual stations can be tuned for maximum efficiency.

- Reduced interference between mechanical components.

Key Takeaway: A servo motor packaging machine eliminates mechanical lag, allowing for overlapping movements that significantly boost your total parts per minute.

| Feature | Impact on Speed |

|---|---|

| Electronic Sync | Eliminates mechanical friction and delay |

| High Torque | Faster start/stop cycles |

| Digital Feedback | Real-time speed correction |

The transition from mechanical to digital synchronization is the primary driver behind the double-digit increases in production speed seen in modern facilities.

Does a servo motor packaging machine improve accuracy?

A servo motor packaging machine improves accuracy by using high-resolution encoders to track the exact position of the motor shaft thousands of times per second. This constant monitoring ensures that even at high speeds, the machine never loses its place or deviates from the set parameters.

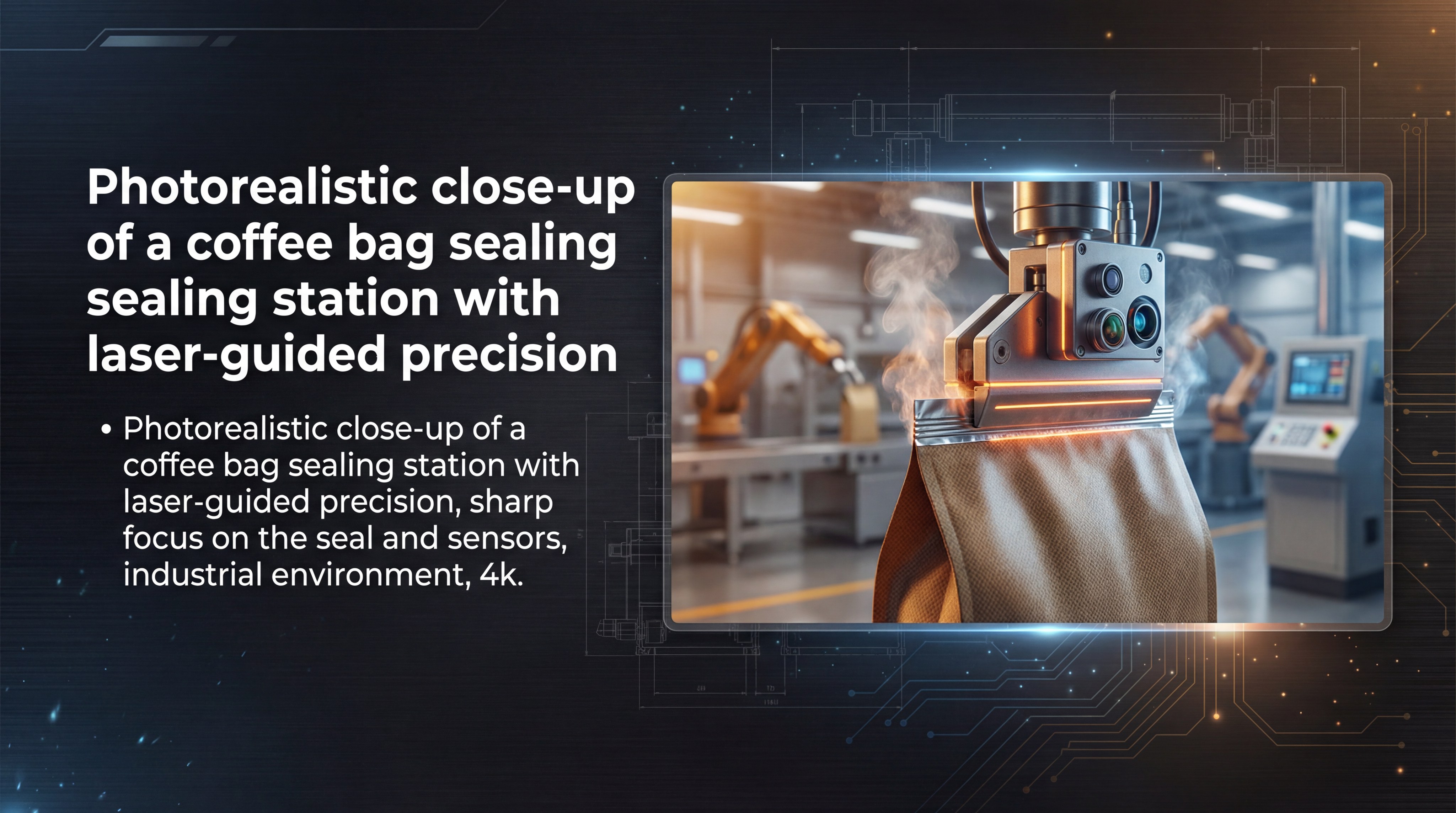

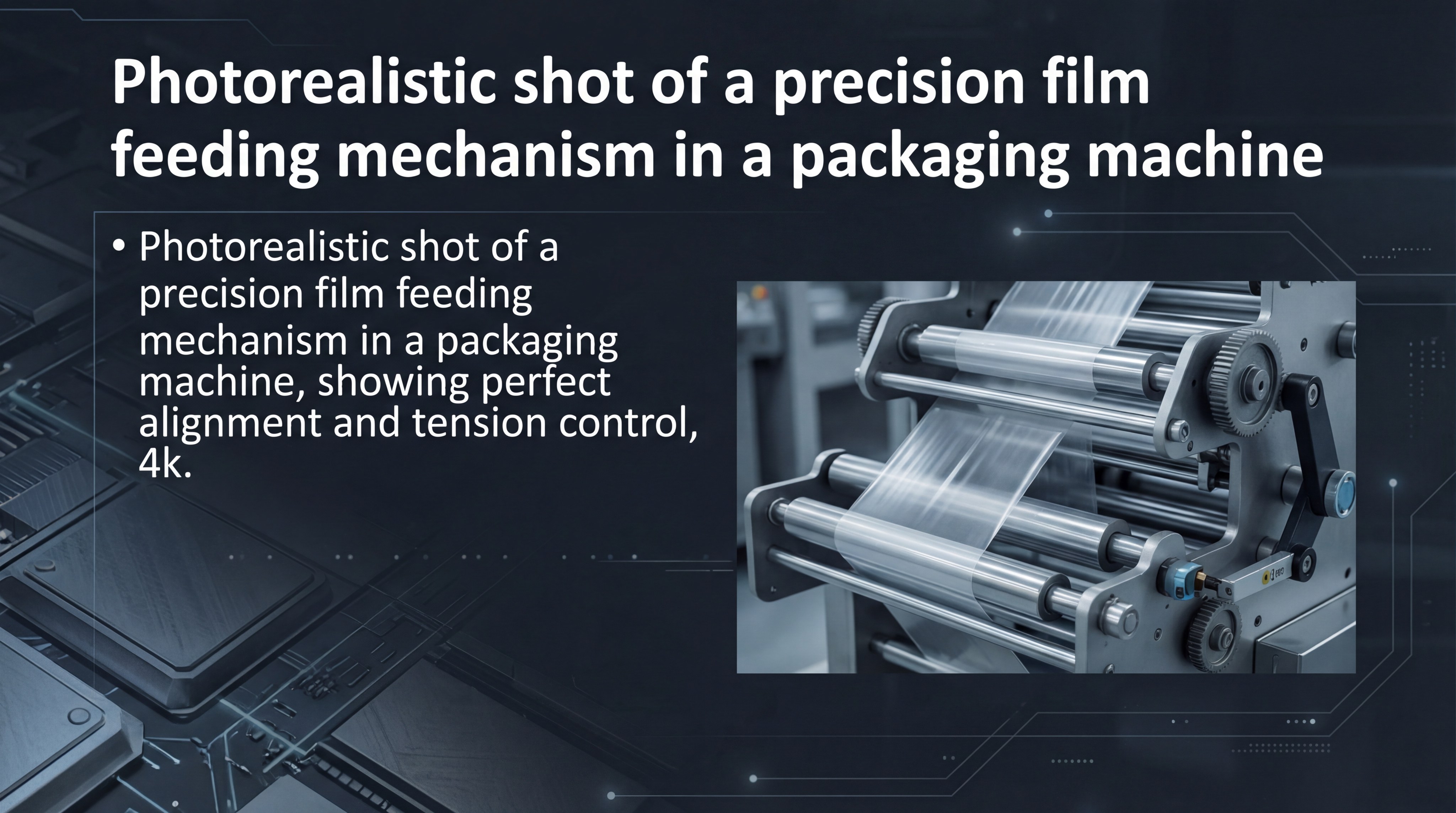

How does precise positioning impact film feeding?

Precise positioning ensures that the packaging film is pulled to the exact millimeter required for every sachet. This prevents the “drift” that often occurs with friction-based feeding systems, which can lead to wasted material or misaligned graphics.

But wait, there’s more to consistency than just length.

- Consistent bag lengths.

- Reduced strain on the film material.

- Perfect alignment for sealing jaws.

Why is registration mark detection more reliable?

Registration mark detection is more reliable because the servo can adjust the film position mid-cycle based on optical sensor input. This means if the film stretches slightly, the motor compensates instantly to keep the print centered.

Think about it: high speed with zero waste.

- No more “runaway” print errors.

- Automatic correction at full production speed.

- Higher aesthetic quality for your brand.

Key Takeaway: High-resolution tracking ensures that your speed never comes at the cost of precision, protecting both your material costs and your brand image.

| Accuracy Factor | Benefit |

|---|---|

| Encoder Resolution | Sub-millimeter positioning |

| Real-time Correction | Zero-drift operation |

| Visual Integration | Perfect print registration |

Accuracy and speed are no longer a trade-off; with servo technology, they function as complementary forces to improve your bottom line.

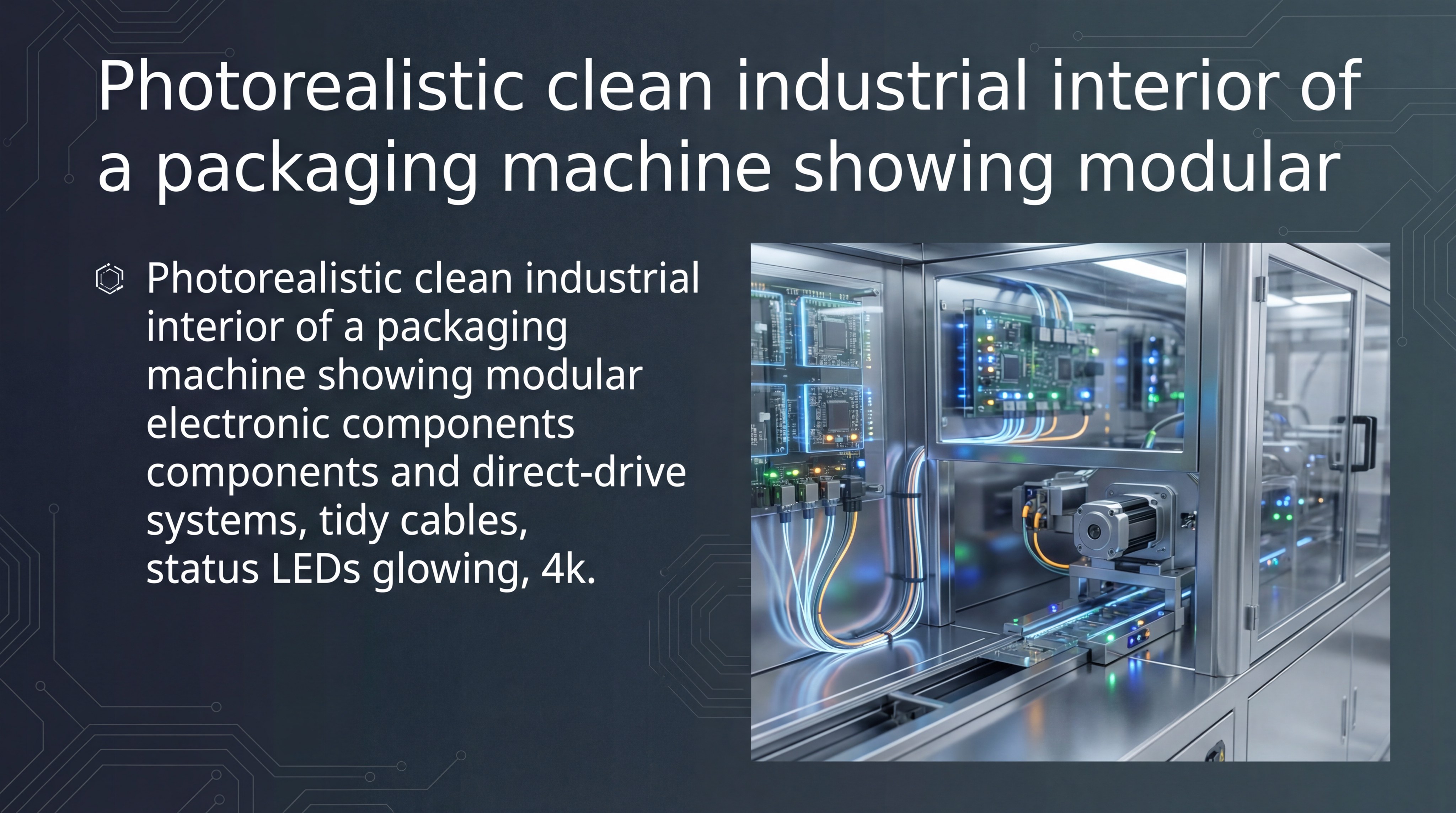

Can a servo motor packaging machine reduce downtime?

A servo motor packaging machine reduces downtime by replacing wear-prone mechanical parts with solid-state electronics and direct-drive systems. Fewer moving parts mean there are fewer components to fail, lubricate, or adjust during a production shift.

Does fewer mechanical parts mean less maintenance?

Fewer mechanical parts directly translate to less maintenance because you no longer need to manage complex assemblies like timing belts, cams, and pulleys. These components are the most frequent causes of mechanical failure in older packaging equipment.

Here is the deal: less time wrenching, more time packing.

- Less grease and oil contamination.

- Reduced spare parts inventory requirements.

- Longer intervals between scheduled service.

How do automated changeovers save production hours?

Automated changeovers save hours by allowing you to switch product recipes via a touchscreen interface rather than manual tool adjustments. The servo motors automatically move to their new designated positions for the different bag sizes or fill volumes.

It gets better when you have multiple SKUs.

- Changeover times reduced from hours to minutes.

- Elimination of human error during setup.

- Consistent results every time you switch products.

Key Takeaway: By minimizing physical wear and automating setups, you maximize the “uptime” of your production line, leading to a much higher daily output.

| Downtime Factor | Servo Solution |

|---|---|

| Component Wear | Direct-drive electronics |

| Manual Tuning | Recipe-based automation |

| Diagnostics | On-screen error reporting |

The reduction in mechanical complexity is perhaps the most significant long-term cost-saving feature of investing in servo-driven equipment.

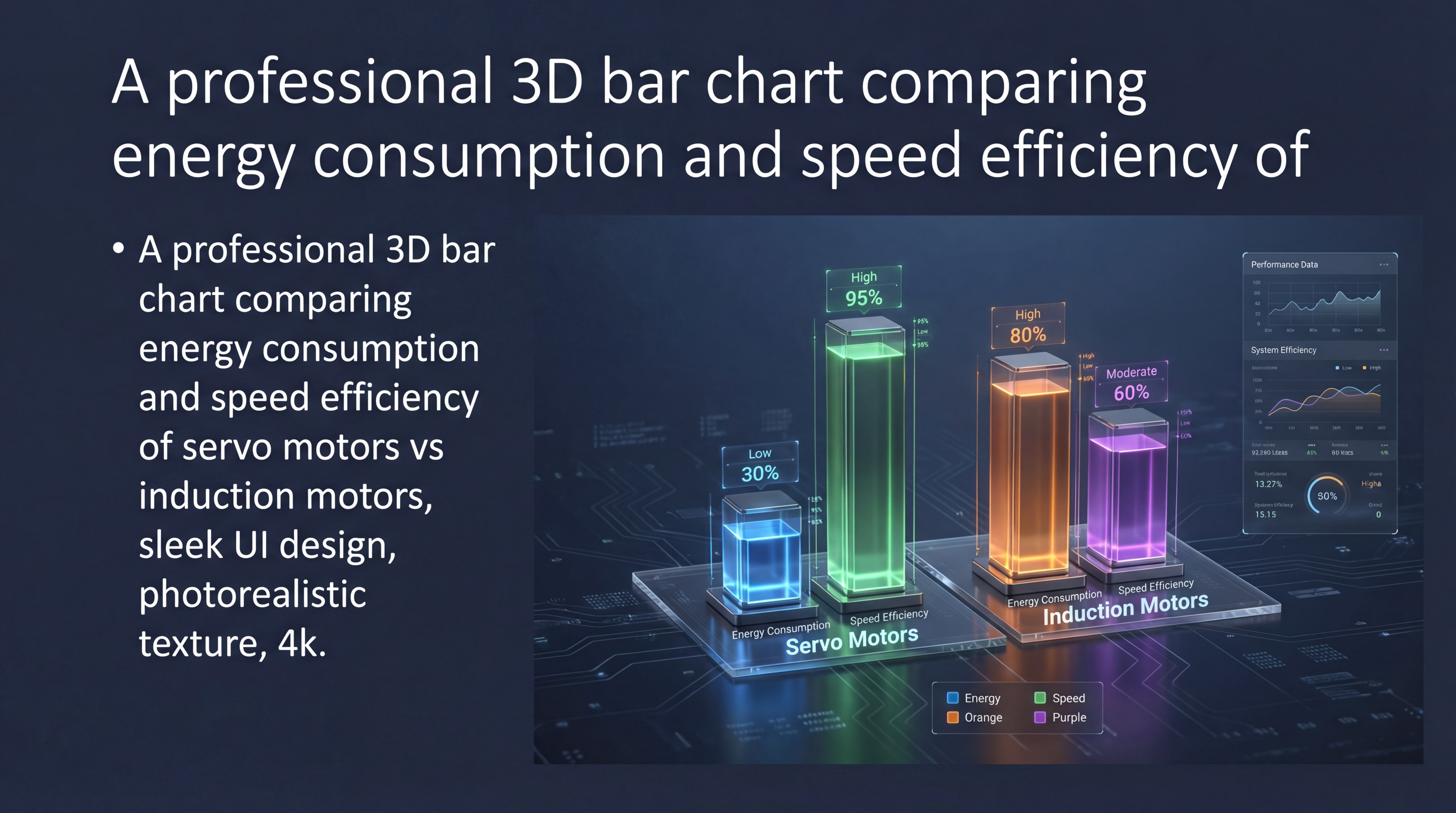

Is a servo motor packaging machine more energy efficient?

A servo motor packaging machine is more energy efficient because it only consumes power when it is actively performing a movement. Traditional motors often run continuously, wasting energy during dwell periods or when the machine is idling.

How do servo drives manage power consumption?

Servo drives manage power consumption by modulating the current sent to the motor based on the actual load requirements. This precision ensures that no excess energy is dissipated as heat, which also protects the electronics.

Here is why it matters for your overhead.

- Lower electricity bills for the facility.

- Reduced heat load on the factory floor.

- Extended lifespan of electrical components.

Can regenerative braking save your facility costs?

Regenerative braking can save costs by capturing the energy generated during the motor’s deceleration and feeding it back into the system. In high-speed packaging, where stop-start cycles are frequent, this energy recovery adds up to significant savings.

Believe it or not, this technology pays for itself.

- Recaptured energy powers other machine functions.

- Reduced wear on mechanical braking systems.

- Smaller carbon footprint for your operations.

Key Takeaway: Energy efficiency isn’t just about going green; it’s a direct reduction in your operational overhead that improves your profit margins.

| Efficiency Metric | Servo Performance |

|---|---|

| Idle Power | Near-zero consumption |

| Operational Power | Dynamic load matching |

| Heat Output | Significantly lower than AC motors |

Modern servo systems turn your packaging line into a smart energy consumer, optimizing power usage for every single bag produced.

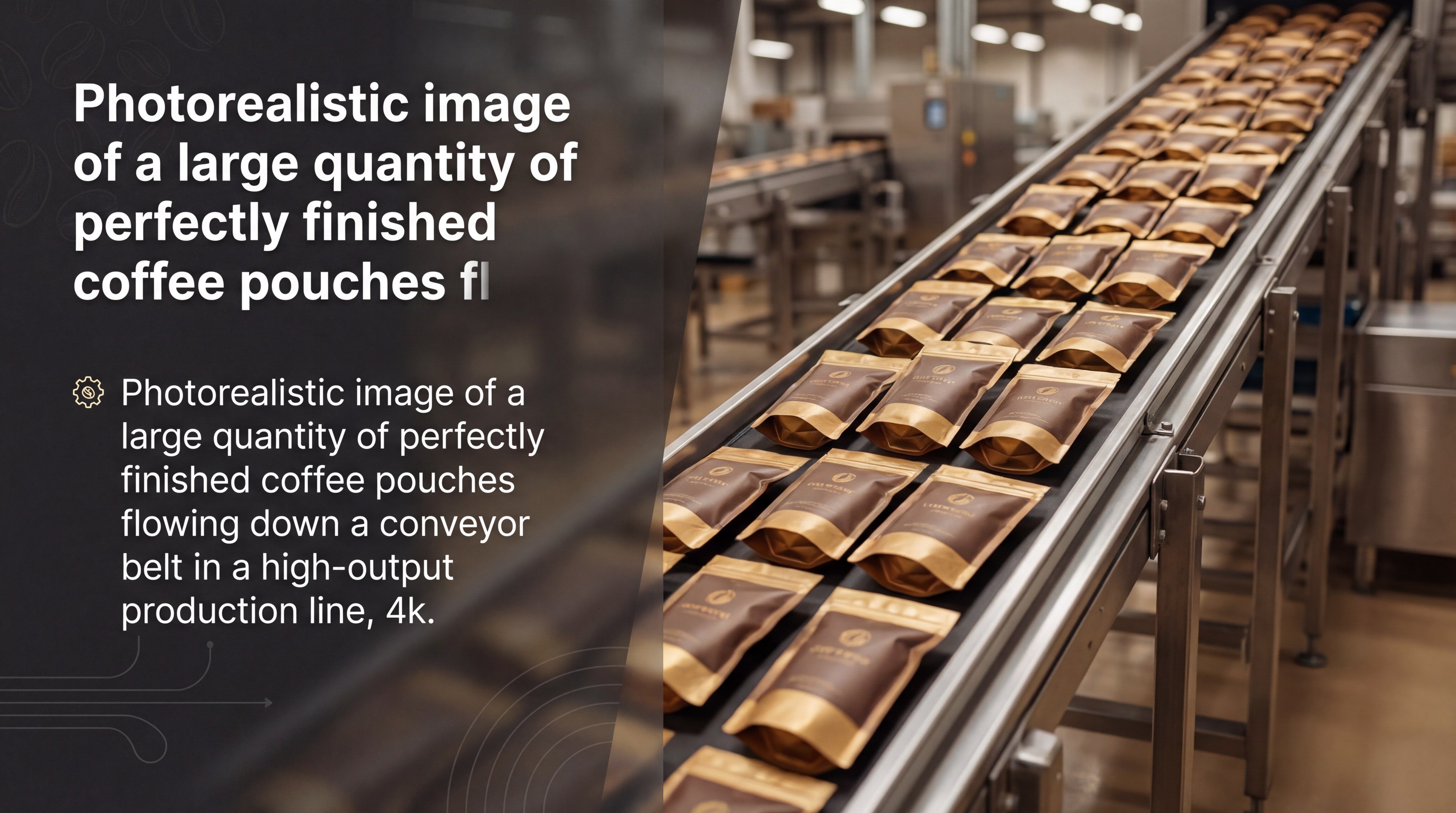

How does a servo motor packaging machine handle various speeds?

A servo motor packaging machine handles various speeds with ease because it maintains consistent torque across its entire RPM range. This allows you to run the machine slowly during testing and ramp up to maximum speed without losing accuracy or power.

Why is ramp-up and ramp-down time important?

Ramp-up and ramp-down times are critical because they determine how quickly your machine reaches its “sweet spot” of production. Servos allow for aggressive acceleration curves that get you to full speed in a fraction of the time required by standard drives.

Let me explain how this impacts short production runs.

- Faster start-ups after a pause.

- Controlled stops to prevent product spilling.

- Smooth transitions between different speed tiers.

Can servos maintain torque at high RPMs?

Servos maintain torque at high RPMs, ensuring that the sealing and cutting mechanisms have enough force to operate cleanly even at the top end of the machine’s capability. Traditional motors often lose torque as speed increases, leading to poor seal quality.

Here is the truth: consistency is king.

- Consistent seal integrity at all speeds.

- No “stalling” during high-speed film pulls.

- Uniform product quality regardless of output rate.

Key Takeaway: Flexibility in speed management allows you to adapt to different production demands without sacrificing the quality of your finished packaging.

| Speed Capability | Benefit |

|---|---|

| Variable Speed Control | Seamless ramp-up/down |

| Torque Consistency | High-speed reliability |

| Low-speed Precision | Easier troubleshooting and setup |

The ability to maintain performance at both ends of the speed spectrum makes the servo-driven machine the most versatile tool in your facility.

Is a servo motor packaging machine better for delicate items?

A servo motor packaging machine is better for delicate items because it allows for “S-curve” acceleration, which softens the start and end of every movement. This prevents the jerky motions that often cause fragile products, like crackers or dried herbs, to break during the filling process.

How do gentle acceleration curves prevent damage?

Gentle acceleration curves prevent damage by gradually increasing the speed of the product delivery system rather than snapping it into motion. This control ensures that the product settles correctly in the bag without hitting the sides or bottom too hard.

Keep this in mind: your product quality is your reputation.

- Lower percentage of “crushed” product.

- Better presentation for premium items.

- Ability to pack fragile items at higher speeds.

Can torque limits protect your product integrity?

Torque limits can protect product integrity by sensing if there is an obstruction in the sealing jaws or the hopper. If the motor encounters resistance above a set threshold, it stops immediately to prevent damage to the product or the machine.

Here’s why it matters: safety for your product and your hardware.

- Automatic jam protection.

- Reduced waste from crushed packages.

- Protection of expensive machine components.

Key Takeaway: Precision control over motion profiles allows you to handle sensitive products with the “soft touch” needed to maintain their value.

| Protection Feature | Impact on Quality |

|---|---|

| S-Curve Motion | Eliminates jarring impacts |

| Adjustable Torque | Prevents crushing in seals |

| Precision Dwell | Perfect settling of products |

By managing the physics of motion, servo motors ensure that speed never compromises the physical integrity of your goods.

Does a servo motor packaging machine offer better scalability?

A servo motor packaging machine offers better scalability because its modular software-driven control makes it easy to add new features or synchronize with additional equipment. As your business grows, you can integrate these machines into larger, more complex automated lines without a total system overhaul.

Is it easier to integrate with upstream systems?

Integration with upstream systems is easier because servo controllers use standard communication protocols like EtherCAT or Profinet. This allows your packaging machine to “talk” to your weighing systems, metal detectors, and conveyors in real-time.

Think about the possibilities for a fully automated plant.

- Seamless data sharing across the line.

- Automatic speed matching between machines.

- Centralized control of the entire production floor.

Can you add multilane capacity more effectively?

You can add multilane capacity more effectively because each lane can be controlled by its own servo motor, allowing for independent operation and synchronization. This ensures that a problem in one lane doesn’t necessarily have to stop the entire machine.

Consider this: growth without growing pains.

- Independent lane reject systems.

- Scalable output for different product sizes.

- Easier maintenance on individual lanes.

Key Takeaway: Modular digital controls ensure that your initial investment can evolve alongside your production needs, protecting you from technical obsolescence.

| Scalability Factor | Benefit |

|---|---|

| Modular Software | Easy feature updates |

| Standard Protocols | Simplified system integration |

| Multi-Axis Support | Efficient multilane expansion |

Investing in a scalable platform means you are buying a solution for today that won’t become a bottleneck tomorrow.

What makes a servo motor packaging machine a smart investment?

A servo motor packaging machine is a smart investment because the higher upfront cost is quickly offset by the reduction in labor, maintenance, and material waste. Over a three-to-five-year period, the total cost of ownership (TCO) for a servo system is significantly lower than that of a mechanical equivalent.

How does the total cost of ownership compare?

The total cost of ownership is lower because the machine produces more sellable units per hour while requiring fewer man-hours for maintenance and setup. When you calculate the cost per package, the efficiency of a servo system becomes undeniable.

Check out these points before finalizing your budget.

- Lower labor costs for setup and cleaning.

- Fewer expensive mechanical spare parts.

- Higher overall equipment effectiveness (OEE).

Why is data collection easier with digital drives?

Data collection is easier because every servo drive is a source of information, providing metrics on torque, speed, and energy usage in real-time. This data allows for “predictive maintenance,” where you can fix a problem before it causes an actual breakdown.

Here’s why it matters: knowledge is power.

- Real-time performance monitoring.

- Identification of production bottlenecks.

- Data-driven decision-making for ROI.

Key Takeaway: A servo-driven system is a financial tool that uses data and efficiency to pay for itself through increased production capacity.

| Investment Metric | Servo Machine | Mechanical Machine |

|---|---|---|

| Initial Cost | Higher | Lower |

| Maintenance Need | Low | High |

| Long-term ROI | Exceptional | Diminishing |

While the initial price tag may be higher, the long-term profitability of servo technology far outweighs the short-term savings of older designs.

Can a servo motor packaging machine optimize film usage?

A servo motor packaging machine optimizes film usage by maintaining constant tension and eliminating the “slip” that causes wasted material during startup and stop phases. Precise control over the pull-length ensures that you are not using a single millimeter more of expensive packaging film than necessary.

Does tension control prevent film breakage?

Tension control prevents film breakage by using the servo’s sensitivity to adjust the feed rate if the film becomes too tight or too loose. This is especially important when using thinner, more sustainable, or cost-effective films that are prone to tearing.

But that’s not all: better aesthetics for your brand.

- Ability to use thinner (cheaper) films.

- Reduced downtime from film snaps.

- Consistent seal thickness.

How does waste reduction impact your bottom line?

Waste reduction impacts your bottom line by saving thousands of dollars in material costs over the course of a year. When every bag is exactly the right length and every print is perfectly aligned, your “scrap” rate drops to near zero.

Think about it: every millimeter saved is money in your pocket.

- More bags per roll of film.

- Reduced disposal costs for waste material.

- Higher yield from every production run.

Key Takeaway: Maximizing your material yield is one of the fastest ways to improve the profitability of every unit you sell.

| Waste Category | Servo Impact |

|---|---|

| Film Over-pull | Eliminated by precision feeding |

| Misaligned Print | Corrected by registration logic |

| Film Breakage | Prevented by active tensioning |

Efficiency in material usage is a hidden profit center that many manufacturers overlook until they see the data from a servo-driven line.

Why choose a Newideapack servo motor packaging machine?

A servo motor packaging machine from Newideapack is designed with high-grade components and proprietary control logic to ensure maximum durability and speed. We focus on engineering solutions that are not just fast, but also intuitive for your operators to use and maintain.

How does our engineering enhance speed?

Our engineering enhances speed by optimizing the weight-to-strength ratio of all moving parts, allowing the servo motors to accelerate even faster. We use high-speed communication backplanes that ensure zero-latency between the sensors and the motors.

Here is why it matters: performance you can rely on.

- Industry-leading cycle times.

- Vibration-free operation at high RPM.

- Robust construction for 24/7 operation.

Do we provide global support for your facility?

We provide global support for your facility to ensure that your machine stays running at peak performance regardless of your location. From remote diagnostics to on-site training, Newideapack is committed to your long-term success.

But wait, there’s more to our partnership.

- Readily available spare parts.

- Expert technical assistance.

- Comprehensive training for your staff.

Key Takeaway: Partnering with Newideapack gives you access to both world-class machinery and the expert support needed to keep your production line running at maximum speed.

| Service Pillar | Newideapack Advantage |

|---|---|

| Engineering | Optimized for high-speed cycles |

| Support | Global reach and remote diagnostics |

| Training | Expert-led operator instruction |

Choosing Newideapack means investing in a partnership that prioritizes your production uptime and long-term growth.

Conclusion

By implementing a servo motor packaging machine, you solve the critical issues of mechanical lag, high maintenance costs, and material waste that plague traditional production lines. At Newideapack, we specialize in delivering the high-speed precision your business needs to scale effectively in today’s competitive landscape. Whether you are looking to increase your PPM or reduce your energy footprint, our engineering team is ready to design the perfect solution for your facility.

FAQ

Can I upgrade my old mechanical machine to a servo system?

Yes, it is possible through a retrofit, though it is often more cost-effective to invest in a new, purpose-built servo motor packaging machine to ensure all components are optimized for high speed.

What’s the best way to maintain a servo-driven machine?

The best way is to keep the electrical cabinets clean and perform regular software backups, as these machines require significantly less physical lubrication than mechanical ones.

How do I know if I need a full servo or a hybrid system?

If your production requires frequent bag size changes and high precision, a full servo motor packaging machine is usually the best choice for ROI.

Can a servo motor packaging machine handle heavy products?

Absolutely. Servos provide high torque at low speeds, making them ideal for heavy filling applications where traditional motors might struggle.

What is the expected lifespan of these motors?

With proper electrical protection and cooling, servo motors are designed to last for over 20,000 hours of operation before requiring significant service.

To see how our technology can transform your production line?

please contact us today for a custom consultation and quotation. Your path to maximum efficiency starts with the right drive technology.